Adjustable elbows – DuraVent Type B Gas Vent User Manual

Page 11

11

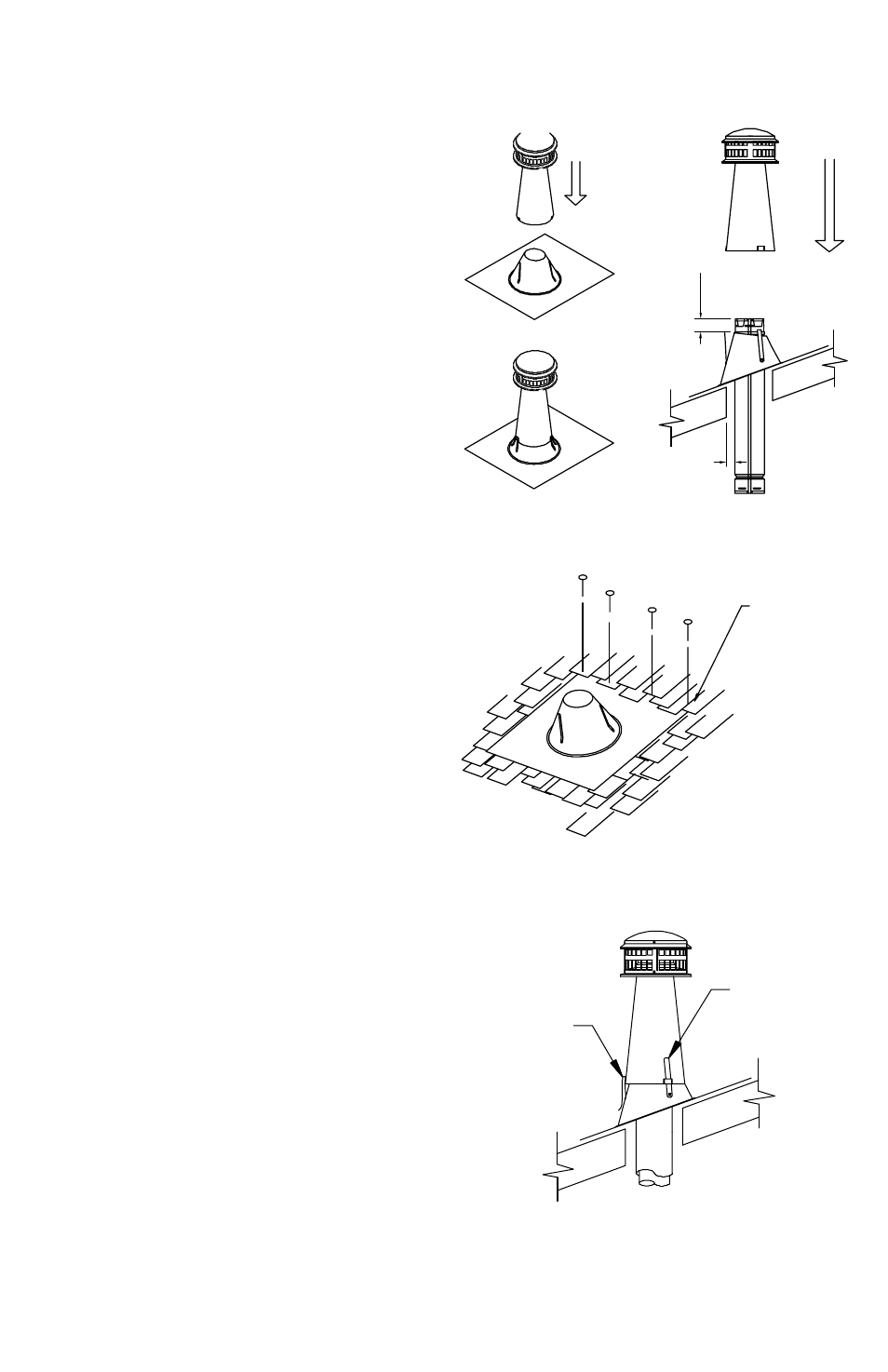

Figure 15

Figure 16

Figure 17

Figure 18

of the roof where the system is to penetrate,

using a plumb bob or level.

3. Hole. Remove sufficient roofing material

to cut a hole in the roof which will allow a

minimum of 1 inch air space between the

B-Vent and combustible roofing materials.

4. Flashing. position the Flashing so the hole

is directly over the end of the pipe, as shown in

Figure 16. Run the top edge of the Flashing

under the roof covering, nail as required, and

seal with a non-hardening sealant, as shown in

Figure 17. Seal all nail heads.

5. Height. add sufficient pipe Sections of

B-Vent until the system terminates 1-1/2” to 3”

above the collar of the Flashing as shown in

Figure 16.

6. Top Cone. Slip the Top cone over the

Flashing, so the vertical straps on the Flashing

coincide with the slots at the base of the

cone. Slip the straps up through the slots as

shown in Figure 18. adjust the Top cone to

a generally vertical position. Holding the Top

cone in position, bend the straps down as

shown.

7. This completes the installation. conduct

a final inspection of the job to ensure proper

joints, correct procedures, sealed nail heads,

etc.

ADJUSTABLE ELBOWS

1. Purpose. This section furnishes

supplemental information concerning

adjustable Elbows, both 90° and 45°/60°.

2. Connections. In addition to twist locking

the elbows, the connection may be further

secured by using sheet metal screws at the

joint where the male and female parts overlap,

provided that the screws DO NOT penetrate

the inner liner as shown in Figure 19. One

screw per joint is normally sufficient. use #8

pan Head sheet metal screws which are no

longer than 1/4 inch. Wall Straps must be

Run TaBS On

FLaSHInG up THRu

RaISED SLOTS On

cOnE

anD THEn

FOLD THEM

OVER TO HOLD

cOnE TO

FLaSHInG

1 1/2 to 3

IncHES

1 IncH

MInIMuM

appLy

WEaTHERpROOF

SEaLanT

BETWEEn

FLaSHInG anD

ROOF On aLL

SIDES anD TO naIL

HEaDS.