Goulds Pumps 3910 11th ed. - IOM User Manual

Page 40

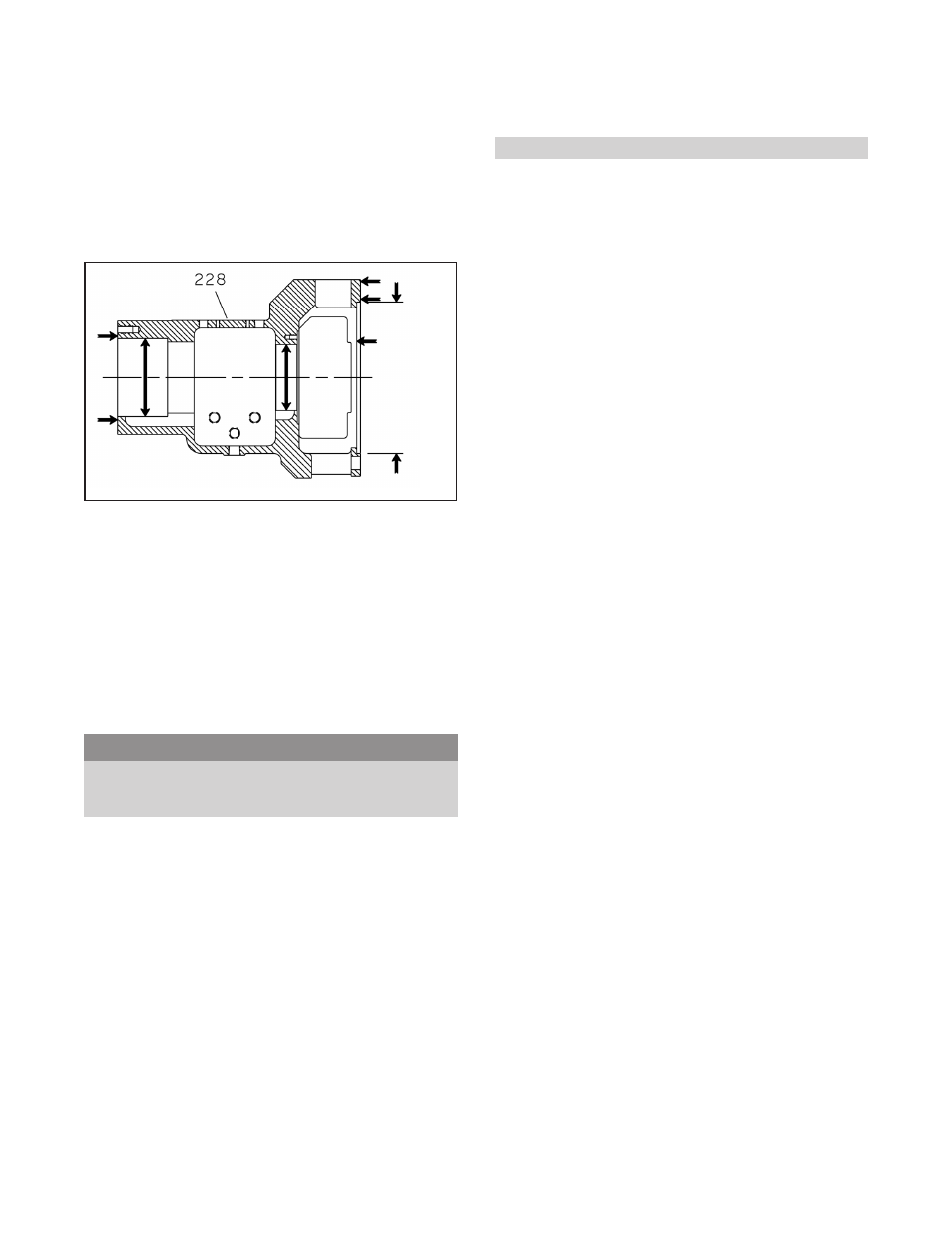

BEARING FRAME (228)

1. Visually inspect bearing frame for damage and cracks.

2. Check frame inside surfaces for rust, scale or debris.

Remove all loose and foreign material (Fig. 29).

3. Make sure all lubrication passages are clear.

4. Check bearing bores. If any are outside the tolerance

in Table 6, replace the bearing frame.

CARTRIDGE MECHANICAL SEAL

Refer to mechanial seal manufacturer’s instructions for

assistance.

Cartridge type mechanical seals should be serviced by seal

manufacturer.

COUPLING GUARD

1. Inspect guard for corrosion or other defects.

2. Replace guard or repair.

s

!

WARNING

To avoid physical injury, coupling guard must be

installed and must be maintained in first-class

condition.

GASKETS, O-RINGS, SHIMS, AND

SEATS

NOTE: Spiral wound gaskets should not be reused.

1. Replace all gaskets, O-rings and shims at each

overhaul / disassembly.

2. Inspect seats. They must be smooth and free of

physical defects. Skin cut seats in lathe as necessary,

maintaining dimensional relationships with other

surfaces. Replace parts if seats are defective beyond

reasonable repair.

GENERAL

All other parts should be inspected and repaired or

replaced, as appropriate, if inspection indicates continued

use would be harmful to satisfactory and safe pump

operation.

Inspection must include, but not be limited to, the

following:

•

Bearing End Covers (109A) and (119A)

•

INPROS (123) and (123A)

•

Radial Heat Flinger (123B)*

•

Thrust Fan (123E)*

•

Bearing Locknut (136)

•

Impeller Key (178) and Coupling Key

•

Impeller Nut (304)

•

Bearing Lockwasher (382)

•

Water Jacket Cover (490)*

•

All Nuts, Bolts and Screws

* If supplied.

40

3910-1

1th IOM 5/08

Fig. 29