Appendix vii-1, Warning – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 139

APPENDIX VII-1

Double Row Angular Contact Bearing Installation Instructions

1.

Inspect the shaft (122) to ensure that it is clean,

dimensionally correct, and is free of nicks, burrs,

etc.

2.

Lightly coat the bearing seating with a thin film of

oil.

3.

Remove the bearing (112) from its packaging.

4.

Wipe the preservative from the bearing (112) bore

and outer diameter.

5.

Use an induction heater with a demagnetizing

cycle to heat bearing (112) to an inner ring

temperature of 230 °F (110 °C).

s

!

WARNING

Wear insulated gloves when using a bearing

heater. Bearings will get hot and can cause

physical injury.

6.

Position the bearing (112) on the shaft (122)

against the shoulder and snug the locknut (136)

against the bearing until it is cool. The locknut

prevents the bearing from moving away from the

shaft shoulder as it cools.

NOTE: Regreasable bearing has a single shield.

The outboard bearing is installed with shield

toward impeller.

7.

Remove bearing locknut (136) after bearing (112)

has cooled.

8.

Place lockwasher (382) on shaft (122). Place

tang of lockwasher in keyway of shaft.

9.

Thread locknut (136) onto shaft (122). Tighten

locknut one-eighth (1/8) to one-quarter (1/4) turn

beyond snug. Bend any tang of lockwasher (382)

into a slot of locknut.

NOTE: Tighten locknut if necessary to align the

closest tab of lockwasher with slot on locknut,

but do not overtighten. See Table VII-1 for

maximum locknut torque.

ANSIFAM IOM - 5/08

137

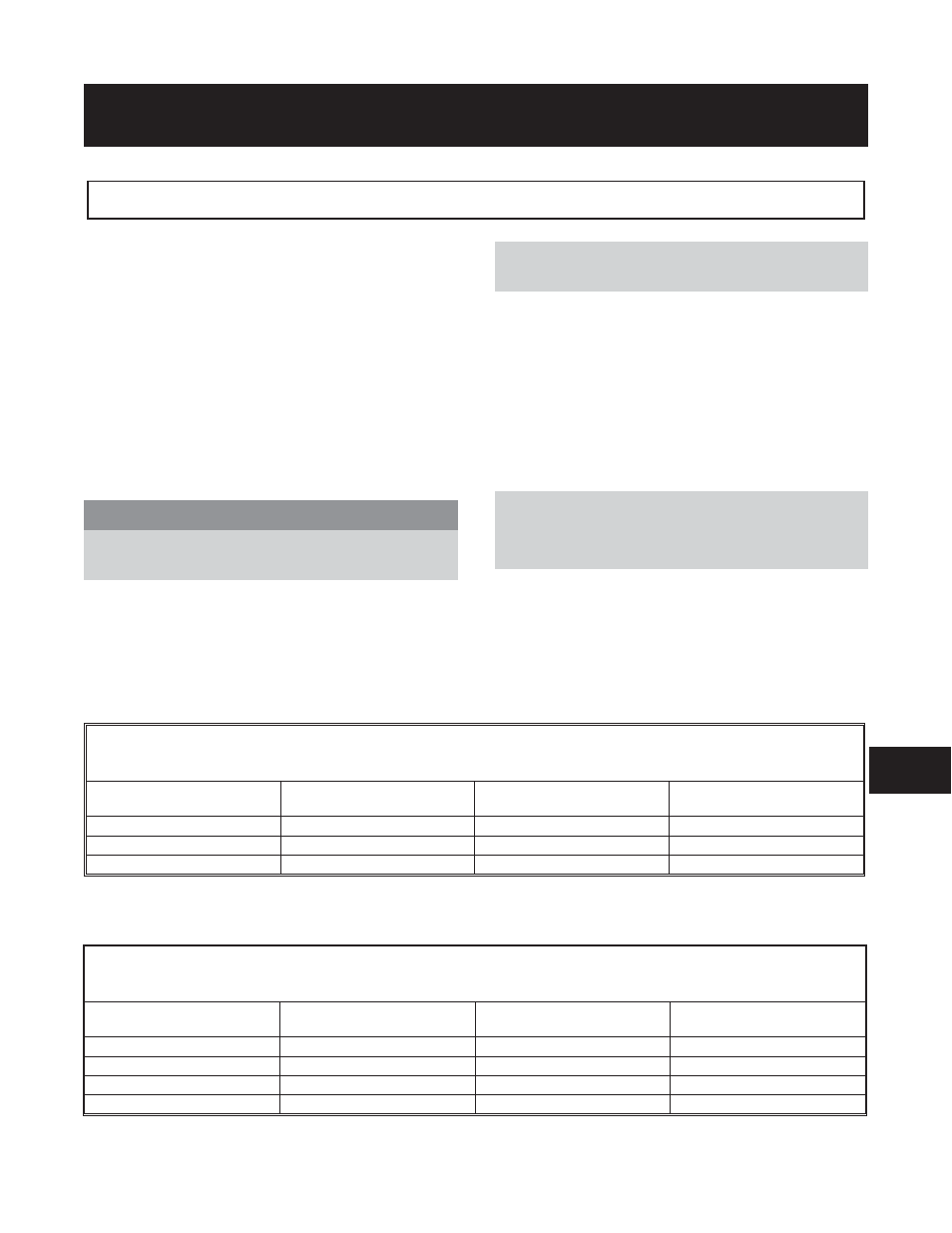

Table VII-2

Maximum Bearing Locknut Torque

Group

Bearing Size

Locknut Size

Maximum Torque

Ft-Lb (N

!m)

STX

7306

N-06

20 (27)

MTX

7309

N-09

50 (68)

LTX

7310

N-10

70 (95)

XLT-X, X17

7313

N-13

140 (190)

Table VII-1

Maximum Bearing Locknut Torque

Group

Bearing Size

Locknut Size

Torque

Ft-Lb (Nm)

STX

5306

N-06

20 (27)

MTX

5309

N-09

50 (68)

XLT-X, X17

5313

N-13

140 (190)

8