Impeller-clearance setting – Goulds Pumps 3198 i-FRAME - IOM User Manual

Page 45

Impeller-clearance setting

Importance of a proper impeller clearance

A proper impeller clearance ensures that the pump runs at high performance.

WARNING:

• The impeller clearance setting procedure must be followed. Improperly setting the clearance or not

following any of the proper procedures can result in sparks, unexpected heat generation, and

equipment damage.

• If you use a cartridge mechanical seal, you must install the centering clips and loosen the set screws

before you set the impeller clearance. Failure to do so could result in sparks, heat generation, and

mechanical seal damage.

Impeller clearance methods

You can set the impeller clearance with either of these methods:

• Dial indicator method

• Feeler gauge method

Set the impeller clearance - dial indicator method (all except CV 3196)

WARNING:

Always disconnect and lock out power to the driver before you perform any installation or maintenance

tasks. Failure to disconnect and lock out driver power will result in serious physical injury.

1. Remove the coupling guard.

2. Set the indicator so that the button contacts either the shaft end or the face of the coupling.

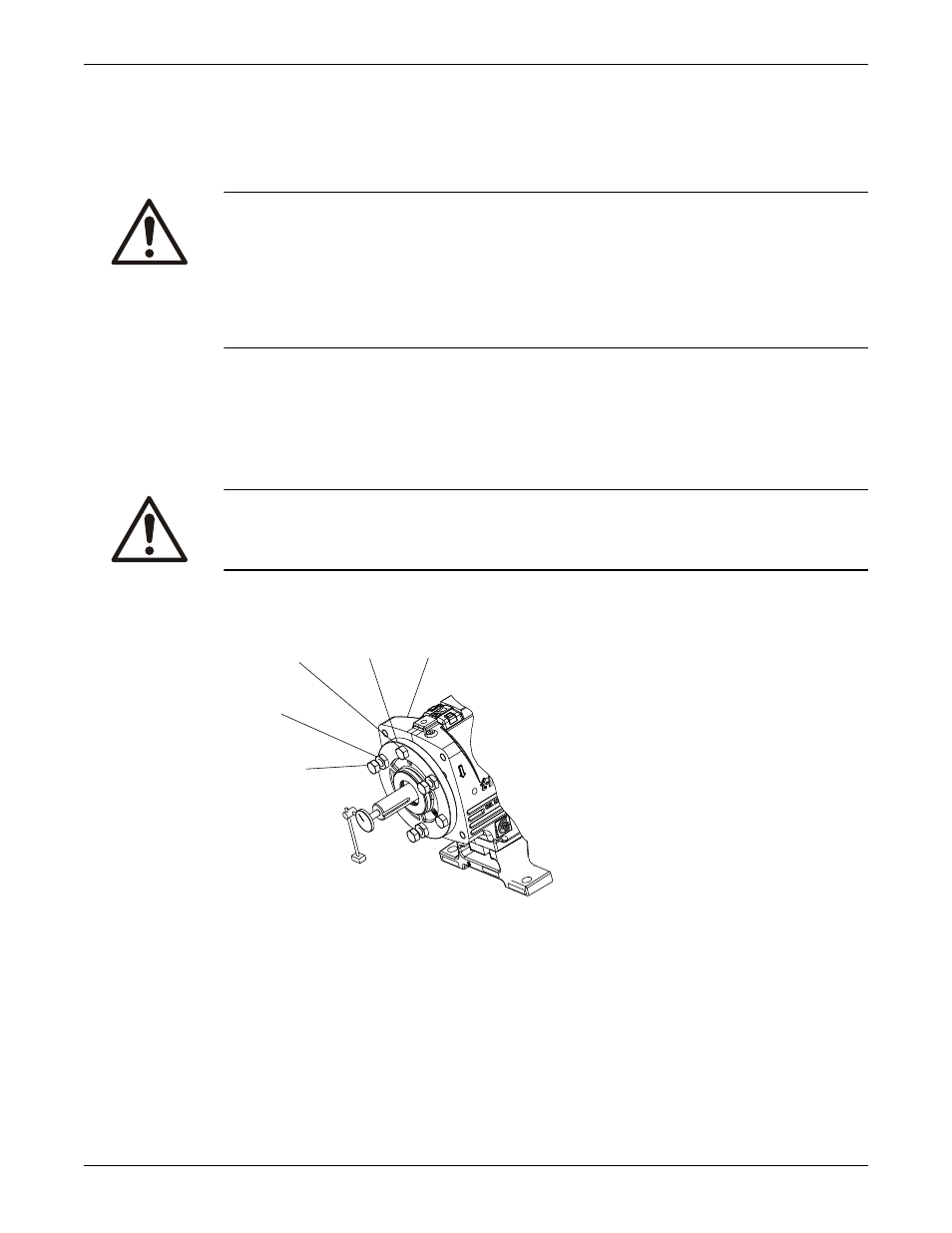

228

134A

423

370C

370D

3. Loosen the jam nuts (423) on the jack bolts (370D) , and then back the bolts out about two turns.

4. Tighten the locking bolts evenly (370C), bringing the bearing housing (134A) towards the frame (228)

until the impeller contacts the casing.

5. Turn the shaft to ensure that there is contact between the impeller and the casing.

6. Set the indicator to zero and loosen the locking bolt (370C) about one turn.

7. Thread in the jack bolts (370D) until the jack bolts evenly contact the bearing frame.

8. Tighten the jack bolts evenly about one flat at a time, moving the bearing housing (134A) away from

the bearing frame until the indicator shows the correct clearance.

Commissioning, Startup, Operation, and Shutdown

Model 3198 i-FRAME Installation, Operation, and Maintenance Manual

43