Bearing removal – Goulds Pumps 3420 - IOM User Manual

Page 40

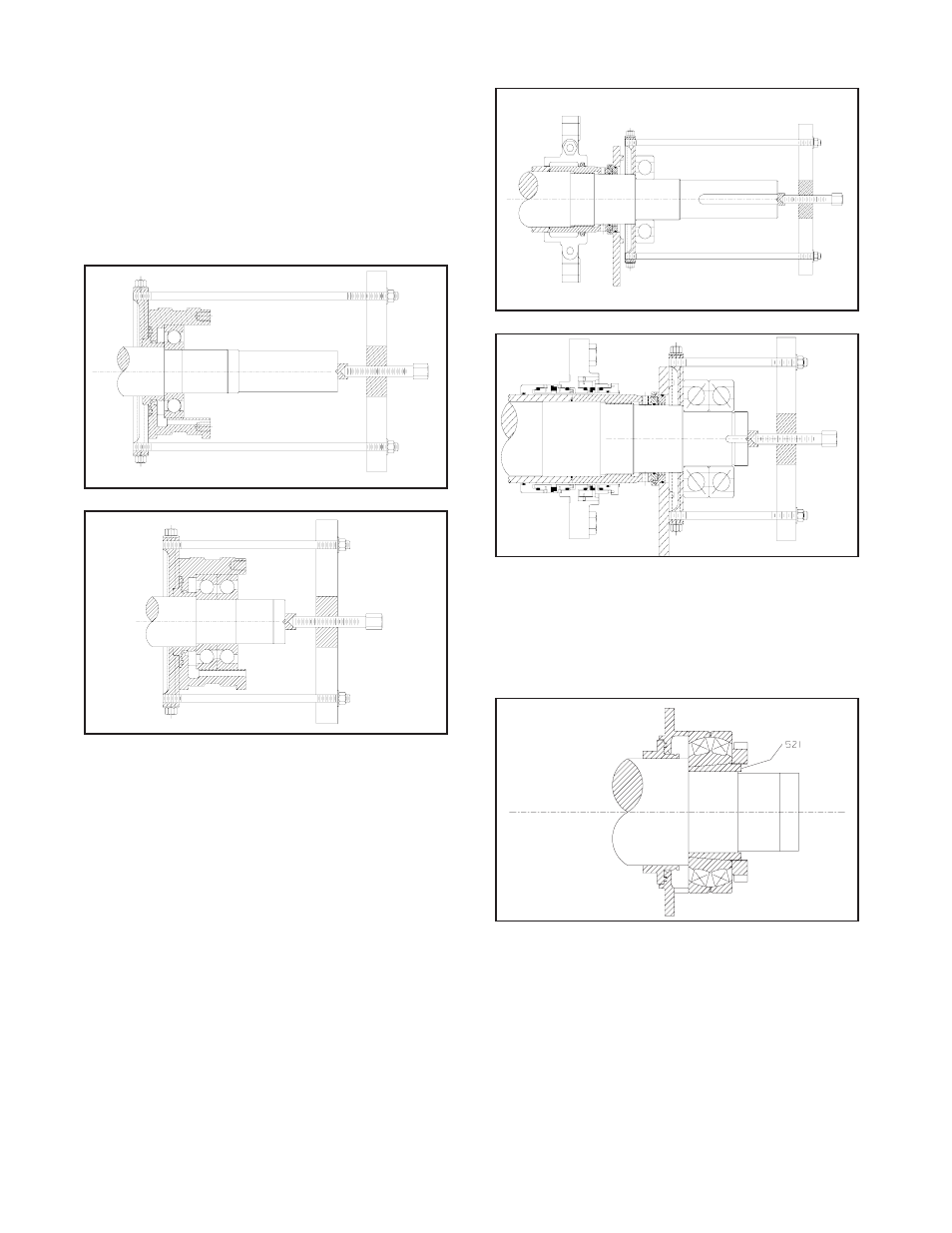

BEARING REMOVAL

Ball Bearings

A puller, such as the one shown in Figures 23 and 24,

should be used. The puller bar must be square with the end

of the shaft at all times in order to keep even pressure on

the outer circumference of the bearing. The puller screw

should be tightened steadily to enable the bearing to slide

smoothly off the shaft. Do not damage the end of the shaft.

On the SX/MX units, the bearing housings slide off the

bearings and the puller, such as the one shown in Figures

25 and 26, should be used. This type of puller applies force

directly against the bearing itself. The puller bar must be

square with the end of the shaft at all times and the puller

screw should be tightened steadily to enable the bearings to

slide smoothly off the shaft. Do not damage the end of the

shaft.

Roller Bearings

1.

Screw the adapter sleeve removal nut (furnished in the

box of fittings which accompanied the pump) onto the

adapter sleeves (item 521). Tightening the nut will

"jack" the sleeves out from under the inner race of the

bearings.

2.

Slide the adapter sleeves and bearings off of the shaft

and protect them from contamination. Unscrew the

adapter removal nut and store it for future use.

36

3420 IOM 8/09

Fig. 25

Fig. 26

Fig. 24

Fig. 23

Fig. 27