Caution start-up precautions – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 45

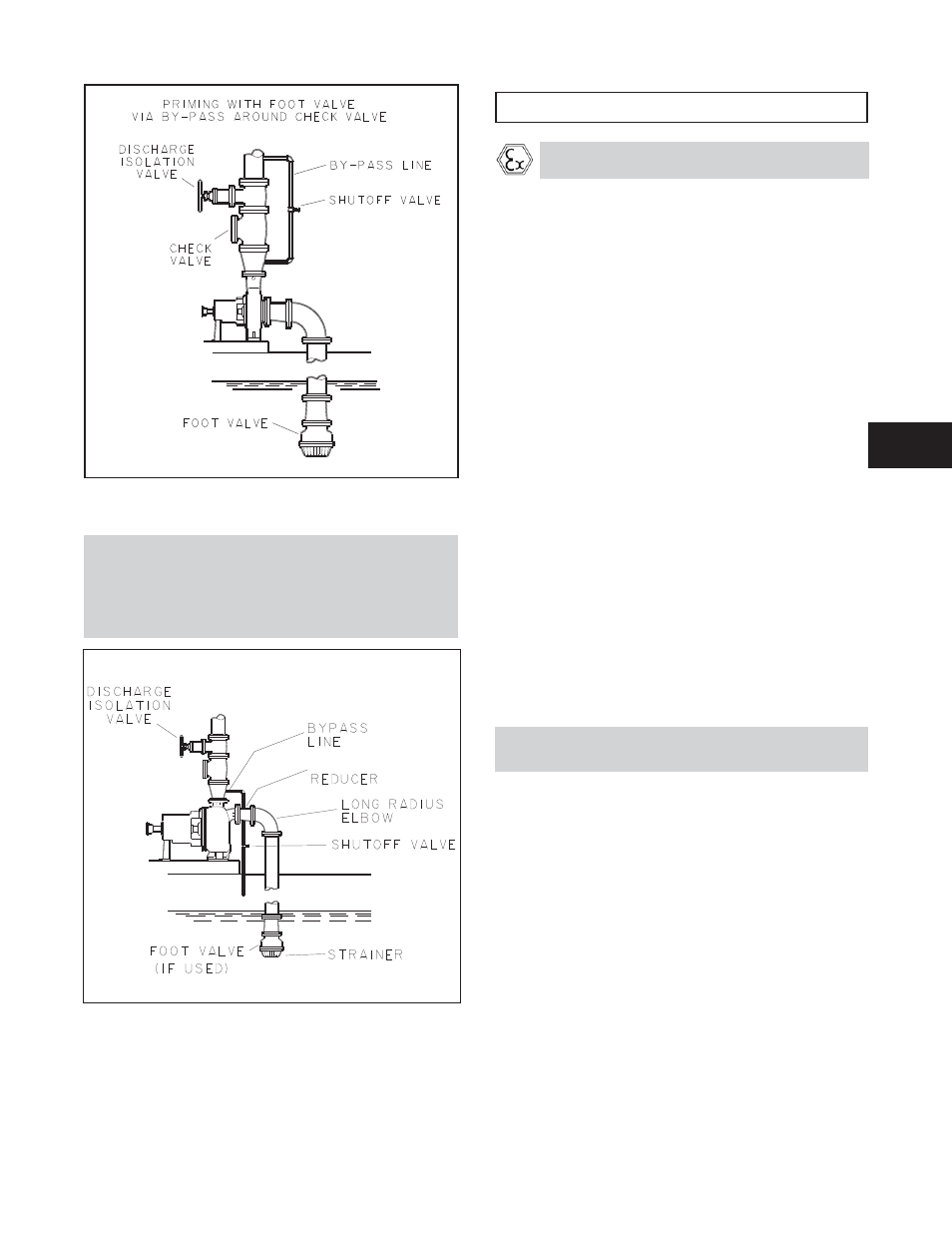

Suction Supply Below Pump - 3796

NOTE: The 3796 is a self-priming pump and

does not require manual priming prior to start-

up (except for the initial charge). However, in a

pressurized system, the pump requires an air

vent or a permanent bypass line in the dis-

charge piping to vent the evacuated air.

Other Methods of Priming:

1.

Priming by Ejector.

2.

Priming by Automatic Priming Pump.

l

!

CAUTION

START-UP PRECAUTIONS

1.

All equipment and personal safety related devices

and controls must be installed and operating

properly.

2.

To prevent premature pump failure at initial

start-up due to dirt or debris in the pipe system,

ensure the system has been adequately cleaned

and flushed.

3.

Variable speed drivers should be brought to rated

speed as quickly as possible.

4.

Variable speed drivers should not be adjusted or

checked for speed governor or overspeed trip

settings while coupled to the pump at initial

start-up. If settings have not been verified,

uncouple the unit and refer to driver

manufacturer’s instructions for assistance.

5.

Running a new or rebuilt pump at slow speeds

may not provide enough flow to adequately flush

and cool the stuffing box bushing’s close running

surfaces.

6.

Pumpage temperatures in excess of 200° F

(93° C) will require warm-up of pump prior to

operation. Circulate a small amount of pumpage

through the pump until the casing temperature is

within 100° F (38° C) of the pumpage temperature

and evenly heated.

NOTE: Warm-up rate should not exceed 1.4° C

(2.5° F) per minute.

ANSIFAM IOM - 5/08

43

Fig. 32

4

CONCENTRIC

Fig. 33

3796 PRIMING IN A PRESSURIZED SYSTEM