R81 regulator and c81 regulator configurations, R81 regulator and c81 configurations – Norgren U.L. Listed Beverage Regulators User Manual

Page 6

Littleton, CO USA

Phone 303-794-2611

Fax 303-795-9487

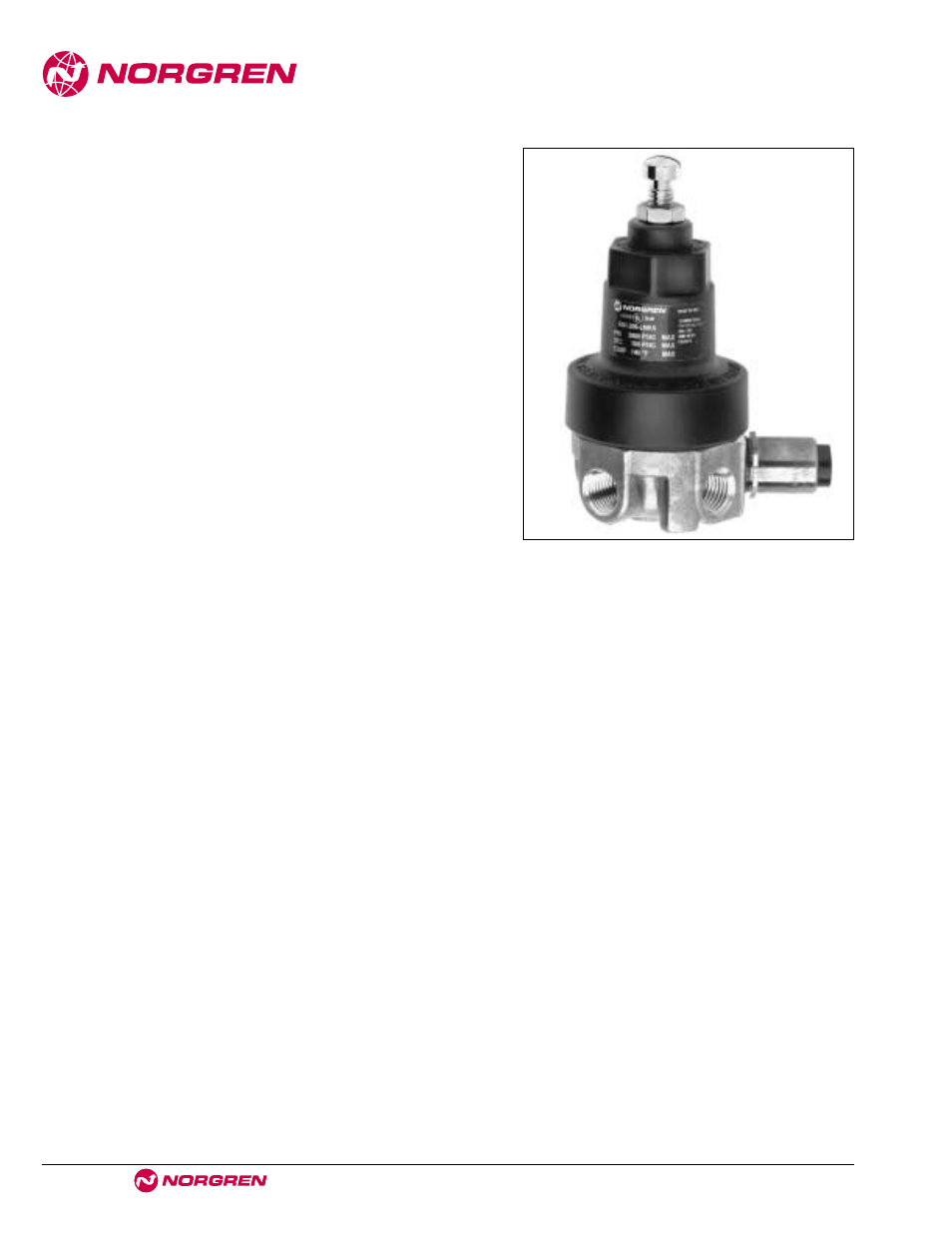

R81 Regulator and C81 Configurations

●

Underwriters Laboratories, Inc. listed (file number

SA1089)

●

The R81 regulator and C81 regulator configurations

with integral relief valve and outlet check valves meet

the requirements of paragraphs 4.5 and 4.6 of NSDA

Pamphlet TD02, Installation and Operational

Procedures for Pressurized Soft Drink Dispensing

Systems, dated July, 1980.

●

Integral relief valve easily replaced without

disassembly of regulator and without affecting relief

pressure setting

●

Back flow check valve, or manifold with integral

check valve at each outlet, can be installed in

regulator outlet port. Manifolds available with 3 or 5

outlets and include one outlet cap.

●

Relieving diaphragm allows outlet pressure setting to

be reduced even though the system is dead-ended.

Pressure downstream of check valves will not be

reduced.

●

Easily replaceable valve cartridge contains valve,

valve seat, valve spring, and filter element

●

Two high pressure ports (inlet and primary gauge)

and two regulated pressure ports (outlet and

secondary gauge)

●

Diametrically opposite inlet ports facilitate

manifolding for multiple dispensing applications.

Each manifolded regulator operates independently as

though attached directly to the gas supply source.

●

Bonnet wrench hex same size as tank adapter - one

wrench fits both

UL Listed, Cylinder Gas Pressure Regulator

1/4" PTF Port Size, CO

2

Regulator for Soft Drink Dispensing Systems

Technical Data

Fluid: Carbon dioxide. The R81 regulator is designed for use in soft drink

dispensing systems to control cylinder gas (carbon dioxide, nitrogen, air)

pressure to the product containers. Other Norgren regulators (R84 for soft drink

carbonators, R82 for beer, R83 for industrial cylinder gases) are available for

use in other systems.

Maximum pressure: 3000 psig (207 bar)

Operating temperature: 0° to 140°F (-18° to 60°C)

Integral relief valve cracking pressure:

130 ± 4 psig (9.0 ± 0.28 bar)

Materials:

Body: Brass

Bonnet: Zinc

Valve cartridge: Teflon, brass, stainless steel

Diaphragm: Acetal and nitrile

Relief valve: Brass, polycarbonate, nitrile, aluminum

Seals: Nitrile

ALE-12-6

See Section ALE-25 for Accessories