Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 87

4.

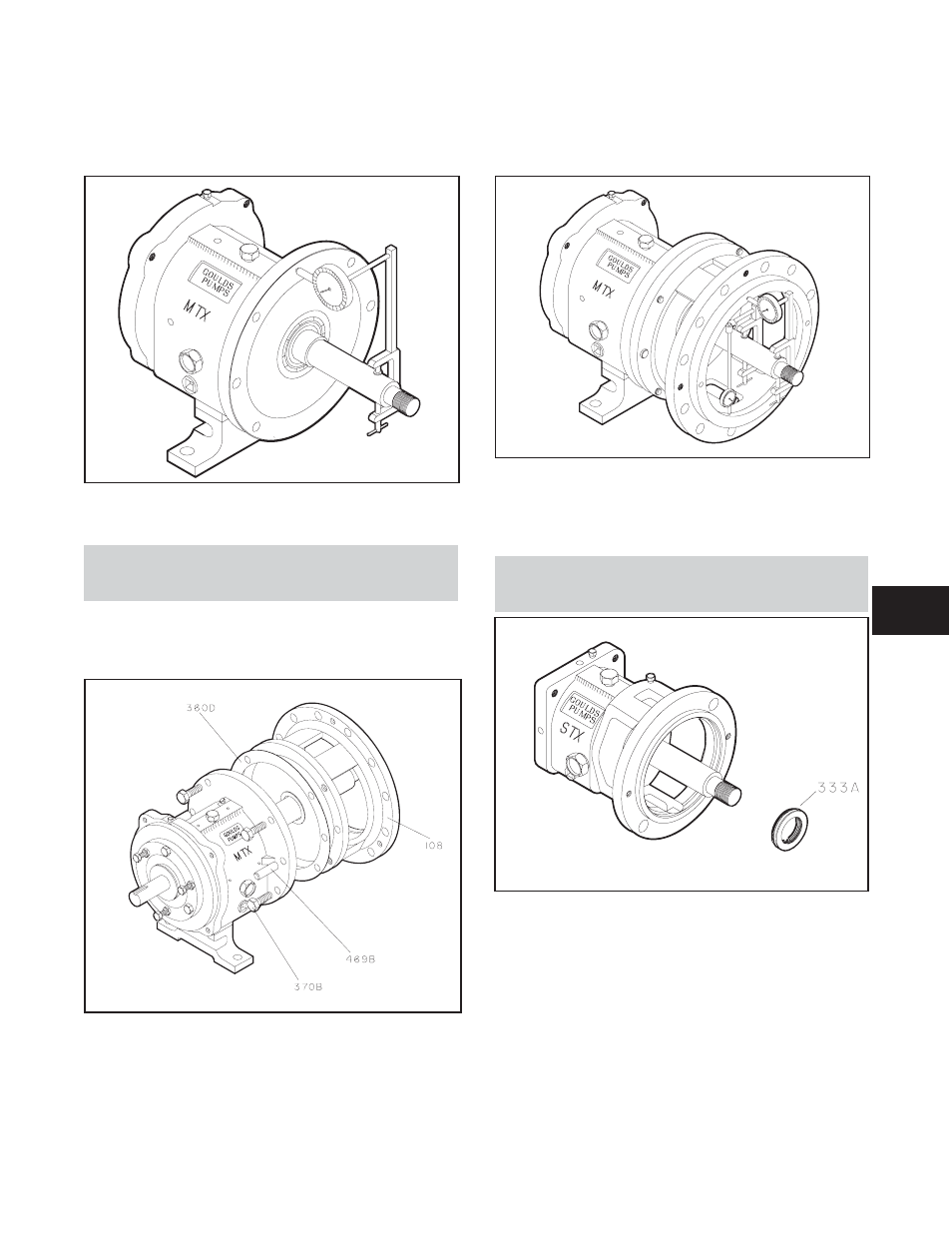

Check frame face run out. Rotate shaft so

indicator rides along the fit for 360 degrees. If total

indicator reading is greater than 0.001 in. (.025 mm)

disassemble and determine cause (Fig. 141).

5.

Place manila gasket (360D) on frame (228)

(Fig. 142).

NOTE: The gasket is designed to fit one way

only. The dowel pins (469B) may be started in

their holes to hold the gasket in place.

6.

Install frame adapter (108), onto frame assembly.

Align bolt holes and dowel locations with those on

frame (Fig. 142).

7.

Install dowel pins (469B) and bolts (370B).

Tighten bolts to Table 9 torque specifications in a

crisscross pattern.

8.

Check adapter fits. Rotate shaft through 360

degrees. If total indicator reading is greater than

.005 in. (.13 mm), determine the cause and

correct before proceeding (Fig. 143).

9.

Install inboard labyrinth oil seal (333A) into

adapter (108) / bearing frame (228). It is an

O-ring fit. Position the labyrinth seal drain slots at

the bottom (6 o’clock) position. (Fig. 144).

NOTE: For detailed labyrinth seal installation

instructions, see Appendix IV or VIII, Labyrinth

Seal Installation Instructions.

ANSIFAM IOM - 5/08

85

6

Fig. 141

Fig. 142

Fig. 143

Fig. 144

STX