Goulds Pumps 3420 - IOM User Manual

Page 30

2.

Install the coupling guard (Fig. 13). Refer to the

Coupling Guard Installation and Disassembly Section

(Appendix I).

!

The coupling guard used in an ATEX classified

environment must be constructed from a

non-sparking material.

s

!

WARNING

Never operate a pump without the coupling guard

installed. Personal injury will occur if the pump is run

without the coupling guard.

!

Cooling systems such as those for bearing

lubrication, mechanical seal systems, etc, where

provided, must be operating properly to prevent

excess heat generation, sparks and premature

failure.

!

Rotate shaft by hand to ensure it rotates smoothly

and there is no rubbing which could lead to excess

heat generation and or sparks.

!

Ensure that pump and systems are free of foreign

objects before operating and that objects cannot

enter the pump during operation. Foreign objects in

the pumpage or piping system can cause blockage of

flow which can result in excess heat generation,

sparks and premature failure.

!

Do not insulate bearing housings as this can result

in excess heat generation, sparks and premature

failure.

!

Check for magnetism on the pump shaft and

degauss the shaft if there is any detectable

magnetism. Magnetism will attract ferritic objects to

the impeller, seal and bearings which can result in

excess heat generation, sparks and premature

failure.

!

Leakage of process liquid may result in creating an

explosive atmosphere. Ensure the materials of the

pump casing, impeller, shaft, sleeves, gaskets and

seals are compatible with the process liquid.

!

A build up of gases within the pump, sealing system

and or process piping system may result in an

explosive environment within the pump or process

piping system. Ensure process piping system, pump

and sealing system are properly vented prior to

operation.

LUBRICATING BEARINGS

!

Bearings must be lubricated properly in order to

prevent excess heat generation, sparks and

premature failure.

$

CAUTION

Pumps are shipped without oil.

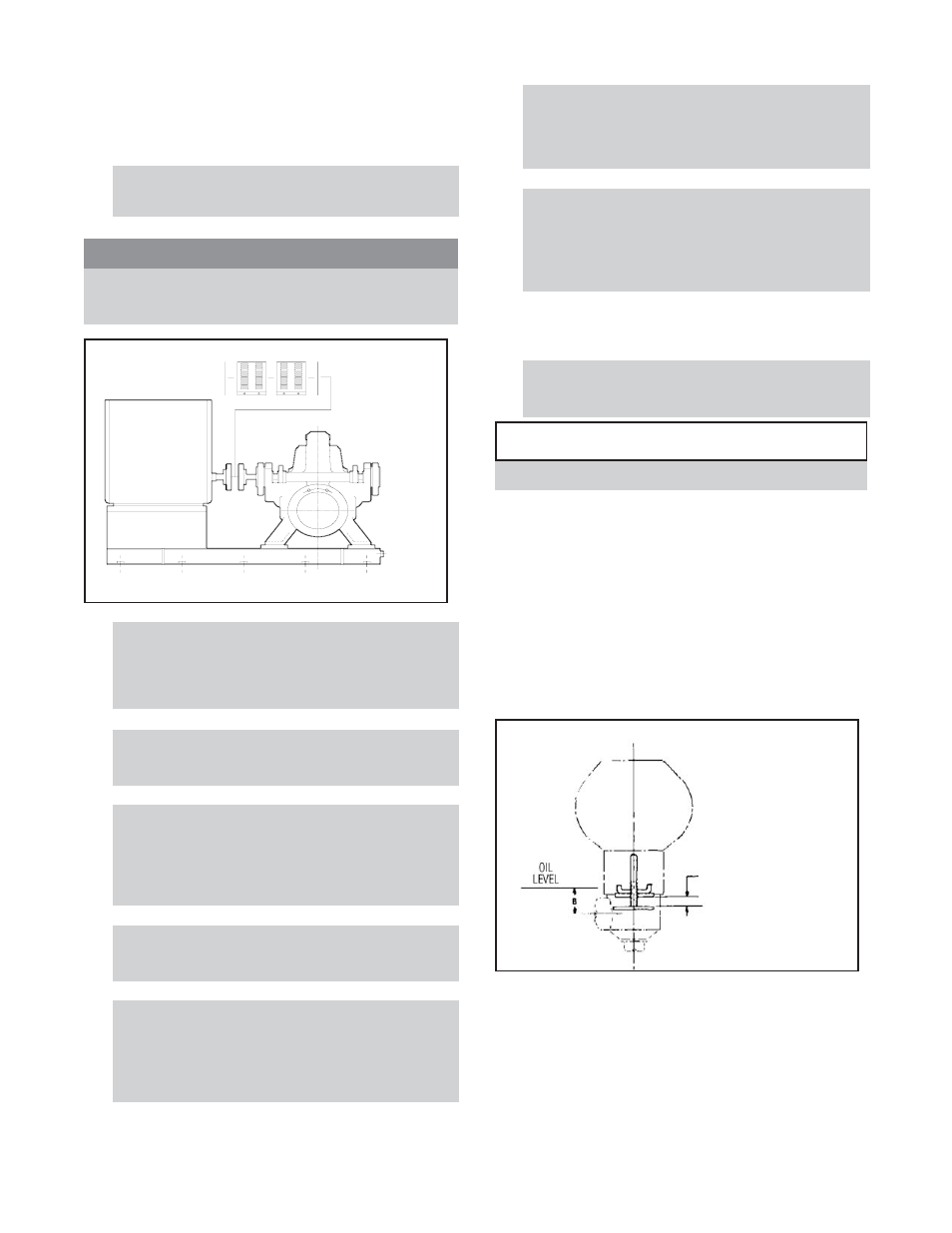

Oil Lubrication: Oil lubricated pumps are not lubricated at

the factory. Constant level oilers are supplied with oil

lubricated pumps. The oiler can be found in the box of

fittings that accompanied the pump during shipment. The

oiler was adjusted to maintain the proper oil level before

leaving the factory. The adjustment should be checked in

case the setting was disturbed during shipment. See Figure

14. The correct dimensions for A and B are given in Table

2. Fill the bearing housing with oil using the oil bottle.

Continue to refill the oil bottle until oil stops draining from

the oiler into the housing. See Table 4 for recommended

oil.

Pure/Purge Oil Mist: For pure oil mist, connect the oil

mist system according to the manufacturer's

recommendations. For purge oil mist, connect the oil mist

system per the manufacturers instructions. Fill the pump

with oil as detailed for oil lubrication above. In both cases,

refer to the pump dimensional drawing for the location of

the oil mist connections to the bearing housings. See Table

2 for oil bottle settings and Table 4 for recommended oil.

26

3420 IOM 8/09

Fig. 13

Instructions

1. Remove adjustment

assembly from oiler.

2. Adjust bars to dim. "A".

3. Lock in position.

4. Replace adjust. assem. in

oiler

A

Fig. 14