Maintenance of bearings – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 50

ANNUAL INSPECTIONS

•

Check the pump capacity, pressure and power. If

pump performance does not satisfy your process

requirements, and the process requirements have

not changed, the pump should be disassembled,

inspected, and worn parts should be replaced.

Otherwise, a system inspection should be done.

INSPECTION INTERVALS

Inspection intervals should be shortened appropriately

if the pumpage is abrasive and/or corrosive,

!

or if the environment is classified as

potentially explosive.

MAINTENANCE OF BEARINGS

!

Throughout this section on bearing lubricat-

ion, different pumpage temperatures are

listed. If the equipment is ATEX certified and

the listed temperature exceeds the applicable

value shown in Table 1 under SAFETY, then

that temperature is not valid. When this

situation occurs please consult with your ITT

Goulds representative.

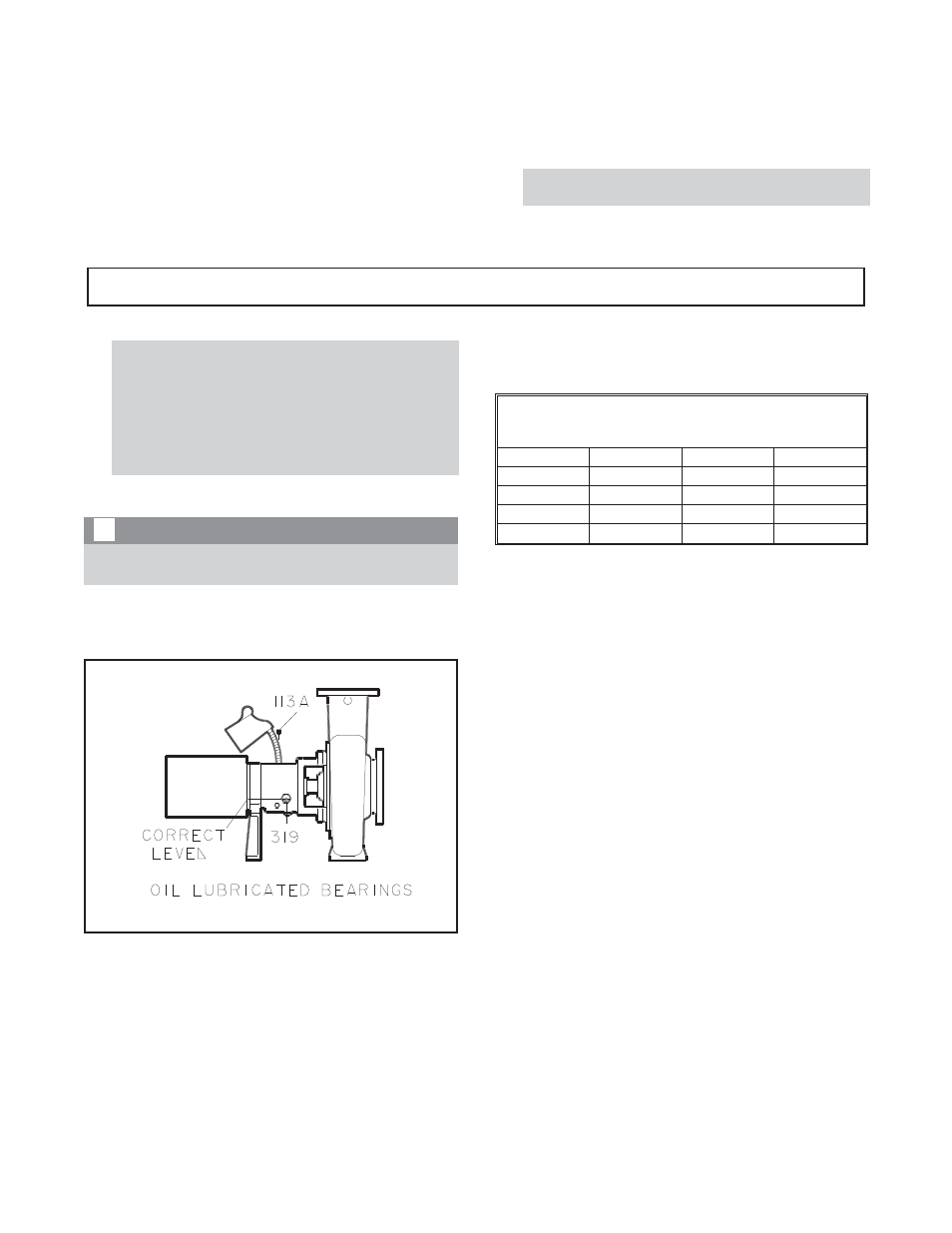

OIL LUBRICATED BEARINGS

s

!

WARNING

Pumps are shipped without oil. Oil lubricated

bearings must be lubricated at the job site.

Remove fill plug (113A) and add oil until level is at the

center of the sight glass (319). Replace fill plug

(Fig. 34) (See Table 4).

Change the oil after 200 hours for new bearings,

thereafter every 2000 operating hours or 3 months

(whichever comes first).

Table 4

Oil Volumes

Frame

Qts.

Oz.

ml

STX

0.5

16

400

MTX

1.3

42

1250

LTX

1.5

48

1400

XLT-X and X17

3

96

3000

A high quality turbine oil with rust and oxidation

inhibitors should be used. For the majority of

operational conditions, bearing temperatures will run

between 120°F (50°C) and 180°F (82°C). In this

range, an oil of ISO viscosity grade 68 at 100°F

(40°C) is recommended. If bearing temperatures

exceed 180°F (82°C), use ISO viscosity grade 100

with Bearing Frame cooling or Finned Tube oil cooler.

The Finned Tube oil cooler is standard with the model

HT 3196 and optional for all other models (See

Table 5). For higher operating temperatures,

pumpage above 350°F (177°C), synthetic lubrication

is recommended.

48

ANSIFAM IOM - 5/08

Fig. 34

!