Goulds Pumps 3420 - IOM User Manual

Page 76

d. Check the clearance by rotating the shaft 90

° and

measuring the clearance. Tighten the locknut, if

required. This should be done several times to ensure

the bearing is not distorted.

7.

Bend a tang of the lockwasher into a locknut groove.

8.

Oil Lubrication

a. Bolt the oil ring housings (515 and 515A) to the

bearing housings (134 and 134A) using capscrews (371T).

b. Place the oil rings (114) in the grooves on the oil

ring sleeve.

c. Bolt the end covers (109A) and 119A) to the

bearing housings using capscrews (371S). Tighten

finger tight.

d. Slide the dust cover (139) and the coupling on the shaft.

Grease Lubrication: Slide the dust cover (123A) with

the seal installed and the coupling on the shaft.

D. LDS and XL Group

1.

Oil Lubrication

*a. Slide the oil throwers (123) on the shaft (122).

b. Install the bearing end covers (109B and 119B) on

the bearing housings (134 and 134A) with capscrews

(370). Tighten the capscrews to the torque value

shown in Table 11.

c. Slide the bearing housing sub-assemblies on the shaft.

Grease Lubrication

*a. Slide the deflectors (333) on the shaft (122).

*b. Install the grease seals (333) in the inboard

bearing end covers (109B and 119B).

c. Install the bearing end covers on the bearing

housings (134 and 134A) with capscrews (370).

Tighten the capscrews to the torque value shown in

Table 11.

d. Slide the bearing housing sub-assemblies on the

shaft.

2.

Slide the roller bearings (409 and 410) on the shaft

until they contact the shaft shoulder.

NOTE: The inner race of the roller bearing has a

tapered bore. Make sure the large bore end of the

bearing faces the end of the shaft. The lip of the adapter

sleeve slides under the inner race of the bearing.

3.

Lightly oil the shaft and the outside diameter of the

adapter sleeve. Slide the lip of the sleeve under the

inner race of the bearing.

4.

Slide the oil ring sleeves (324) on the shaft.

5.

Place the bearing lockwashers (382) and the bearing

locknuts (136) on the shaft and tighten finger tight.

6.

L, LDS, XL, and XXL frames use spherical roller

bearings mounted on tapered sleeves which require

tightening of the bearing locknut to draw the bearing

up on the taper. Correct tightening of the locknut is

accomplished by measuring the clearance before and

after tightening to arrive at a given change in bearing

clearnace. Once this change in clearance has been

reached, the bearing is correctly mounted on the

sleeve. The minumum clearance after tightening

should also not be less than the given value. The

following steps describe how this is accomplished:

a.

With the bearing axis horizontal and no upward force

on the bearing outer race, rotate the inner race such

that a set of rollers is at the bottom. Measure the

clearance between the bottom roller OD and the ID of

the bearing outer race using a feeler gauge. Record

this value.

b.

Tighten the locknut (136) until a reduction

(measurement from Step 6a minus the measurement

after tightening of the locknut) in bearing clearance is

reached as given below. Also, verify the minimum

clearance is not less than the value given below.

Rotate the bearing through 90 degree increments and

verify the clearance in a few positions.

