WIKA 702.03.100 User Manual

Page 14

GB

WIKA operating instructions differential pressure gauge, model 702.03.100

14

2367781.03 06/2013 GB/D/F/E

6. Commissioning, operation

Information

For the safety circuit, which will switch off the heating if the

steam generator falls below the minimum flow, only the normally

open contact of the changeover switch should be connected (i.e.

with Δp = 0 open circuit)!

6.3 Switch point setting and zero point test

The switch points are set at the factory when the set points are given.

The adjustment of the switch point is made by the adjustment screws accessible

from the front. An assistant scale over 270 ∢° enables a relatively accurate

adjustment of the switch points and indicates the set point that is currently

adjusted.

For contact adjustment, the vent plugs in the snap-in disc should be removed. By

turning the contact adjustment screws using a screwdriver the desired switch point

can be set.

If an even more accurate switch point setting is required, a reference standard

should be used for the adjustment.

Afterwards, the vent plugs should be pressed back into the snap-in disc.

Following the setting and the testing of the switch point in the equipment, the

instrument must be sealed and the set value marked on the instrument.

Zero point test

By opening a pressure compensating valve (see point 7.1 on page 15) a zero

point check during the running process is possible.

The medium flows from the higher-pressure side towards the opposite side and

the differential pressure at the gauge drops to zero.

By opening the pressure compensating valve, the differential pressure indicator

must drop to zero, i.e. into the area of the zero-point tolerance bar. The instrument

function is thus in order. With possible deviations, which are outside the tolerance

bar, a zero adjustment can be made using the standard built-in adjustable pointer.

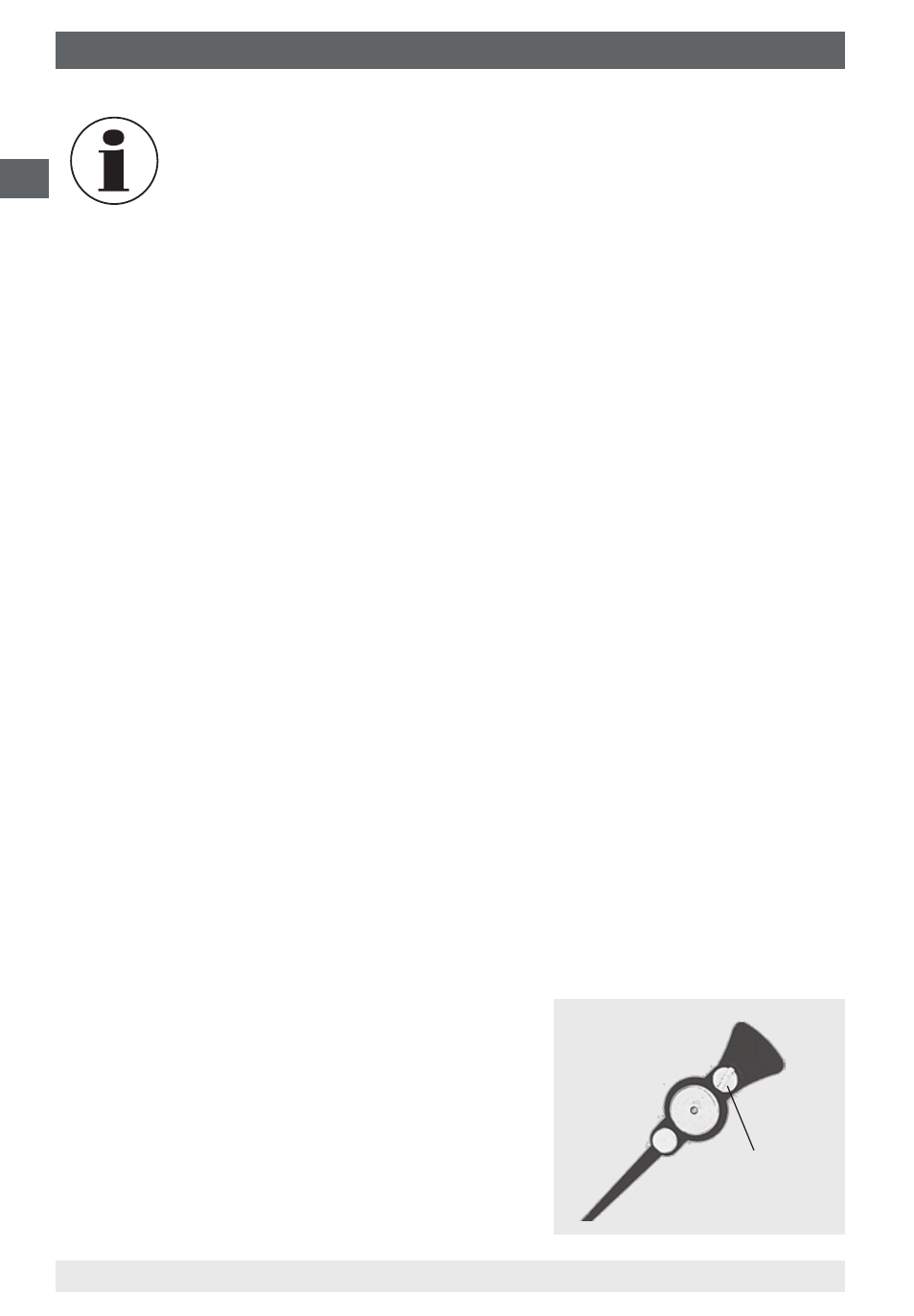

To do this the snap-in disc should be lifted off,

using a screwdriver in the appropriate impression/

recess.

The zero adjustment is achieved by turning the

slotted screw on the adjustable pointer.

Afterwards, the snap-in disc should replaced on

the case.

The differential pressure will be displayed again

as soon as the pressure compensating valve is

closed once more.

Slotted screw