Bearing frame, C-face adapter, Dynamic seal repeller – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 72

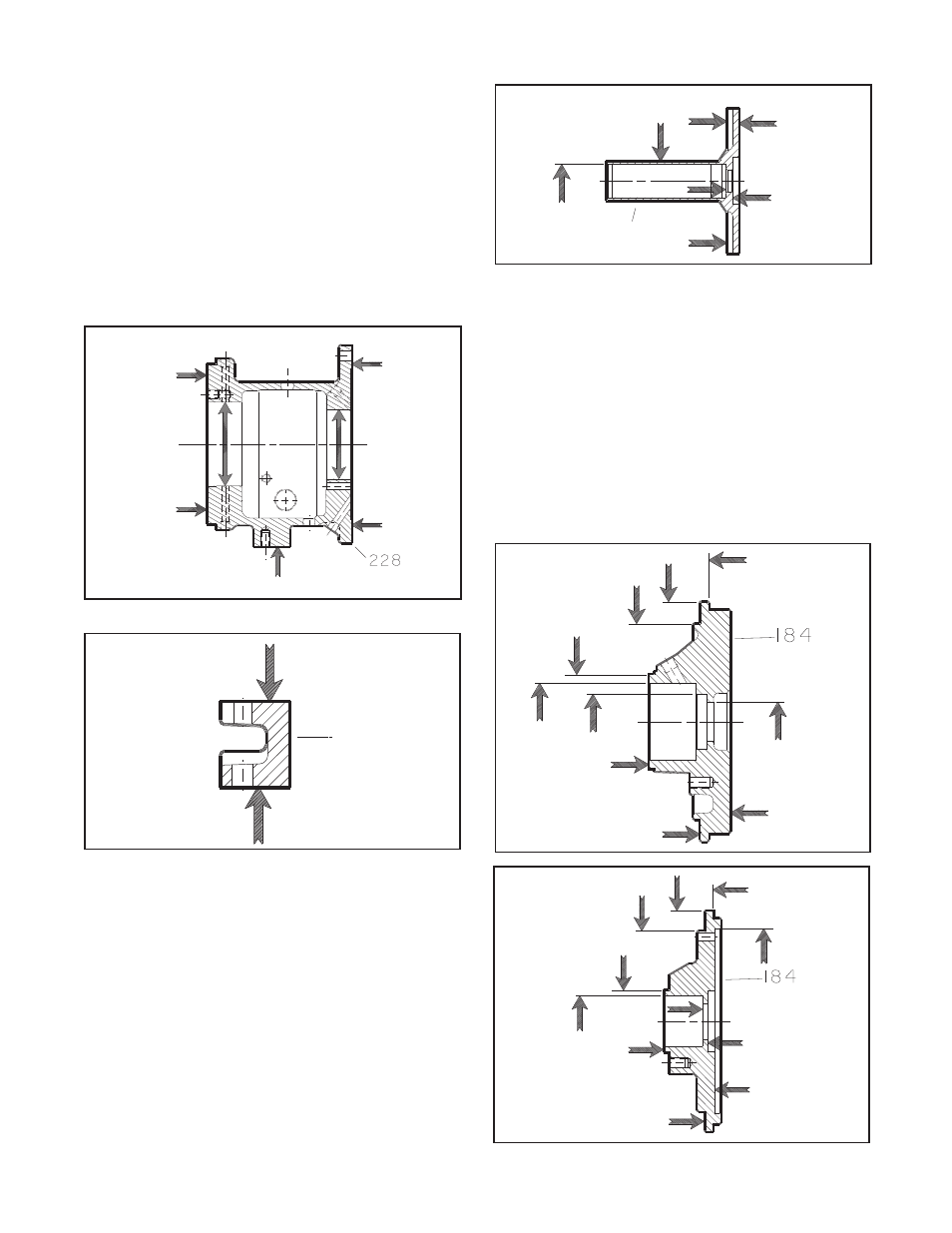

Bearing Frame

1.

Visually inspect bearing frame (228) and frame

foot (241) for cracks. Check frame inside surfaces

for rust, scale or debris. Remove all loose and

foreign material (Figs. 96, 97).

2.

Make sure all lubrication passages are clear.

3.

If frame has been exposed to pumpage, inspect

for corrosion or pitting.

4.

Inspect inboard bearing bore according to

Table 8.

C-Face Adapter

For C-Face adapter inspections, See Appendix V.

Dynamic Seal Repeller

(3196, CV 3196, LF 3196 only)

1.

Inspect dynamic seal repeller (262) vanes for

damage. Replace if grooved deeper than 1/16 in.

(1.6 mm) or if worn evenly more than 1/32 in.

(0.8 mm) (Fig. 98).

2.

Inspect sleeve surface for grooves, pitting or other

damage. Replace if damaged.

Seal Chamber/Stuffing Box Cover and

Dynamic Seal Backplate

1.

Make sure seal chamber/stuffing box cover (184)

and dynamic seal backplate (444) gasket

surfaces, and mounting surfaces, are clean

(Figs. 99 - 107).

2.

Replace if there is any pitting or wear greater than

1/8 in. (3.2 mm) deep.

3.

Inspect machined surfaces and mating faces

noted on Figures 99-107, and clean as

necessary.

70

ANSIFAM IOM - 5/08

Fig. 97

Fig. 98

Fig. 99

BigBore™ Chamber

Fig. 96

Fig. 100

Stuffing Box Cover

241

262