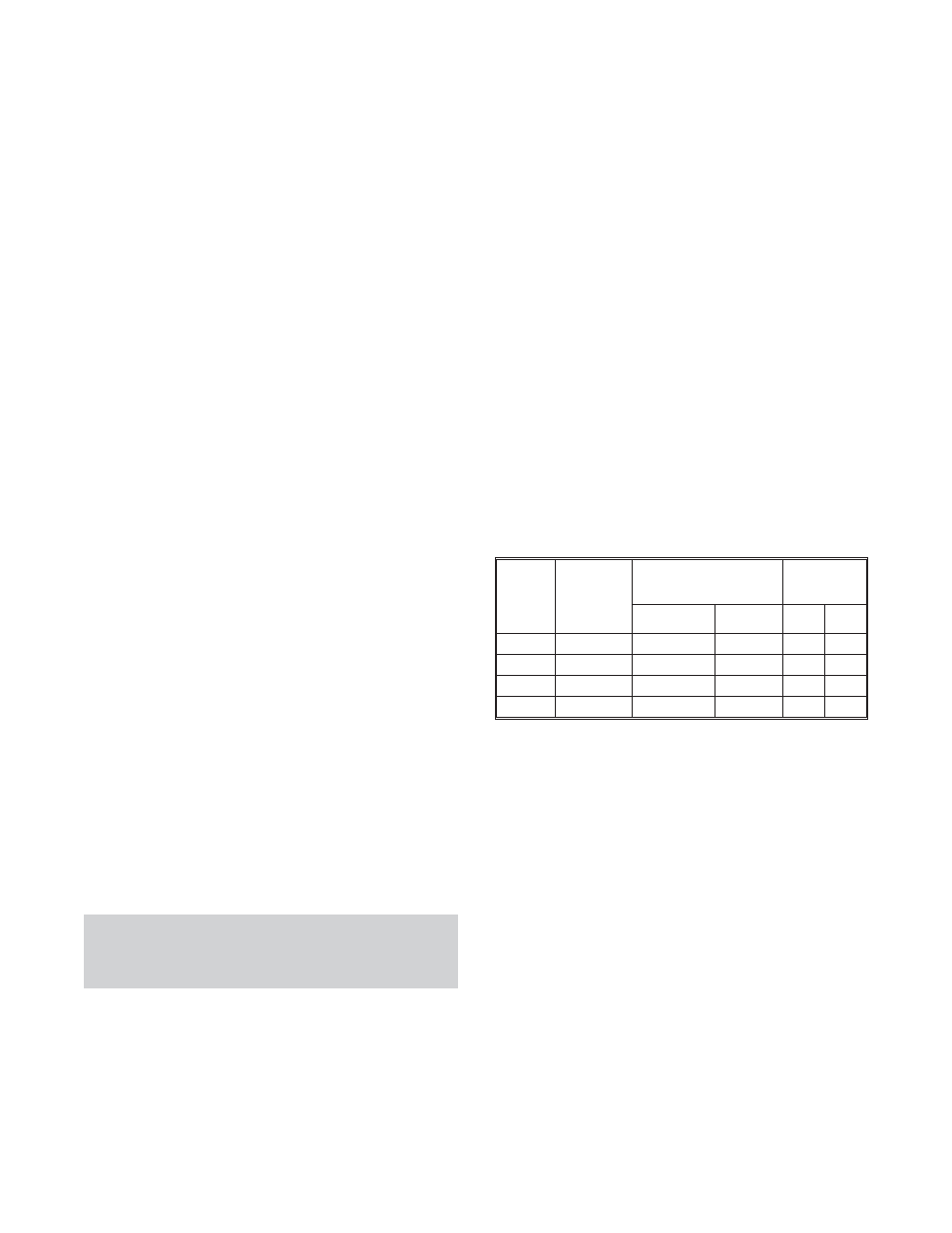

Group

SKF

Bearing

Size

Clearance

Reduction

Minimum

Clearance

Inches

mm

In.

mm

L

22226 CN

.0025-.0035

.065-.09

.002

.055

LDS

22228 CN

.0025-.0035

.065-.09

.002

.055

XL

22230 CN

.003-.004

.075-.10

.0022

.06

XXL

22240 CN

.0032-.0043

.08-.11

.0024

.06

7.

Bend a tang of the lockwasher into a locknut groove.

8.

Oil Lubrication

a. Bolt the bearing housings (134 and 134A or 134D

and 134A) to the bearing end covers (109A and 119B)

using capscrews (370 or 371C). Tighten the

capscrews to the torque shown in Table 11.

b. Place the oil rings (114) in the grooves on the oil

ring sleeve.

c. Bolt the end covers (109A and 119A) to the

bearing housings using capscrews (370 or 371C).

Tighten finger tight.

*d. Slide the dust cover (123A) and the coupling on

the shaft.

*

These parts are replaced by the optional labyrinth

seals (332 Opt), 333 Opt) when so equipped. Do not

separate the rotor from the stator with labyrinth style

seals.

72

3420 IOM 8/09