Caution – Goulds Pumps 3910 11th ed. - IOM User Manual

Page 46

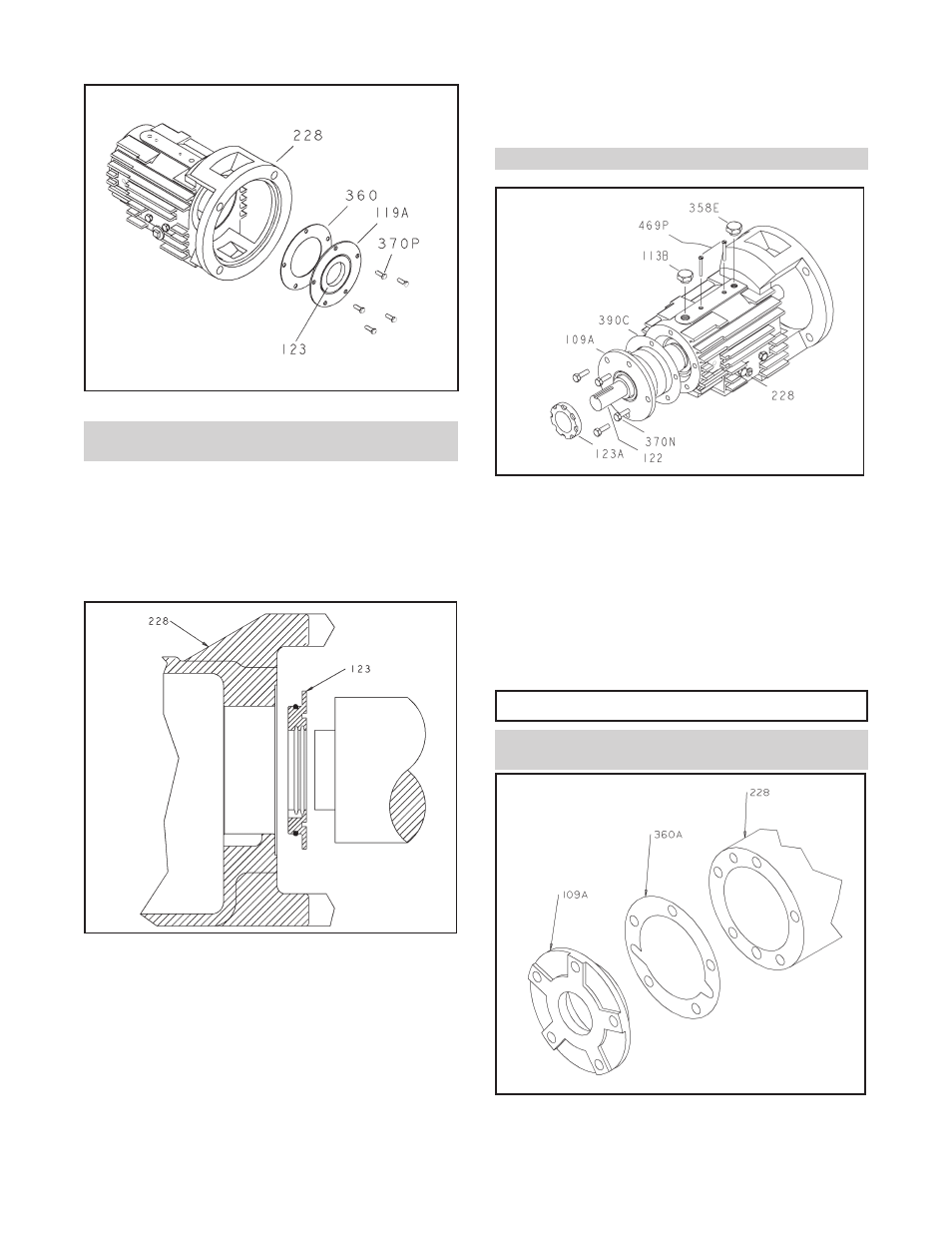

NOTE: Coat internal surfaces of bearings with

lubricant to be used in service.

7.

Press radial INPRO (123) into radial end cover (119A).

Ensure expulsion port is at 6 o'clock position and is

properly seated. Install radial bearing end cover (119A),

and new end cover gasket (360) on bearing frame (228)

(Fig. 39). For SA pumps, press radial INPRO (123) into

bearing frame 228. Ensure expulsion port is at 6 o'clock

position and is properly seated (Fig. 40).

8.

For SX, MX, LA, and XLX pumps, install and tighten

radial end cover bolt/bearing frame screws (370P)

evenly to the torque values shown in Table 7.

9.

Coat outer races of bearings (112) and (168) with

compatible oil.

10. Coat internal bearing surfaces of bearing frame (228)

with compatible oil.

11. Carefully guide shaft/bearing assembly into bearing

frame (228) until thrust bearing (112) is seated against

shoulder of frame (Fig. 41).

NOTE: Do not force assembly together.

12. Check shaft (122) for free turning. If rubbing or

binding is detected, determine cause and correct.

13. For SX, MX, LA, and XLX pumps, install three (3)

thrust bearing end cover shims (390C) on the thrust

bearing end cover (109A) and align holes. For SA

pumps, install three (3) thrust bearing end cover

gaskets (360A) on the bearing end cover (109A).

Align the gasket to the end cover so that the openings

in the gaskets align with the oil grooves on the end

cover (Fig. 42).

$

!

CAUTION

Failure to align gasket with oil grooves will result in

bearing failure from lack of lubrication.

46

3910-1

1th IOM 5/08

Fig. 39

Fig. 40

Fig. 41

Fig. 42