Commissioning, operation – WIKA 702.03.100 User Manual

Page 11

GB

WIKA operating instructions differential pressure gauge, model 702.03.100

11

2367781.03 06/2013 GB/D/F/E

6. Commissioning, operation

2123541.01

■

Prior to the installation of the pressure gauge, clean the measuring lines

thoroughly by tapping and blowing or rinsing

■

Protect measuring instruments from contamination and high temperature

changes!

■

The pressure gauge must be mounted free from vibration and should be

aligned so that it is easy to read. It is recommended that an isolation device is

interposed between the pressure tapping point and the pressure gauge, which

will enable the replacement of the pressure gauge and a zero point check while

the plant is running. The instruments should be protected against coarse dirt

and wide fluctuations in ambient temperature.

■

Correct sealing of the connections must be made using suitable flat gaskets,

sealing rings or WIKA profile sealings. In order to orientate the gauge so that

the on-site display can be read as well as possible, a clamp socket or union nut

should be used. When screwing on and unscrewing the pressure gauges they

should not be gripped by the case, but rather only on the spanner flats of the

connection!

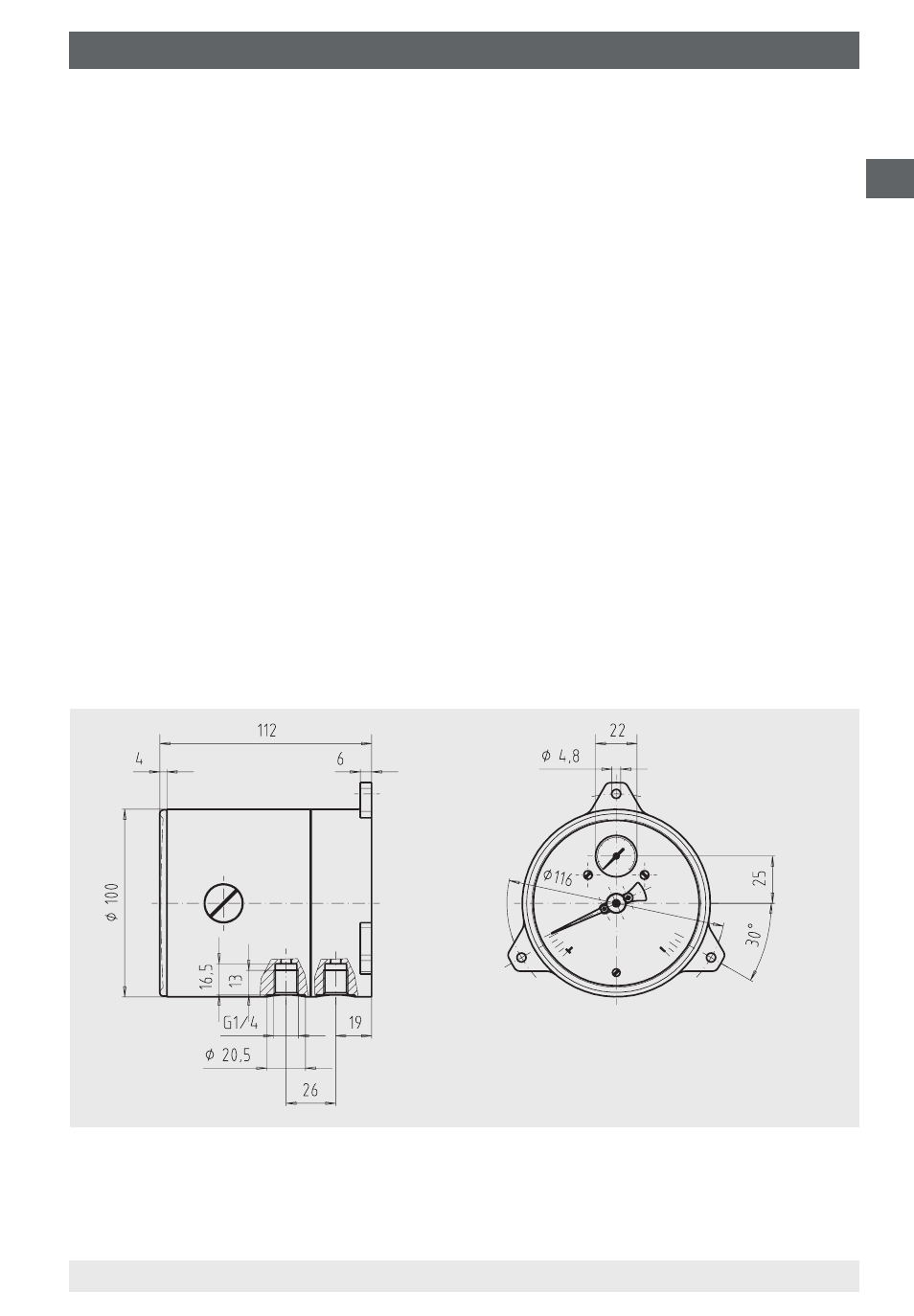

Wall mounting

Mounting using three integrally cast mounting lugs