Caution – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 47

14. Install thrust bearing end cover (109A) over shaft

(122) and onto bearing frame (228). For SA pumps,

install thrust cover with the words “Top oil mist” on

top.

15. Install and tighten thrust bearing end cover/bearing

frame screws (370N) evenly to torque valves shown in

Table 7.

$

!

CAUTION

Do not over tighten thrust bearing end cover/ bearing

frame screws.

16. Determine axial end play as follows:

a.

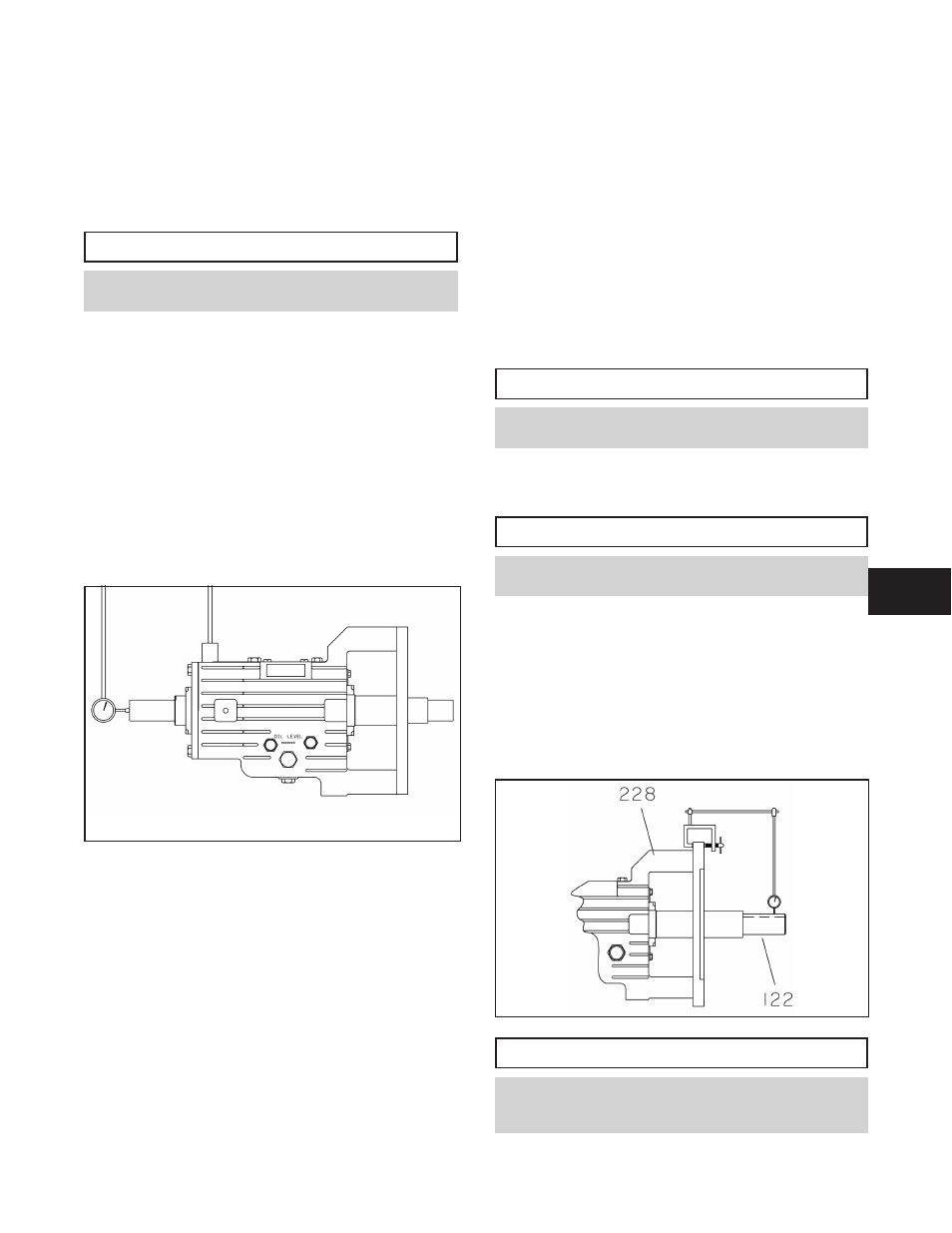

Mount dial indicator as shown in Fig. 43.

b.

Apply axial force to impeller end of shaft (122)

and firmly seat thrust bearing (112) against

shoulder in bearing frame (228).

c.

Apply axial force in opposite direction and firmly

seat thrust bearing (112) against thrust bearing end

cover (109A).

d.

Repeat steps b and c several times and record total

travel (end play) of rotating element.

e.

Total travel (end play) must fall in the range of

0.025 to 0.125 mm (0.001 to 0.005 inches).

17. The axial end play is achieved by adding or removing

end cover gaskets (360C) for SA pumps or end cover

shims (390C) between the thrust bearing end cover

(109A) and the bearing frame (228). Add

gaskets/shims if no axial end play is present.

18. Repeat steps 13 - 16. Total travel (end play) should

fall in the range of 0.025 - 0.125 mm

(.001 - .005 in.). If the measured total travel falls

outside this range, remove or add the appropriate

quantity of individual shims to obtain the proper total

travel. For SA pumps, skip steps 19 through 22.

19. Remove thrust bearing end cover (109A).

20. Press INPRO (123A) into thrust bearing end cover

(109A). Ensure expulsion port is at 6 o'clock position

and is properly seated.

21. Install O-ring (412, not shown) into groove in thrust

bearing end cover (109A) (N/A on SA pumps).

22. Lubricate O-ring (412) with a suitable lubricant.

23. Install thrust bearing end cover (109A) with O-ring

(412) over shaft (122) and into bore of bearing frame

(228). Ensure that O-ring is not damaged while

entering bore in frame.

24. Install and tighten thrust bearing end cover/ bearing

frame screws (370N) evenly to torque values shown in

Table 7.

$

CAUTION

Do not over tighten thrust bearing end cover/ bearing

frame screws.

25. Check shaft (122) for free turning. If rubbing or

excessive drag is detected, determine cause and

correct.

$

CAUTION

For runout checks, firmly support bearing frame

assembly in horizontal position, as shown in Fig. 36.

26. Check shaft (122) impeller fit runout in the following

manner:

a.

Mount dial indicator on bearing frame (228) as

shown in Fig. 44.

b.

Rotate shaft (122) through maximum arc from one

side of keyway to the other. If total indicator

reading is greater than 0.050 mm (.002 in.),

determine cause and correct.

$

CAUTION

Avoid turning shaft so that dial indicator contacts

keyway. Readings will be incorrect and damage to dial

indicator could result.

3910-1

1th IOM 5/08

47

Fig. 43

Fig. 44

6