DuraVent Type B Gas Vent User Manual

Page 20

20

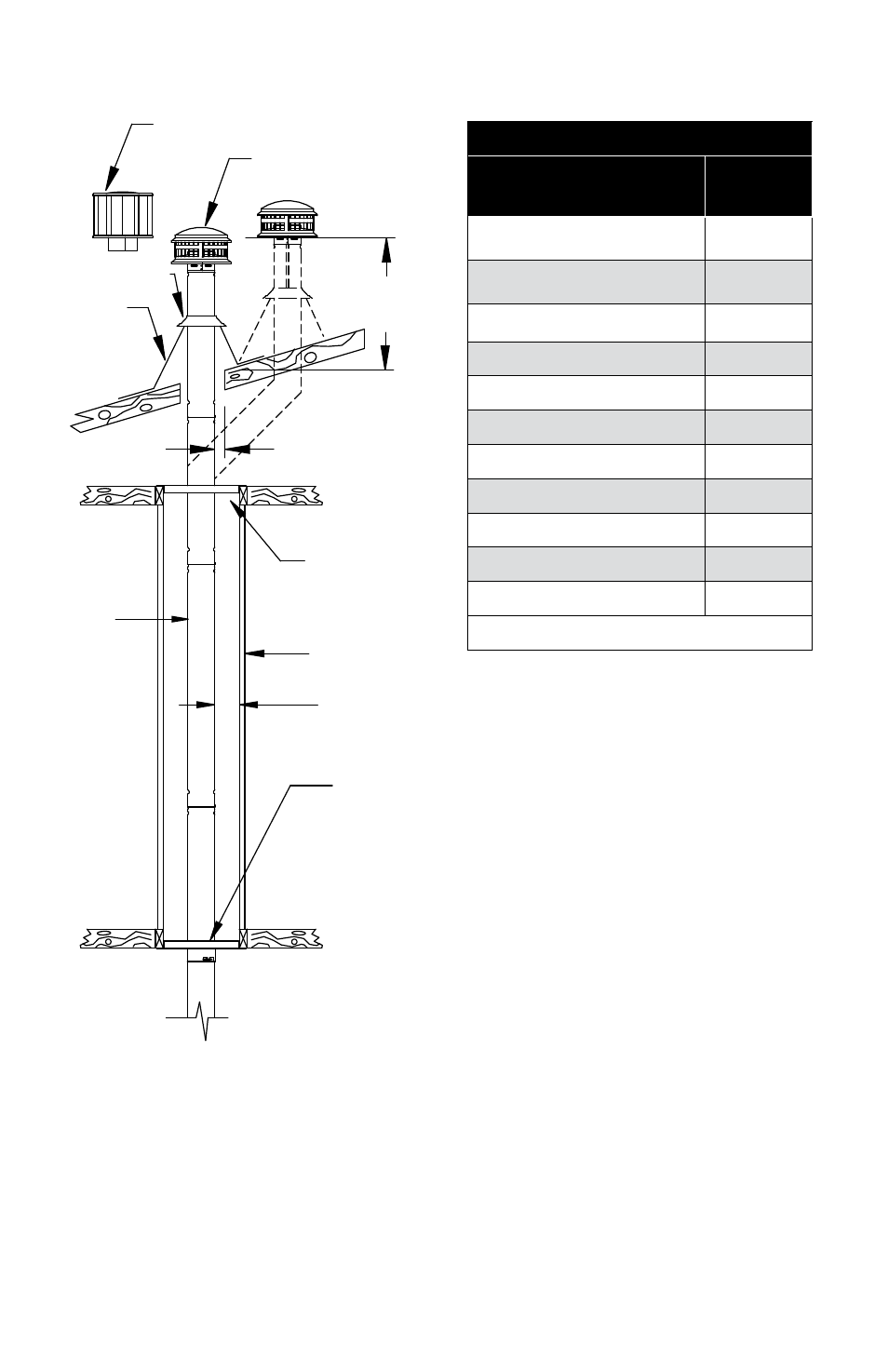

TABLE 1

Roof Pitch

Minimum

Height*

FLaT TO 7/12

1.0

OVER 7/12 TO 8/12

1.5

OVER 8/12 TO 9/12

2.0

OVER 9/12 TO 10/12

2.5

OVER 10/12 TO 11/12

3.25

OVER 11/12 TO 12/12

4.0

OVER 12/12 TO 14/12

5.0

OVER 14/12 TO 16/12

6.0

OVER 16/12 TO 18/12

7.0

OVER 18/12 TO 20/12

7.5

OVER 20/12 TO 21/12

8.0

*THIS REQUIREMENT COVERS MOST INSTALLATION

Gas venting systems using vent caps

listed by underwriters’ may terminate in

accordance with this vent termination table.

Where the vent passes through the roof,

the roof sheathing is cut away to provide a

minimum clearance of 1 inch from the vent

pipe. Straight lengths of pipe are run up about

a foot above the roof. a roof flashing is placed

down over the pipe, and adjusted so the

flashing fits tightly against the roof, with the

vent pipe held in a position maintaining the

1-inch minimum clearance from combustibles.

The flashing is then nailed to the roof. a non-

hardening sealant may be used around the

edges of the flashing base where it meets the

roof. non-hardening sealant is placed around

the joint between the flashing and the vertical

vent pipe, and the storm collar is then placed

over this joint to make a watertight seal. The

storm collar serves as a counter-flashing to

give additional protection.

HIGH WInD cap

D

uRa

c

ap

STORM

cOLLaR

FLaSHInG

pIpE

ROunD pIpE

SEE TaBLE 1

1 IncH MInIMuM

cLEaRancE

FIRESTOp

SpacER

EncLOSuRE

WaLL

1 IncH

MInIMuM

cLEaRancE

GaS VEnT

SuppORT