Goulds Pumps 3910 11th ed. - IOM User Manual

Page 45

3910-1

1th IOM 5/08

45

ASSEMBLY OF STANDARD GREASE

LUBRICATED POWER END

This section covers assembly of standard grease lubricated

power end. For power ends with optional features (pure oil

mist lubrication, bearing cooling, etc.), refer to the

appropriate section.

s

!

WARNING

Pump components are heavy. Proper methods of lifting

and securing must be employed to avoid physical injury

and/or equipment damage.

NOTE: Make sure that all parts and threads are clean

and that all directions under Inspections have been

followed.

!

Leakage of process liquid may result in creating an

explosive atmosphere. Follow all pump and seal

assembly procedures.

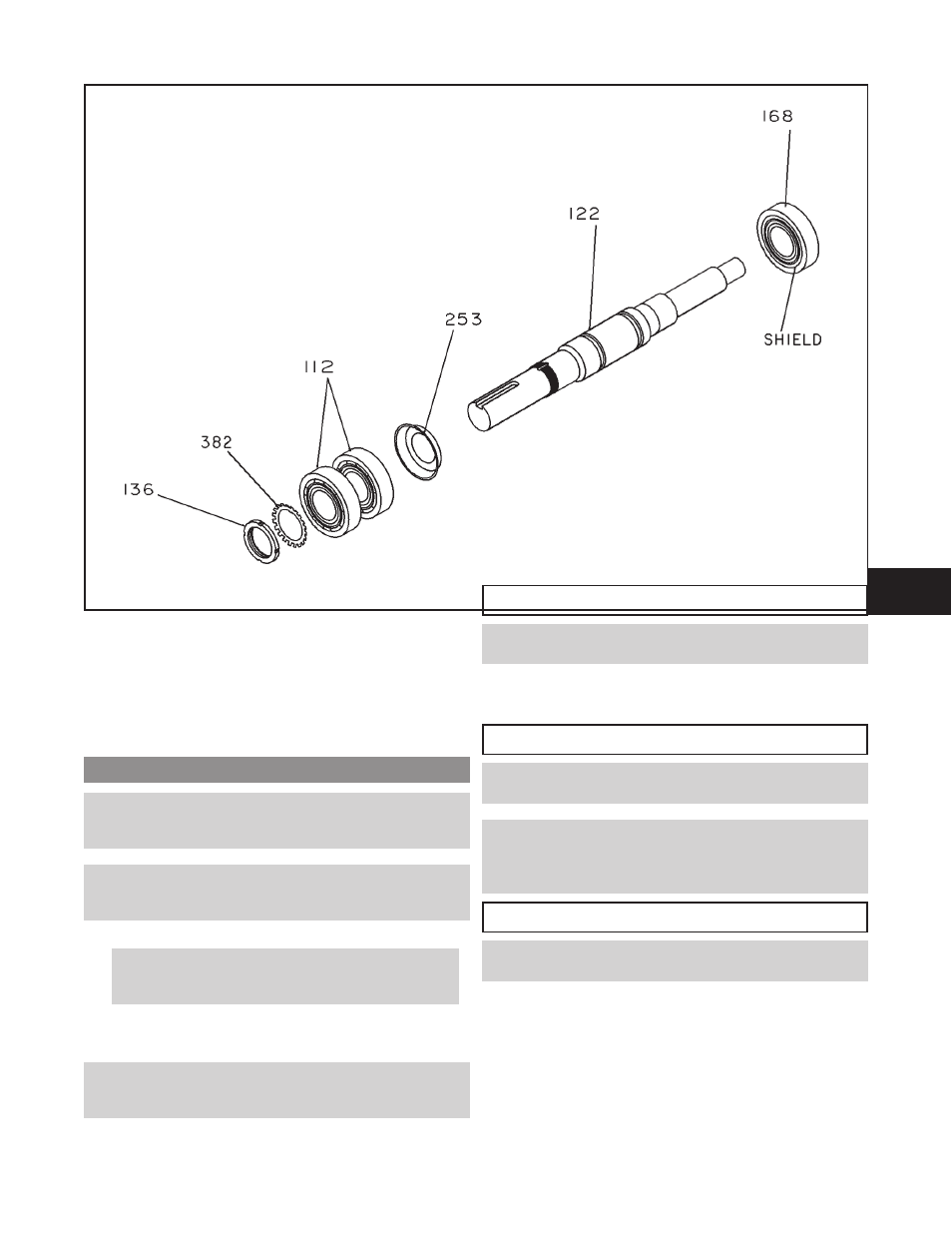

1.

Install radial (inboard) bearing (168) on shaft (122)

with shield facing shaft shoulder (Fig. 38).

NOTE: There are several methods used to install bear-

ings. The recommended method is to use an induction

heater that heats as well as demagnetizes the bearings.

$

CAUTION

Use insulated gloves when using a bearing heater.

Bearing will get hot and can cause physical injury.

2.

Install grease shelf (253) on shaft (122).

3.

Install thrust (outboard) bearings (112) on shaft (122).

$

CAUTION

The Model 3910 uses duplex bearings mounted back-to-

back. Make sure orientation of the bearings is correct.

NOTE: There are several methods used to install

bearings. The recommended method is to use an

induction heater that heats as well as demagnetizes the

bearings.

$

!

CAUTION

Use insulated gloves when using a bearing heater.

Bearings will get hot and can cause physical injury.

4.

Place bearing lockwasher (382) on shaft (122). Place

tang of lockwasher in keyway of shaft.

5.

Thread bearing locknut (136) onto shaft (122). After

bearings and shaft have cooled to ambient temperature,

tighten locknut to torque value shown in Table 7.

6.

Bend any tang of bearing lockwasher (382) into a slot of

locknut (136).

Fig. 38

6