Caution – Goulds Pumps 3420 - IOM User Manual

Page 32

4.

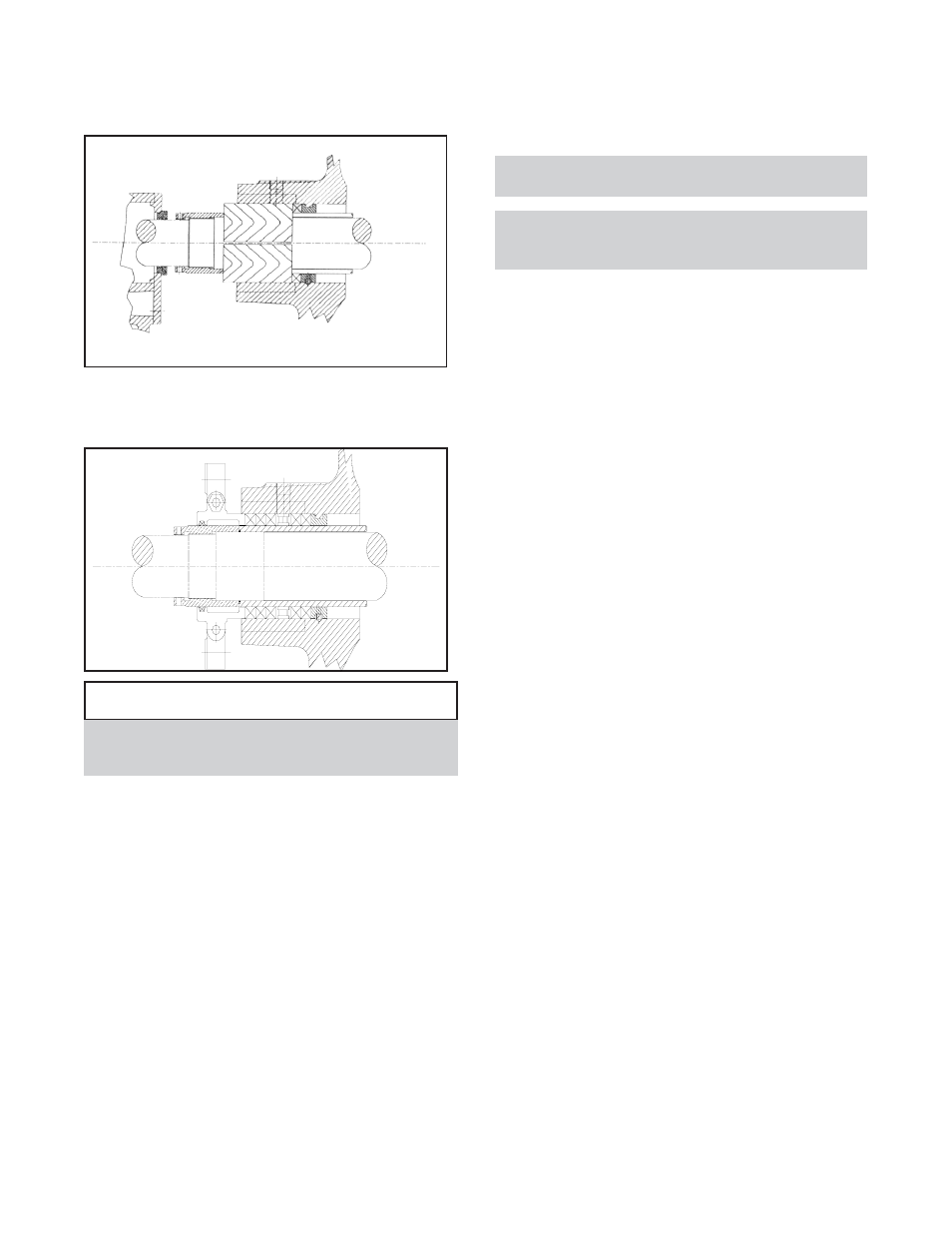

Use a wooden split bushing to properly seat the first

two rings of packing. See Fig 16.

5.

The stuffing box arrangement in order of installation

is: two packing rings, lantern ring, then three packing

rings. See Fig. 17.

$

CAUTION

Follow instructions to ensure the lantern ring is

located at the flushing connection. Otherwise, no

flush will be obtained.

6.

Install the gland halves. Bolt the gland halves together

and mount on gland studs. Tighten gland nuts.

Connection of Sealing Liquid: If the stuffing box pressure

is above atmospheric pressure and the pumpage is clean,

normal gland leakage of 40-60 drops per minute is usually

sufficient to lubricate and cool the packing. Sealing liquid

then, is not required.

An external sealing liquid is required when:

1.

Abrasive particles in the pumpage could score the

shaft sleeve.

2.

Stuffing box pressure is below atmospheric pressure

due to the pump running with suction lift or when the

suction source is under a vacuum. Under these

conditions, packing will not be cooled and lubricated

and air will be drawn into the pump.

If an outside source of clean compatible liquid is required,

the pressure should be 15 psi (1.0 kg/cm

2

) above the suction

pressure for clean pumpages. For an abrasive pumpage, the

flush water pressure should be 30-50 psi (2.1-3.5 kg/cm

2

)

above the suction pressure.

NOTE: A product flush can be used if a clean

pumpage exists.

NOTE: Most packing requires lubrication. Failure to

lubricate the packing may shorten the life of the

packing and the pump.

28

3420 IOM 8/09

Fig. 17

Fig. 16