Goulds Pumps 3910 11th ed. - IOM User Manual

Page 22

LUBRICATING BEARINGS

!

Bearings musts be lubricated properly in order to

prevent excess heat generation, sparks and

premature failure.

Grease Lubrication

Greased lubricated ball bearings are standard on the Model

3910 units.

The bearings are greased at the factory.

See Preventive Maintenance section for lubrication

recommendations.

Pure Oil Mist Lubrication

Pure oil mist is an optional feature for the Model 3910.

Follow oil mist generator manufacturer’s instructions. The

inlet and outlet connections are located on the side of the

bearing frame.

See Preventive Maintenance section for lubrication

recommendations and connection locations.

s

!

WARNING

Operation of the unit without proper lubrication will

cause bearing failure and pump seizure.

SHAFT SEALING WITH

MECHANICAL SEAL

!

The mechanical seal used in an ATEX classified

environment must be properly certified.

Pumps may be shipped with or without mechanical seal

installed. Cartridge type mechanical seals are commonly

used for this model. Cartridge seals are preset at the seal

manufacturer’s facility and require no field settings.

Cartridge seals installed by the user require disengagement

of the holding clips prior to operation, allowing the seal to

slide into place. If the seal has been installed in the pump

by Goulds, these clips have already been disengaged. For

other types of mechanical seals, refer to the seal

manufacturer’s instructions for installation and setting.

Connection of Sealing Liquid

!

The mechanical seal must have an appropriate seal

flush system. Failure to do so will result in excess heat

generation and seal failure.

!

Cooling systems such as those for bearing

lubrication, mechanical seal systems, etc., where

provided, must be operating properly to prevent

excess heat generation, sparks, and premature

failure.

!

Sealing systems that are not self purging or self

venting, such as plan 23, require manual venting

prior to operation. Failure to do so will result in

excess heat generation and seal failure.

For satisfactory operation, there must be a liquid film

between seal faces to lubricate them. Refer to seal

manufacturer’s drawing for location of taps. Some methods

which may be used to flush/cool the seal are:

•

Product Flushing - In this arrangement, the pumpage is

piped from the casing (and cooled in an external heat

exchanger when required) then injected into seal

chamber.

•

External Flush - A clean, cool compatible liquid is

injected from an outside source directly into seal

chamber. Flushing liquid must be at a pressure 0.35-1.05

kg/cm

2

(5-15 psi) greater than seal chamber pressure. Injection

rate should be 2-8 l/min. (

1

2

-2 GPM).

•

Other methods may be used which make use of multiple

gland connections and/or seal chamber connections.

Refer to documentation supplied with the pump,

mechanical seal reference drawing, and piping diagrams.

PRIMING PUMP

!

Pumps must be fully primed at all times during

operation.

Never start the pump until it has been properly primed.

Several different methods of priming can be used, depending

upon type of installation and service involved.

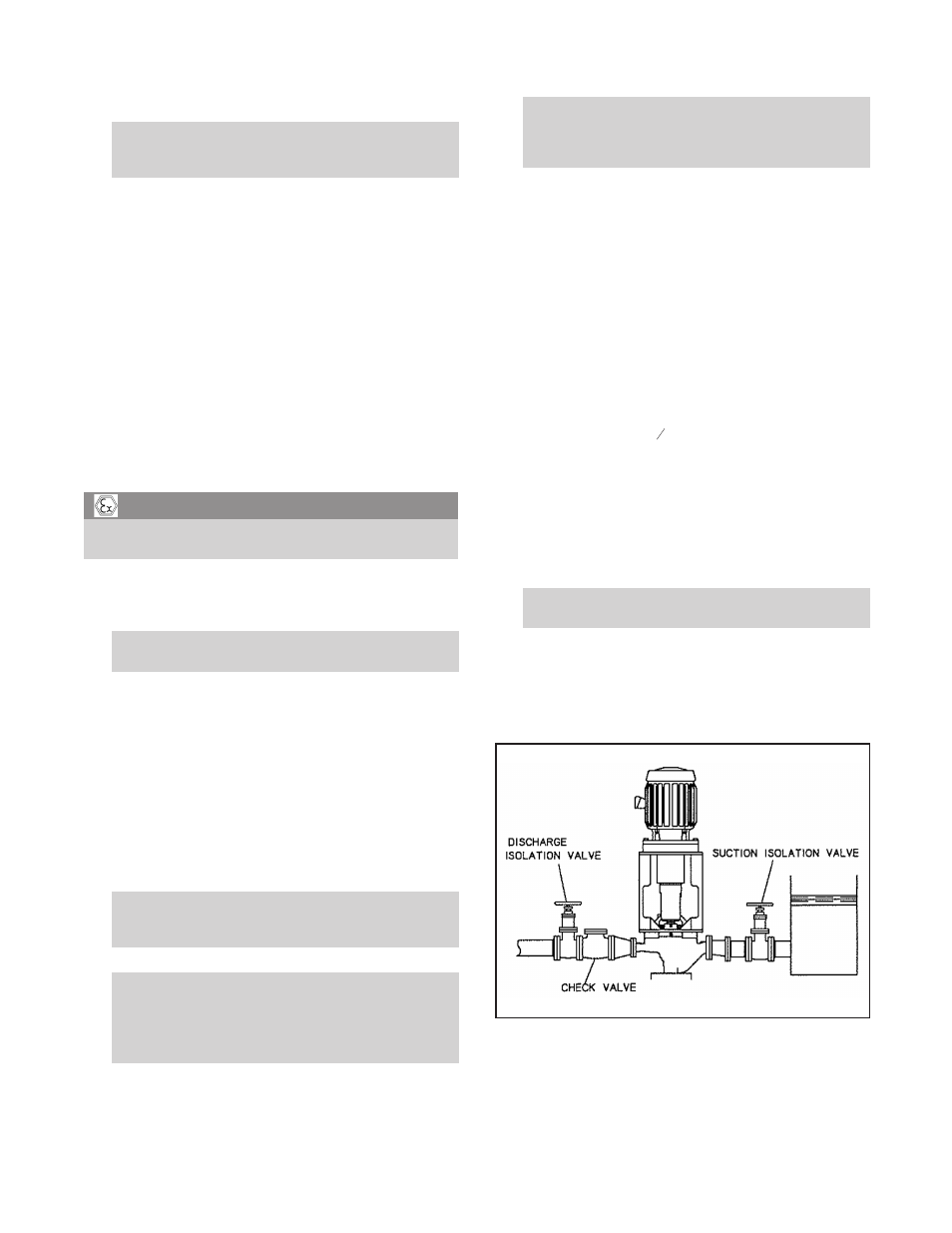

Suction Supply Above Pump

1.

Slowly open the suction valve (Fig. 8).

2.

Open air vents on the suction and discharge piping, casing,

seal chamber, and seal piping, if provided, until all air is

vented and only liquid flows out.

3.

Close the vents.

22

3910-1

1th IOM 5/08

Fig. 8