Maintenance of bearings, Three month inspections, Annual inspections – Goulds Pumps 3420 - IOM User Manual

Page 38: Oil lubricated bearings, Warning, Caution

THREE MONTH INSPECTIONS

•

Check foundation and hold-down bolts for tightness.

•

If the pump has been left idle, check the packing.

Replace, if required.

•

Oil should be changed every three months (2,000 hrs)

or more often if there are any adverse atmospheric

conditions or other conditions that may contaminate

or break-down the oil. Change the oil whenever it

appears cloudy or contaminated.

•

Check the shaft alignment. Re-align if required.

ANNUAL INSPECTIONS

•

Check the pump capacity, pressure, and power. If the

pump performance does not satisfy your process

requirements and your process requirements have not

changed, the pump should be disassembled,

inspected, and the worn parts replaced. Otherwise, a

system inspection should be done.

MAINTENANCE OF BEARINGS

!

Bearings must be lubricated properly in order to

prevent excess heat generation, sparks and

premature failure.

OIL LUBRICATED BEARINGS

s

!

WARNING

Pumps are shipped without oil. Oil lubricated bearings

must be lubricated at the jobsite.

Change the oil after 200 hours for new bearings.

Thereafter, change the oil every 2,000 hours or three

months, whichever comes first.

Ring oil or flood oil lubricated anti-friction bearings are

standard on all model 3420 pumps. Oil lubricated pumps

are supplied with oilers which maintain a constant oil level

in the bearing housings. Each oiler should be installed and

the pump lubricated as follows:

1.

Check the oiler adjustment prior to installing the oiler,

refer to Table 2 for the proper oiler setting.

2.

Install one oiler in each bearing housing.

$

!

CAUTION

Do not fill the bearing housings with oil through any

connection other than the oiler connection. This can

result in an improper oil level which may shorten the

life of the bearings and cause damage to the pump.

34

3420 IOM 8/09

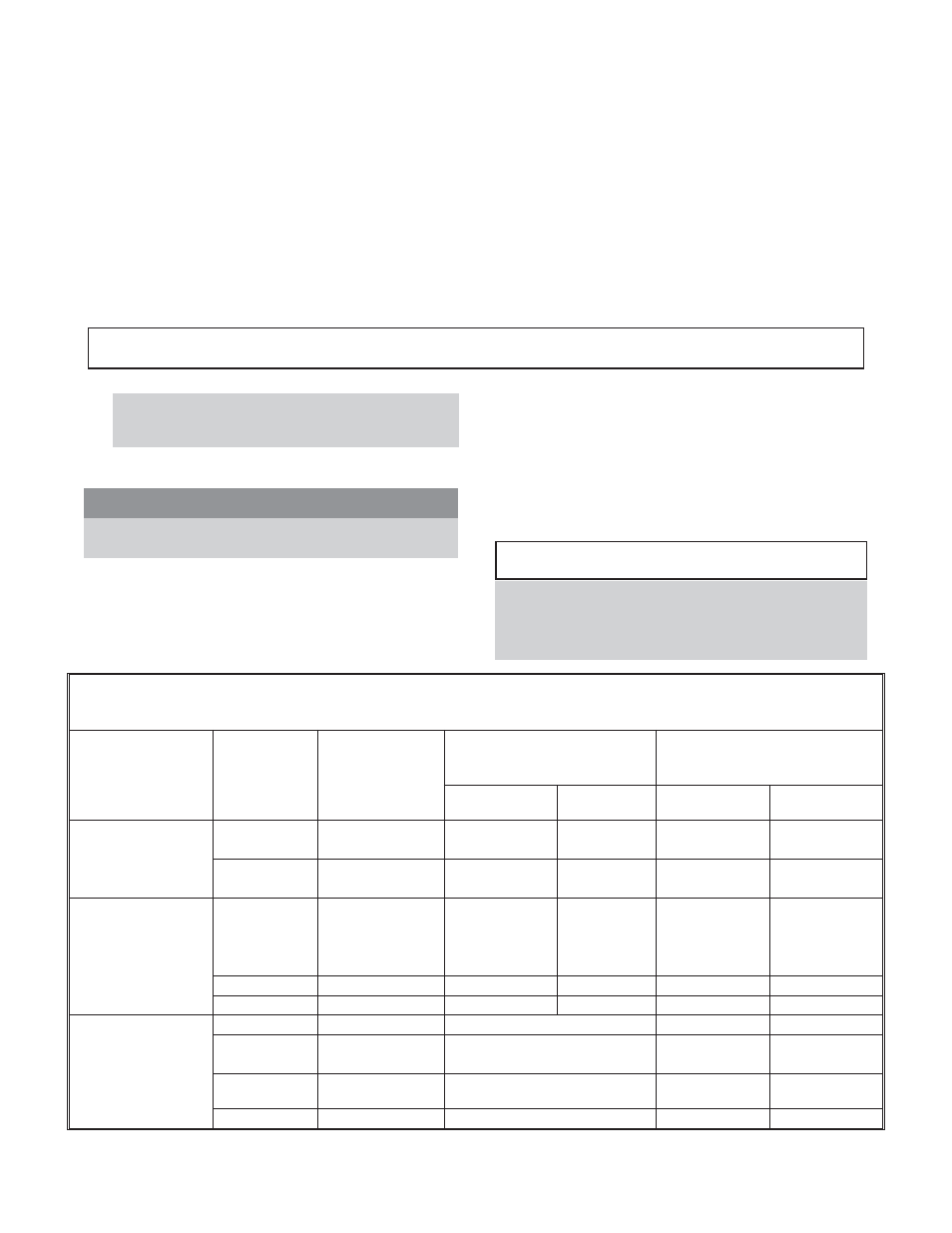

Table 3

Bearings and Oil Requirements

Bearing

Arrangement

Group

Sizes

Bearing Size

Oil Volume Required

(per each housing)

Thrust

Radial

mL

pints

Flood Oil Ball Bearing

SX

12 x 14-15

7313

6313

thrust = 850

thrust = 1.80

16 x 18-17H

radial = 580

radial = 1.23

MX

18 x 20-20

7316

6316

thrust = 1350

thrust = 2.85

radial 857

radial = 1.81

Ring Oil Ball Bearing

M

16 x 18-30

7321

6321

1170

2.47

18 x 20-30

20 x 24-24

20 x 24-30

M (modified)

20 x 24-28

7321

6321

1350

2.85

-

18 x 20-24

7318

6318

620

1.32

Ring Oil Roller Bearing

L

24 x 30-32

22226

1700

3.60

LDS

30 x 30-31

22228

1720

3.64

30 x 30-38

XL

30 x 36-42

20x30-42

22230

1350

2.85

XXL

36x42-52

22240

4350

9.2