Preliminary installation of seal chamber cover, Caution – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 50

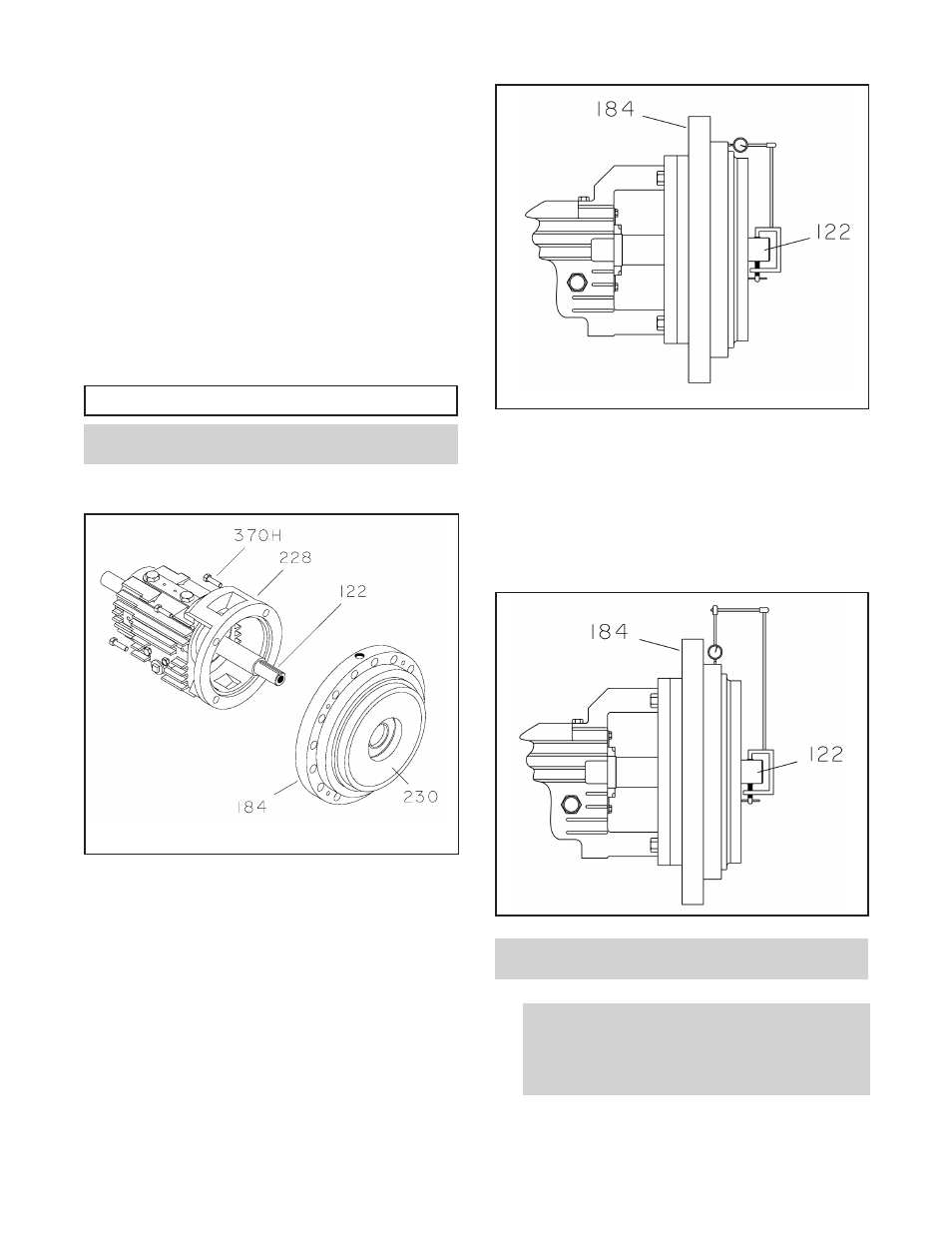

PRELIMINARY INSTALLATION OF

SEAL CHAMBER COVER

1.

Install eyebolt in tapped hole provided in seal chamber

cover (184) (Fig. 50).

2.

Rig sling to eyebolt and to overhead lifting device.

3.

Lift seal chamber cover (184) and position to align

with shaft (122).

4.

Install seal chamber cover (184) on bearing frame

assembly by guiding cover carefully over shaft (122)

and into bearing frame (228) lock.

5.

Install seal chamber cover/bearing frame bolts (370H)

and tighten evenly using alternating pattern. Torque

bolts to values shown in Table 7.

$

CAUTION

For runout checks, firmly support bearing frame

assembly in horizontal position, as shown in Fig. 36.

6.

Check seal chamber cover (184) face runout in the

following manner:

a.

Mount dial indicator on shaft (122) as shown in

Fig. 51.

b.

Rotate shaft (122) so indicator rides along the seal

chamber cover (184) gasket face for 360 degrees. If

total indicator reading is greater than 0.13 mm (.005

in.), determine cause and correct.

7.

Check seal chamber cover (184) lock runout in the

following manner:

a.

Mount dial indicator on shaft (122) as shown in

Fig. 52.

b.

Rotate shaft (122) so indicator rides along the seal

chamber cover (184) lock for 360 degrees. If total

indicator reading is greater than 0.13 mm (.005 in.),

determine cause and correct.

NOTE: If two dial indicators are available, steps 6

and 7 may be performed simultaneously.

!

The impeller and wear ring clearance setting

procedures must be followed. Improperly setting the

clearance or not following any of the proper

procedures can result in sparks, unexpected heat

generation, and equipment damage.

50

3910-1

1th IOM 5/08

Fig. 50

Fig. 51

Fig. 52