WIKA 702.03.100 User Manual

Page 15

GB

WIKA operating instructions differential pressure gauge, model 702.03.100

15

2367781.03 06/2013 GB/D/F/E

Commissioning

During the commissioning process pressure surges must be avoided at all costs.

Open the shut-off valves slowly.

6. Commissioning, operation / 7. Options and accessories

7. Options and accessories

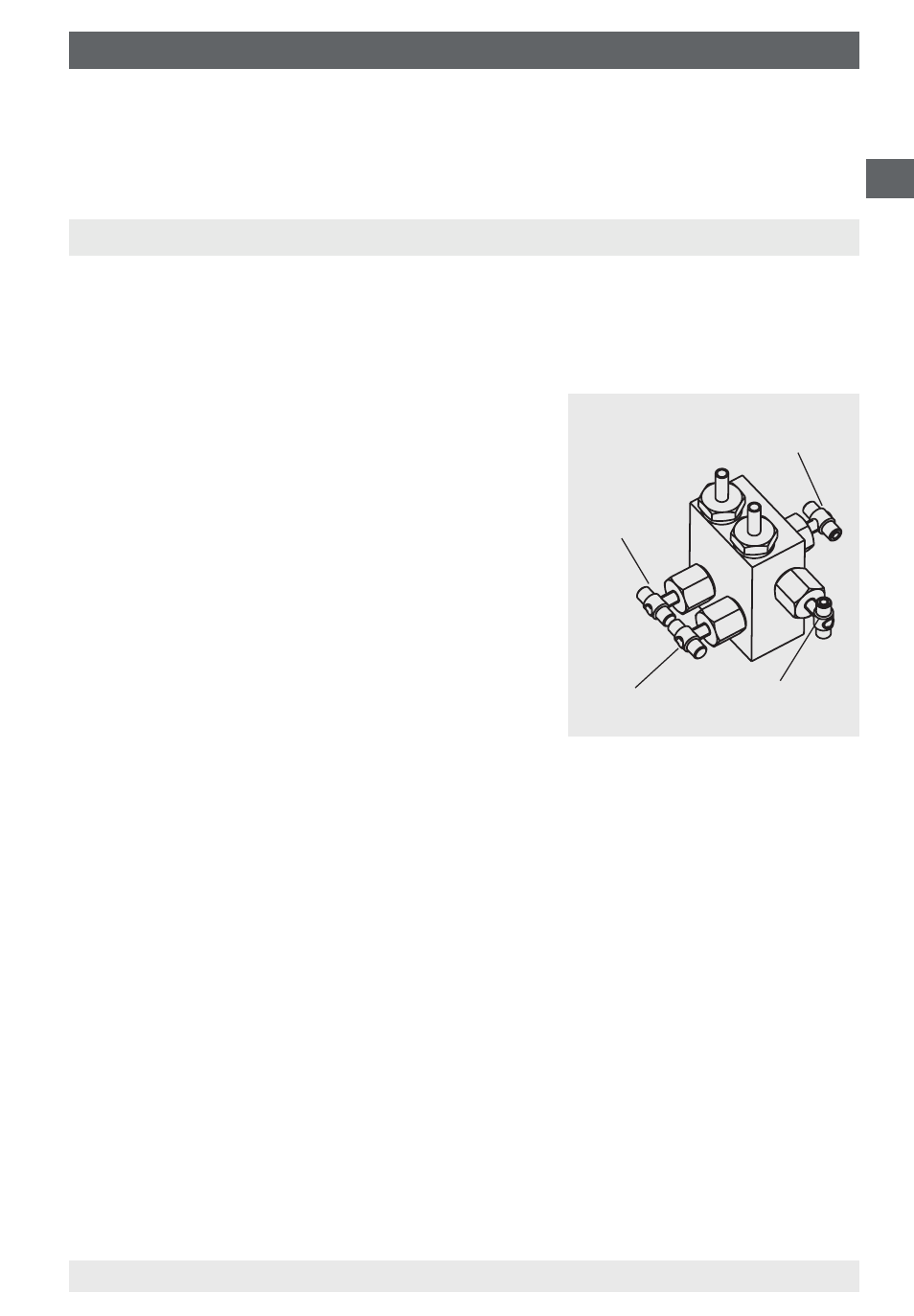

7.1 4-way valve manifold

■

Isolation of the ⊕ and ⊖ process lines for removing or testing the measuring

instrument without interrupting the running process operation.

Protection of the unit against excessive

overpressure loading, such as in pressure

tests and undefined operating conditions

(including intermittent shutdown).

■

Pressure compensation for zero point

checking with running processes, and avoid-

ing one-sided overpressure loading during

start-up and operation phases (with opened

pressure compensating valve).

■

Venting the measuring lines with liquid me-

dia and flushing of the measuring lines, in

order to remove contamination.

Specifications for handling

■

Sequence of operations to start measurement

1. Open the pressure compensating valve (middle valve spindle)

2. Open the shut-off valve for the negative media chamber (⊖, right-hand valve)

and the positive media chamber (⊕, left-hand valve)

3. Close the pressure compensating valve

■

Sequence of operations to flush/vent the measuring lines

1. Start: Open the shut-off valve for the ⊕ and ⊖ media chamber, open the

pressure compensating valve and vent valve

2. Finish: Close the pressure compensating valve and vent valve

■

Sequence of operations to finish measurement (also temporary shutdown)

1. Open the pressure compensating valve

2. Close the shut-off valve for the ⊕ and ⊖ media chamber

Vent valve

Shut-off valve

⊖

side

Shut-off valve

⊕

side

Pressure com-

pensating valve