Table 5 lubricating oil requirements, Grease lubricated bearings, Table 6 lubricating grease requirements – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 51: Caution

Table 5

Lubricating Oil Requirements

Pumpage

temperature

below 350°F (177°C)

Pumpage

temperature

above 350°F (177°C)

ISO Grade

VG 68

VG 100

Approx. SSU at

100°F (38°C)

300

470

DIN 51517

C68

C100

Kinem. viscosity at

100°F (40°C)

mm

2

/sec

68

100

Some acceptable lubricants are:

Chevron

GTS Oil 68

Exxon

Teresstic 68 or NUTO H68

Mobil

Mobil DTE 26 300 SSU

@ 100°F (38°C)

Philips

Mangus Oil 315

Shell

Tellus Oil 68

Sunoco

Sunvis 968

Royal Purple

SYNFILM ISO VG 68

Synthetic Lube

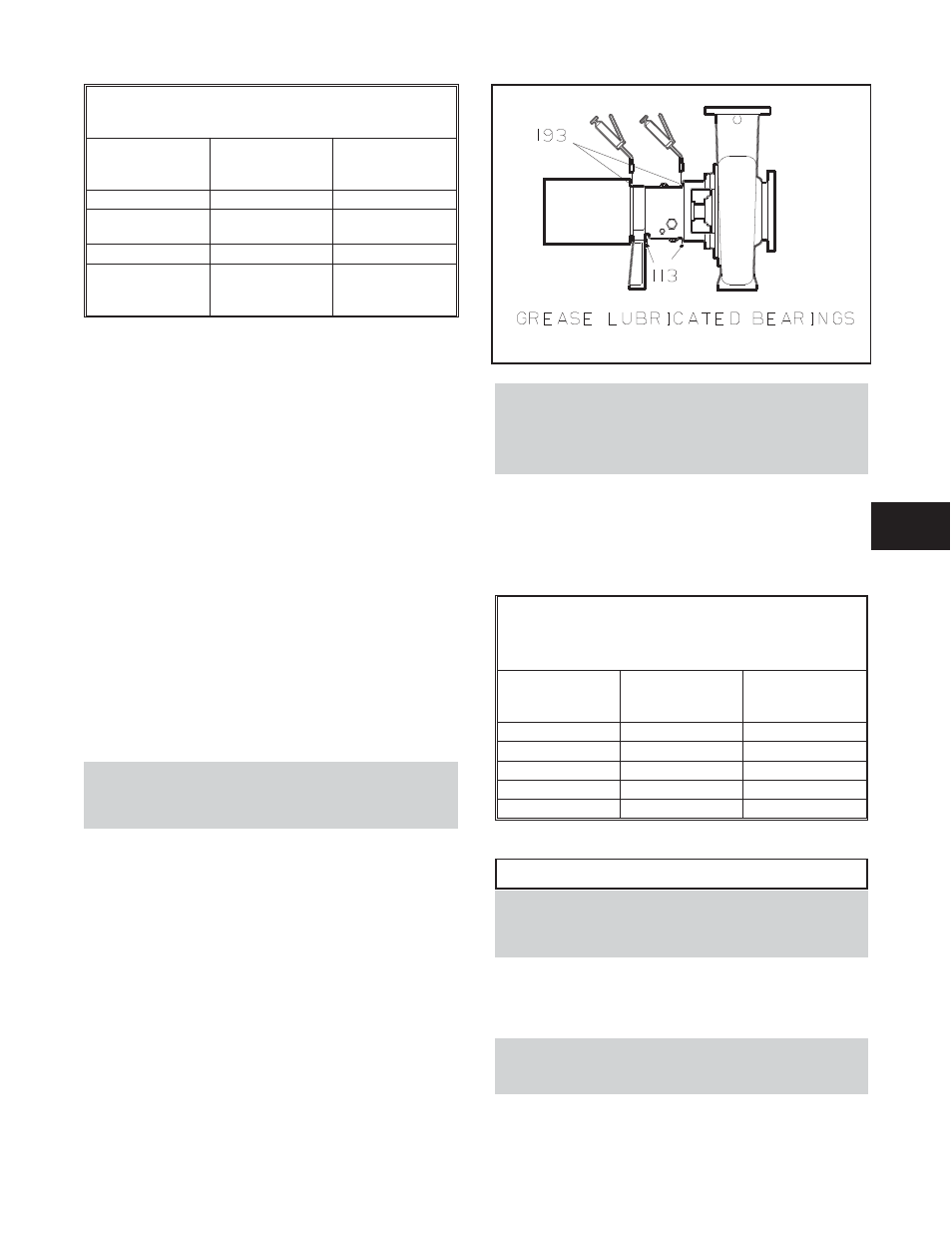

GREASE LUBRICATED BEARINGS

Grease lubricated bearings are pre-lubricated at

the factory. Most pumps have Sunoco 2EP grease.

High temperature units (pumpage temperature greater

than 350° F) use Mobil SCH32. Regrease bearings

every 2000 operating hours or 3 months.

Regrease Procedure:

NOTE: When regreasing, there is danger of

impurities entering the bearing housing. The

grease container, the greasing device, and

fittings must be clean.

1.

Wipe dirt from grease fittings.

2.

Remove 2 grease relief plugs (113) from bottom

of frame.

3.

Fill both grease cavities through fittings with

recommended grease until fresh grease comes

out of the relief holes. Reinstall grease relief

plugs (113).

4.

Ensure frame seals are seated in bearing housing

and, if not, press in place with drains located at

the bottom.

NOTE: The bearing temperature usually rises

after regreasing due to an excess supply of

grease. Temperatures will return to normal

after pump has run and purged the excess

from the bearings, usually two to four hours.

For most operating conditions a lithium based mineral oil

grease of NLGI consistency No. 2 is recommended.

This grease is acceptable for bearing temperatures of

5°F to 230°F (-15°C to 110°C). Bearing temperatures

are generally about 20°F (18°C) higher than bearing

housing outer surface temperature.

Table 6

Lubricating Grease

Requirements

Pumpage

temperature

below 350°F (177°C)

Pumpage

temperature

above 350°F (177°C)

NGLI consistency

2

3

Mobil

Mobilux EP2

SCH32

Exxon

Unirex N2

Unirex N3

Sunoco

Mutipurpose 2EP

SKF

LGMT 2

LGMT 3

$

!

CAUTION

Never mix greases of different consistency

(NGLI 1 or 3 with NGLI 2) or different thickener.

For example never mix a lithium base grease

with a polyurea base grease.

Pumpage temperatures above 350°F (177°C) should

be lubricated by a high temperature grease. Mineral

oil greases should have oxidation stabilizers and a

consistency of NGLI 3.

NOTE: If it is necessary to change grease type

or consistency, the bearings must be removed

and the old grease removed.

ANSIFAM IOM - 5/08

49

5

Fig. 35