Caution – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 80

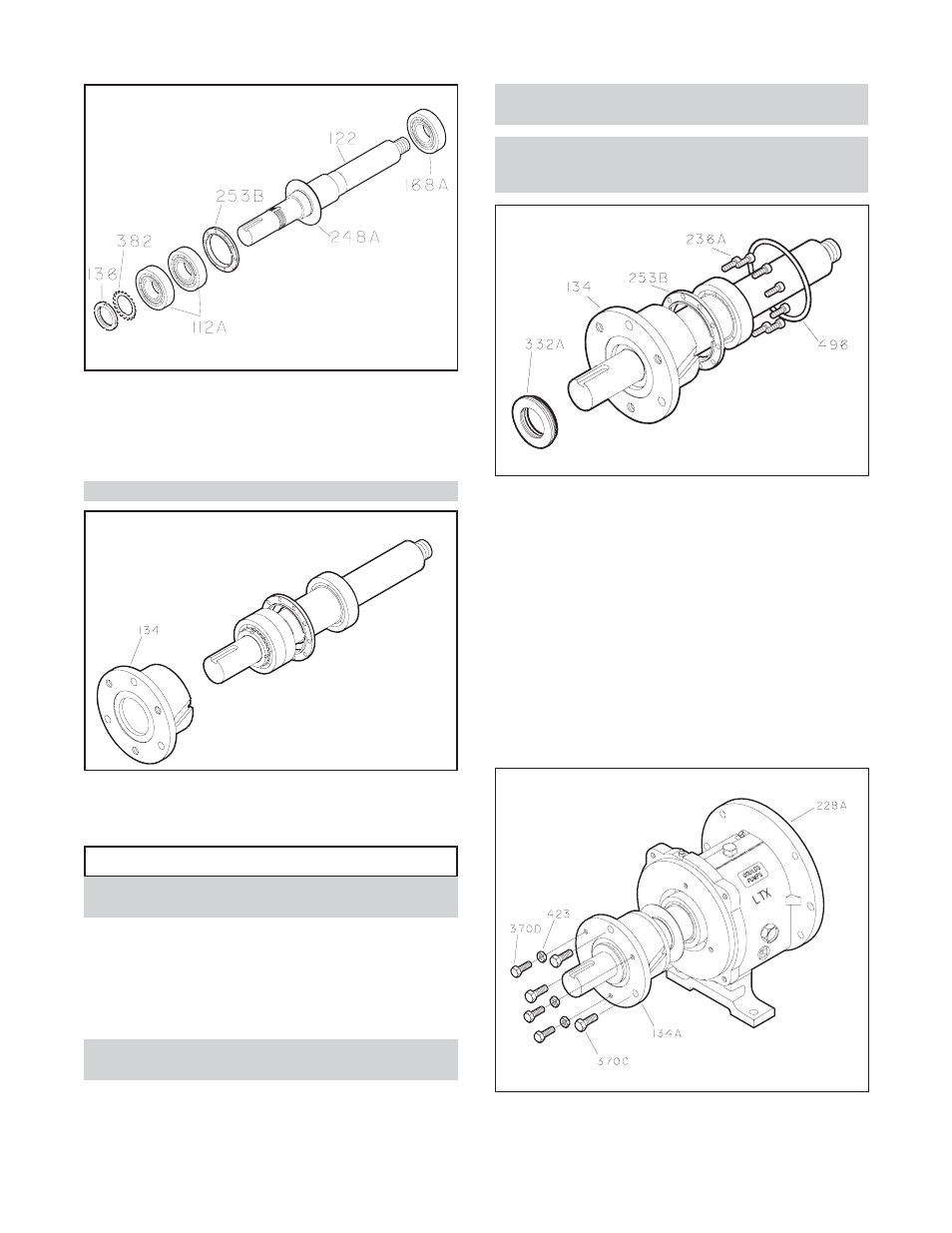

9.

Coat outside of outboard bearing (112A) and

bearing housing (134A) bore with oil.

10. Install bearing housing (134) onto shaft/bearing

assembly (Fig. 117).

NOTE: Do not force assembly together.

11. Install clamp ring bolts (236A). Check shaft for

free turning. Refer to Table 9 for bolt torque

values (Fig. 118).

l

!

CAUTION

Tighten clamp ring bolts (236A) in a criss cross

pattern.

12. Install new O-ring (496).

13. Install outboard labyrinth oil seal (332A) into

bearing housing (134). It is an O-ring fit. Position

the labyrinth seal drain slots at the bottom

(6 o’clock) position.

NOTE: See Appendix IV or VIII for further

instructions on Labyrinth Seal installation.

NOTE: Make sure the keyway edges are free of

burrs.

NOTE: Cover the keyway lengthwise with a

piece of electrical tape prior to installing the

labyrinth seal. This will protect the O-rings.

14. Coat outside of bearing housing (134A) with oil.

15. Coat all internal surfaces of bearing frame (228)

with oil.

16. Install shaft assembly into frame (228A), making

sure to leave approximately 0.125 in. (3.175 mm)

clearance between the face of the bearing

housing and bearing frame. Check shaft for free

turning (Fig. 119).

17. Install clamping bolts (370C) into bearing housing

(134A). Hand tighten.

18. Install jacking bolts (370D) with locking nuts (423)

into housing (134A). Hand tighten.

78

ANSIFAM IOM - 5/08

Fig. 116

Fig.117

Fig. 118

Fig. 119