Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 94

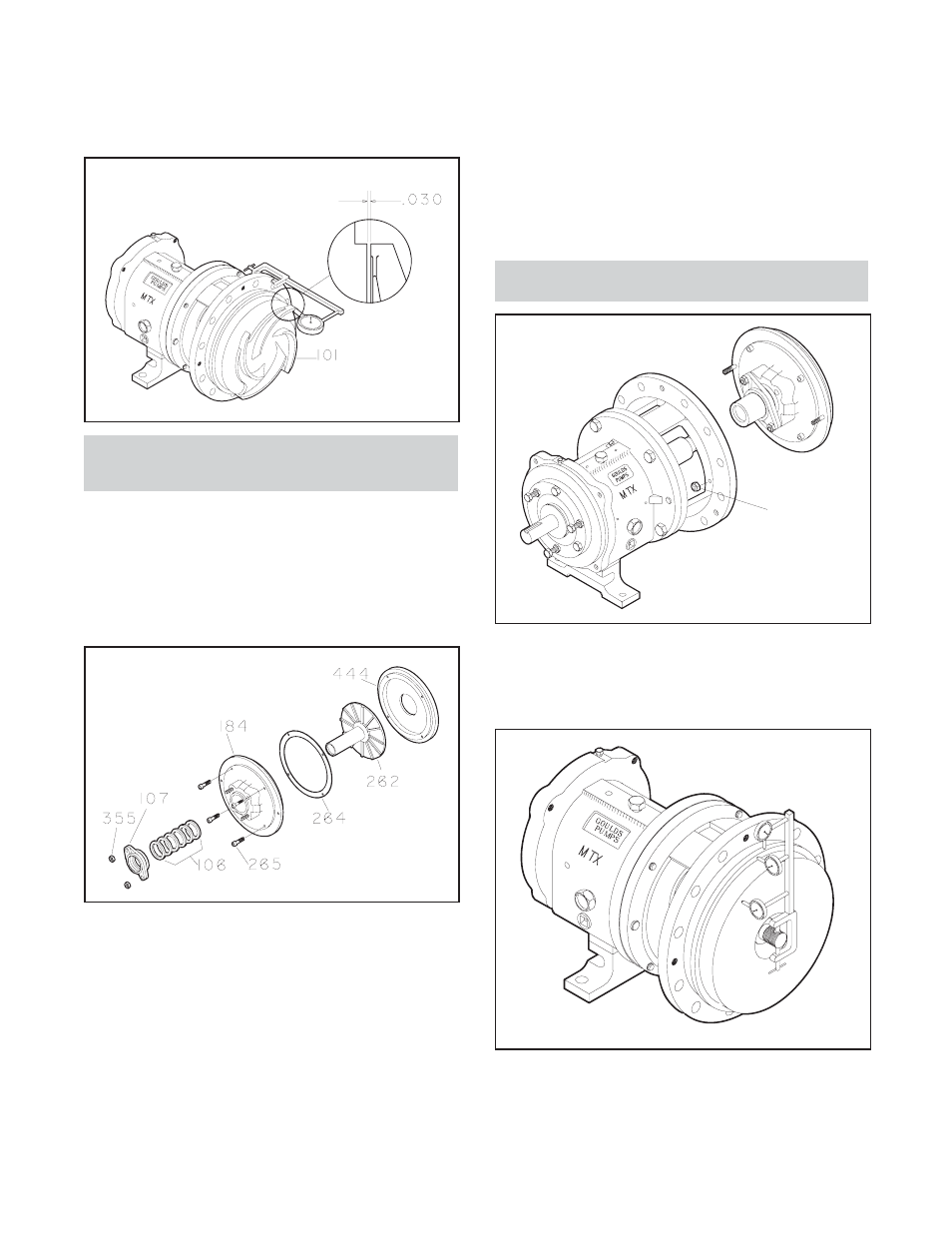

6.

Check impeller runout. Check vane tip to vane tip.

Total indicator reading greater than 0.005 in.

(.13 mm) indicates a problem (Fig. 170).

NOTE: The face of the CV 3196 impeller is not

machined. Checking the face runout on the

CV 3196 impeller is not required.

7.

Install packing and gland according to Section 4,

Operation.

Pumps With Dynamic Seals:

(3196, CV 3196, LF 3196 only)

1.

Place backplate (444) flat side down on the bench

(Fig. 171).

2.

Place repeller (262) in backplate (444), sleeve side

up.

3.

Place Teflon gasket (264) on backplate (444),

lining up holes.

4.

Place stuffing box cover (184) on backplate (444),

lining up holes.

5.

Install four (4) socket head cap screws (265),

tighten securely.

6.

Install new sealing element into gland.

7.

Install gasket (360Q) and gland (107) on stuffing

box cover (184). Install nuts (355).

8.

Install dynamic seal assembly. Install nuts (370H)

(Fig. 172).

NOTE: Anti-galling compound can be applied to

the sleeve bore to aid in disassembly.

9.

Check stuffing box cover run-out. Rotate indicator

through all 360 degrees. Total indicator reading

greater than 0.005 in. indicates a problem

(Fig. 173).

92

ANSIFAM IOM - 5/08

Fig. 171

Fig. 170

Fig. 172

370H

Fig. 173