Maintenance of shaft seals – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 29

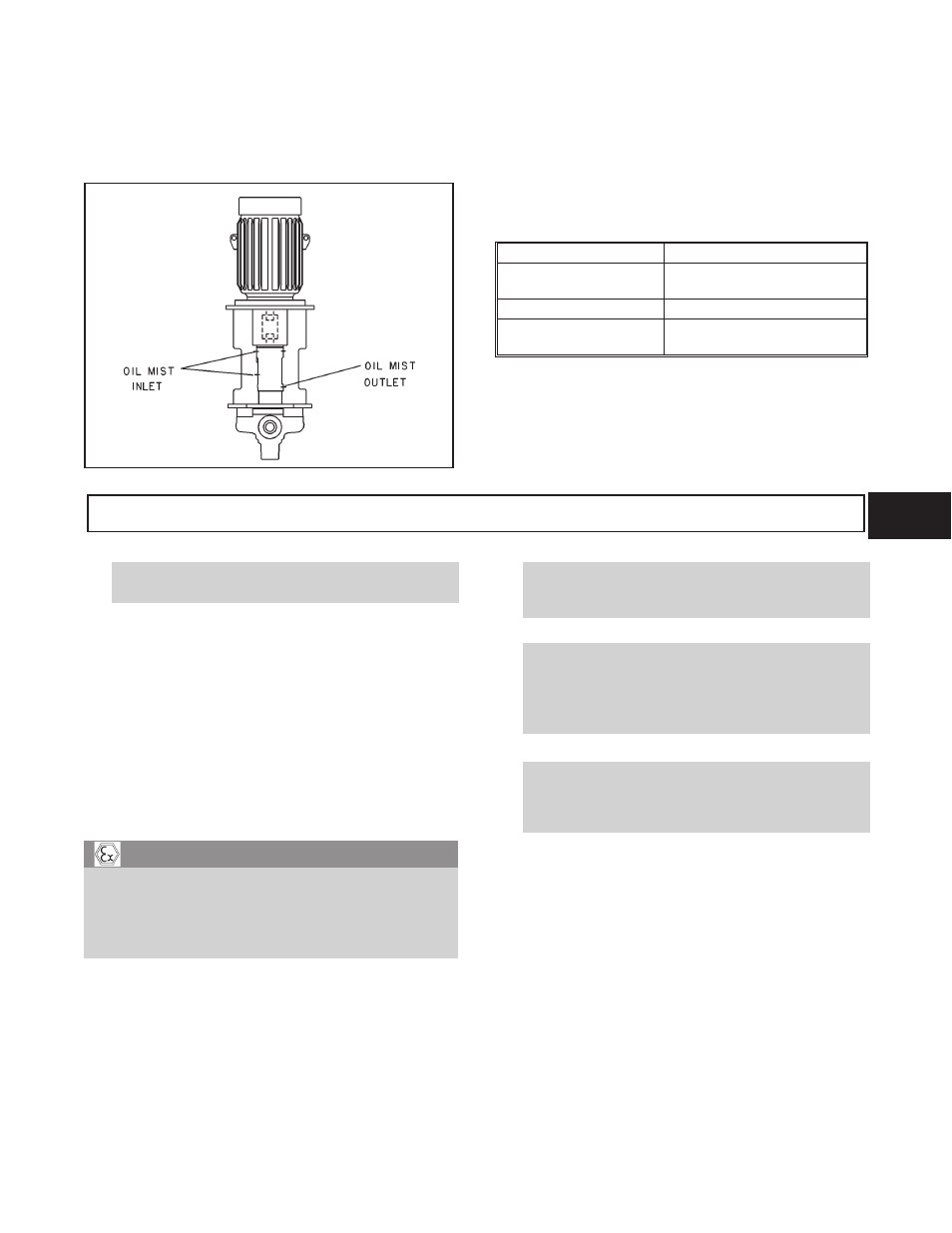

3.

Connect drain line to bottom tapped connection

(Fig. 12).

Oil mist lubrication is required above pumpage temperature

of 232°C (450°F), but may be used at lower temperature.

A high quality turbine oil with rust and oxidation inhibitors

should be used. For the majority of operational conditions,

bearing temperatures will run between 50°C (120°F) and

82°C (180°F). In this range, an oil of ISO viscosity grade

68 at 40°C (100°F) is recommended. If bearing tempera-

tures exceed 82°C (180°F), use ISO viscosity grade 100.

Some acceptable oils are:

Exxon

Teresstic EP68

Mobil

Mobil DTE 26 300 SSU

@ 40°C (100°F)

Sunoco

Sunvis 968

Royal Purpal

SYNFILM ISO VG 68

Synthetic Lube

MAINTENANCE OF SHAFT SEALS

!

The mechanical seal used in an ATEX classified

environment must be properly certified.

When mechanical seals are furnished by Goulds, a

manufacturer’s reference drawing is supplied with the data

package. This drawing should be kept for future use when

performing maintenance and adjusting the seal. The seal

drawing will also specify required flush liquid and

attachment points. The seal and all flush piping must be

checked and installed as needed prior to starting the pump.

The life of a mechanical seal depends on various factors

such as cleanliness of the liquid handled and its lubricating

properties. Due to the diversity of operating conditions it is,

however, not possible to give definite indications as to its

life.

s

!

WARNING

NEVER operate the pump without liquid supplied to the

mechanical seal. Running a mechanical seal dry, even

for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal

fails.

!

The mechanical seal must have an appropriate seal

flush system. Failure to do so will result in excess heat

generation and seal failure.

!

Cooling systems such as those for bearing

lubrication, mechanical seal systems, etc., where

provided, must be operating properly to prevent

excess heat generation, sparks and premature

failure.

!

Sealing systems that are not self purging or self

venting, such as plan 23, require manual venting

prior to operation. Failure to do so will result in

excess heat generation and seal failure.

3910-1

1th IOM 5/08

29

Fig. 12

5