Appendix iii, Alignment, Set up – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 129: Measurement, Angular alignment

APPENDIX III

Alignment

Alignment procedures must be followed to

prevent unintended contact of rotating

parts. Follow coupling manufacturer’s

coupling installation and operation

procedures.

SET UP

1.

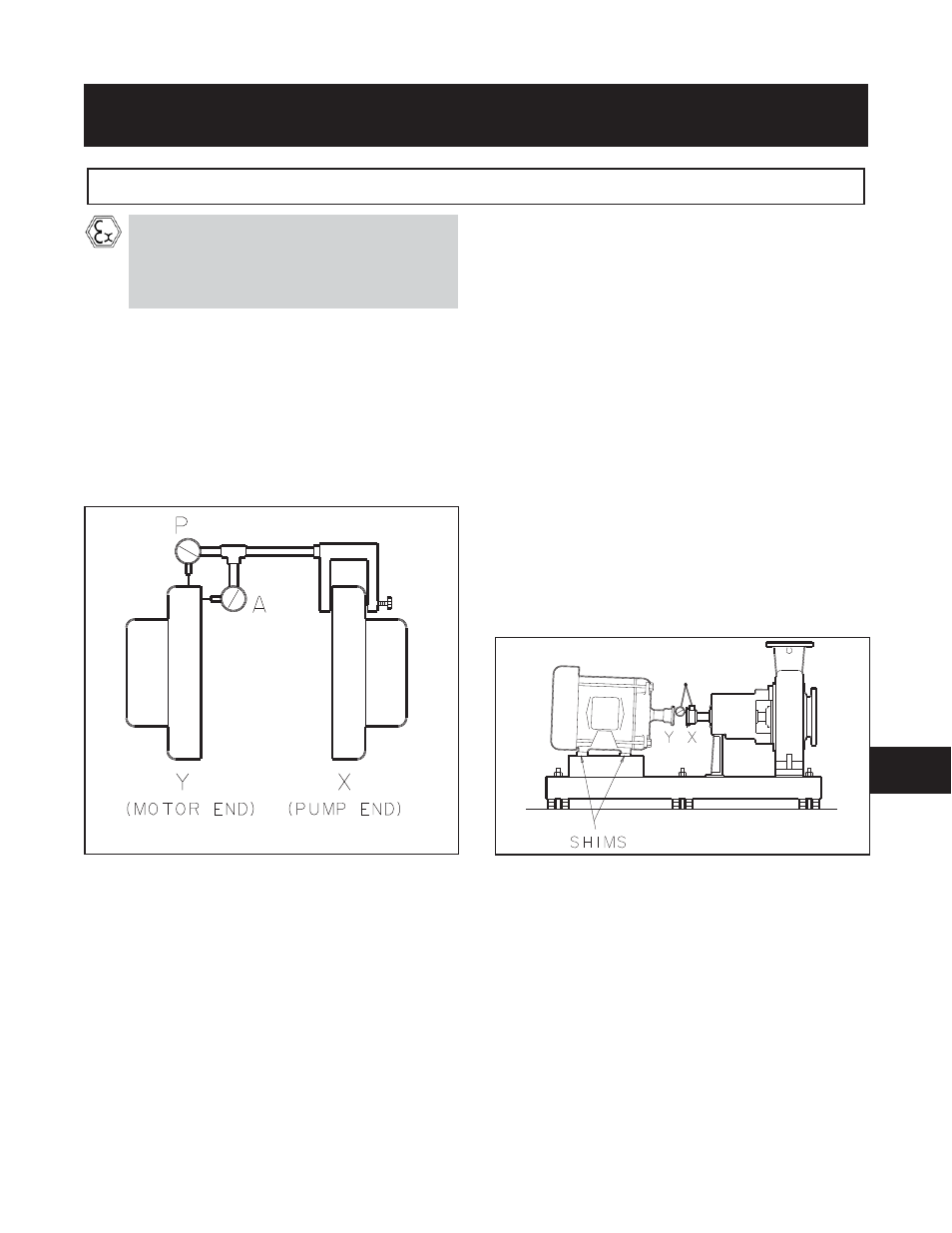

Mount two dial indicators on one of the coupling

halves (X) so they contact the other coupling half

(Y) (Fig. III-1).

2.

Check setting of indicators by rotating coupling

half X to ensure indicators stay in contact with

coupling half Y but do not bottom out. Adjust

indicators accordingly.

MEASUREMENT

1.

To ensure accuracy of indicator readings, always

rotate both coupling halves together so indicators

contact the same point on coupling half Y. This

will eliminate any measurement problems due to

runout on coupling half Y.

2.

Take indicator measurements with driver feet

hold-down bolts tightened. Loosen hold down

bolts prior to making alignment corrections.

3.

Take care not to damage indicators when moving

driver during alignment corrections.

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A

(Angular indicator) does not vary by more that .002 in.

(.05 mm) as measured at four points 90° apart.

Vertical Correction (Top-to-Bottom)

1.

Zero indicator A at top dead center (12 o’clock) of

coupling half Y.

2.

Rotate indicators to bottom dead center

(6 o’clock). Observe needle and record reading.

3.

Negative Reading - The coupling halves are

further apart at the bottom than at the top. Correct

by either raising the driver feet at the shaft end

(add shims) or lowering the driver feet at the other

end (remove shims), (Fig. III-2).

Positive Reading - The coupling halves are

closer at the bottom than at the top. Correct by

either lowering the driver feet at the shaft end

(remove shims) or raising the driver feet at the

other end (add shims).

4.

Repeat steps 1-3 until indicator A reads .002 in

(.05 mm) or less.

Horizontal Correction (Side-to-Side)

1.

Zero indicator A on left side of coupling half Y, 90°

from top dead center (9 o’clock).

2.

Rotate indicators through top dead center to the

right side, 180° from the start (3 o’clock). Observe

needle and record reading.

3.

Negative Reading - The coupling halves are

further apart on the right side than the left. Correct

by either sliding the shaft end of the driver to the

left or the other end to the right.

ANSIFAM IOM - 5/08

127

8

Fig. III-1

Fig. III-2