Appendix i, Frame lubrication conversion, Lubrication conversion – Goulds Pumps ANSI FAMILY IOM (ATEX Compliant) - IOM User Manual

Page 121: Caution, Conversion from flood oil to pure oil mist, A. non-vented oil mist system, B. vented oil mist system

APPENDIX I

Frame Lubrication Conversion

Lubrication Conversion

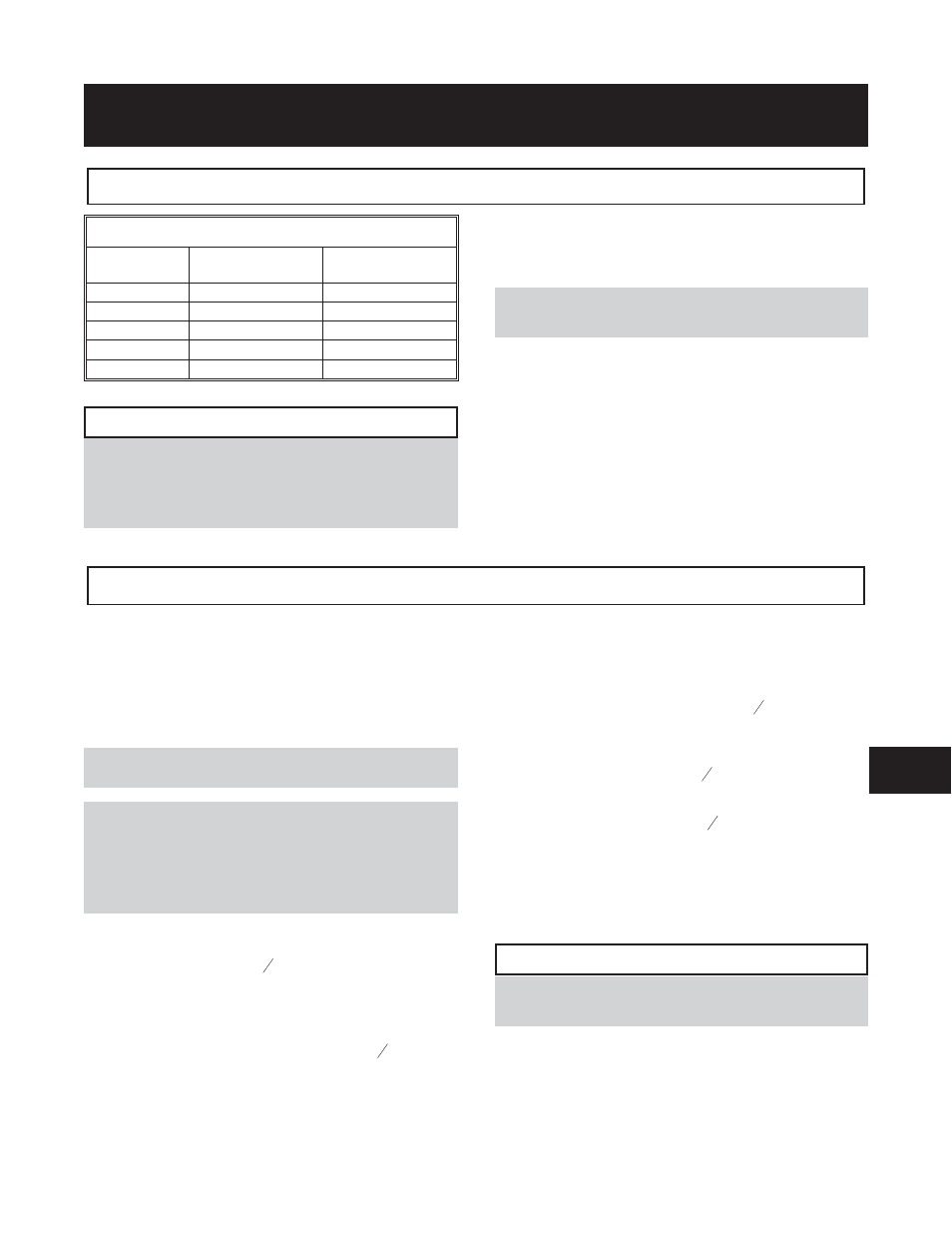

Pumpage Temperature

below 350°F (177°C)

Pumpage Temperature

above 350°F (177°C)

NLGI Consistency

2

3

Mobil

Mobilux EP2

SCH32

Exxon

Unirex N2

Unirex N3

Sunoco

Multipurpose 2EP

SKF

LGMT 2

LGMT 3

l

!

CAUTION

Never mix greases of different consistency (NLGI

1 or 3 with NLGI 2) or different thickener soaps

(sodium or calcium with lithium). The consistency

usually becomes softer and will not provide

adequate lubrication to the bearings.

Pumpage temperatures above 350°F (177°C) should

be lubricated by a high temperature grease. Mineral

oil greases should have oxidation stabilizers and a

consistency of NLGI 3.

NOTE: If it is necessary to change grease type

or consistency, the bearings must be removed

and the old grease removed.

FRAME LUBRICATION CONVERSION

Conversion from Flood Oil to Pure Oil Mist

There are several ways to apply oil mist. ITT Goulds

has designed X-Series Power Ends to accept a

variety of oil mist configurations. The following

instructions are written for two popular systems in

use.

NOTE: Make sure that pipe threads are clean

and apply thread sealant to plugs & fittings.

NOTE: The LTX requires that the bearing

housing be changed when making the

conversion from flood oil to oil mist lubrication.

After the proper bearing housing has been

installed follow the instructions as they apply

to STX, MTX, XLT-X, X17.

A. Non-Vented Oil Mist System

1.

Attach oil mist inlet to

1

4

" NPT connection at top,

outboard end of frame (plugged with 408H allen

head plug), and top, center of frame (plugged with

113A hex head plug).

2.

Attach drain at bottom center of frame

3

8

" NPT

hole (plugged with 408A magnetic drain plug).

3.

Follow oil mist generator manufacturer’s

instructions for oil mist volume adjustment, and

operation.

B. Vented Oil Mist System

1.

Attach oil mist inlet connection to

1

4

" NPT

connections at outboard and inboard ends of

frame.

2.

Attach vent connection at

1

2

" NPT hole located in

top center of frame.

3.

Attach drain connection at

3

8

" NPT hole located at

bottom center of frame (plugged with 408A

magnetic drain plug).

4.

Follow oil mist generator manufacturer’s

instructions for oil mist volume adjustment and

operation.

l

!

CAUTION

Oil mist falls under Title III of the Clean Air Act

and must be controlled or the user will be

subject to penalty.

ANSIFAM IOM - 5/08

119

8