Starting pump, Operation – Goulds Pumps 3420 - IOM User Manual

Page 35

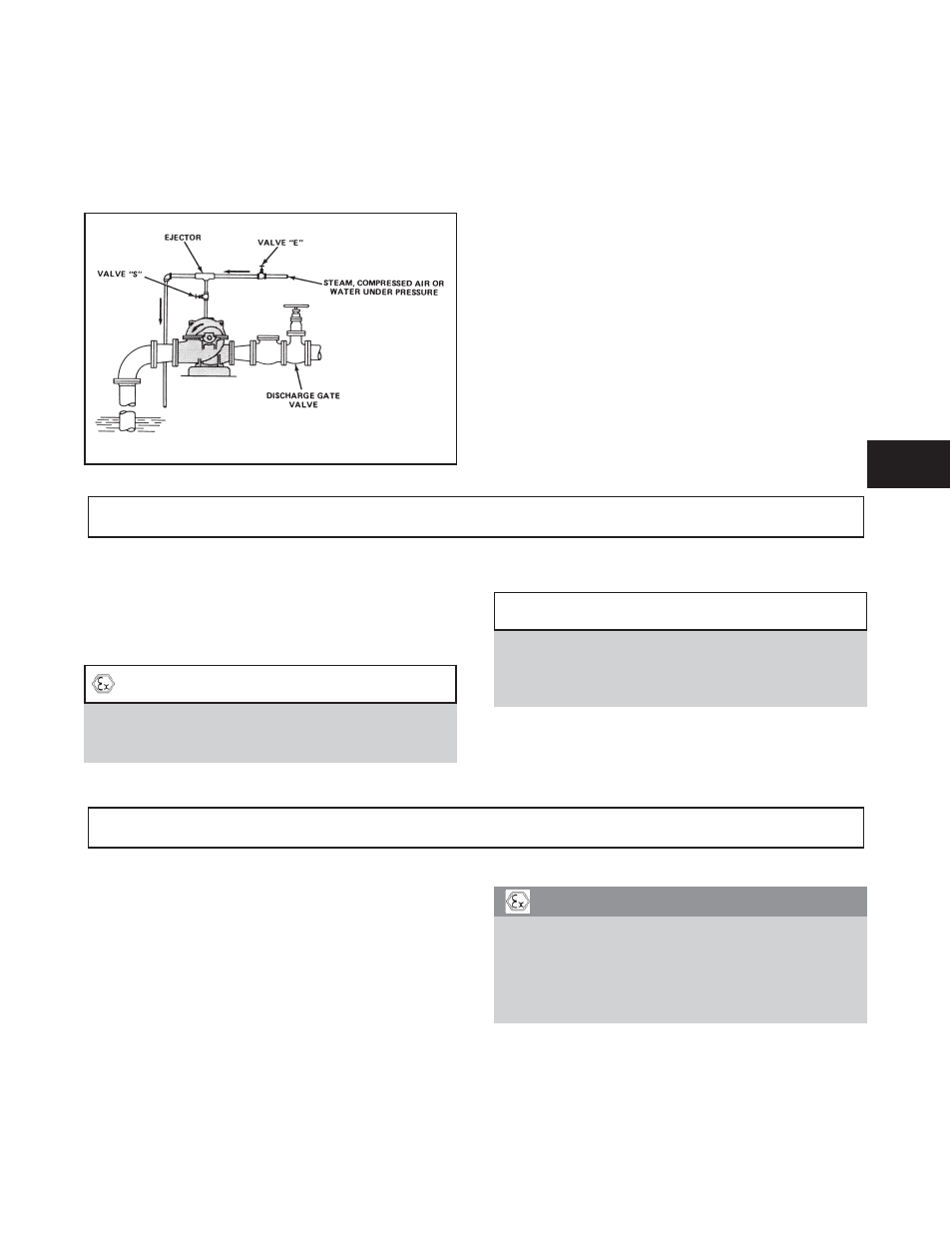

Priming with an Ejector (Fig. 22)

On suction lift applications, an ejector (operated by steam,

compressed air, or pressurized water) connected to the top

of the casing (priming or vent connection) can be used to

remove air from the casing and suction line, thus priming

the pump.

1.

Close the discharge valve.

2.

Open the ejector supply valve in the steam, air, or

water line, valve “E”.

3.

Open the priming isolation valve, “S”.

4.

Once the unit is primed, close the priming isolation

valve, “S”.

5.

Close the ejector supply valve, “E”.

6.

Start the pump and open the discharge valve.

STARTING PUMP

1.

Make sure the suction valve and any recirculation or

cooling lines are open.

2.

Fully close or partially open the discharge valve as

dictated by system conditions.

3.

Start the driver.

$

CAUTION

Immediately observe the pressure gauges. If the

discharge pressure is not quickly attained, stop the

driver, reprime, and attempt to restart.

4.

Slowly open the discharge valve until the desired flow

is obtained.

$

CAUTION

Observe the pump for vibration levels, bearing

temperature, and excessive noise. If normal levels are

exceeded, shut down the pump and troubleshoot the

problem.

OPERATION

GENERAL CONSIDERATIONS

Always vary the capacity by regulating the discharge valve.

NEVER throttle the flow from the suction side.

The driver may overload if the pumpage specific gravity

(fluid density) is greater than originally stated or if the flow

rate is exceeded.

Always operate the pump at or near the rated conditions to

prevent damage resulting from cavitation or recirculation.

OPERATING AT REDUCED CAPACITY

s

!

WARNING

DO NOT operate the pump below the minimum rated

flow or with the suction and/or discharge valves closed.

These conditions may create an explosive hazard due to

vaporization of the pumpage. This can quickly lead to

pump failure and physical injury. Refer to Appendix II

for the pump's minimum flow.

Damage occurs from:

1.

Increased vibration levels - This affects the bearings,

stuffing box, and mechanical seal (if supplied).

3420 IOM 8/09

31

4

Fig. 22