Warning ! 11, Figure ii.e.1 – Myron L CTCIITD User Manual

Page 15

C.

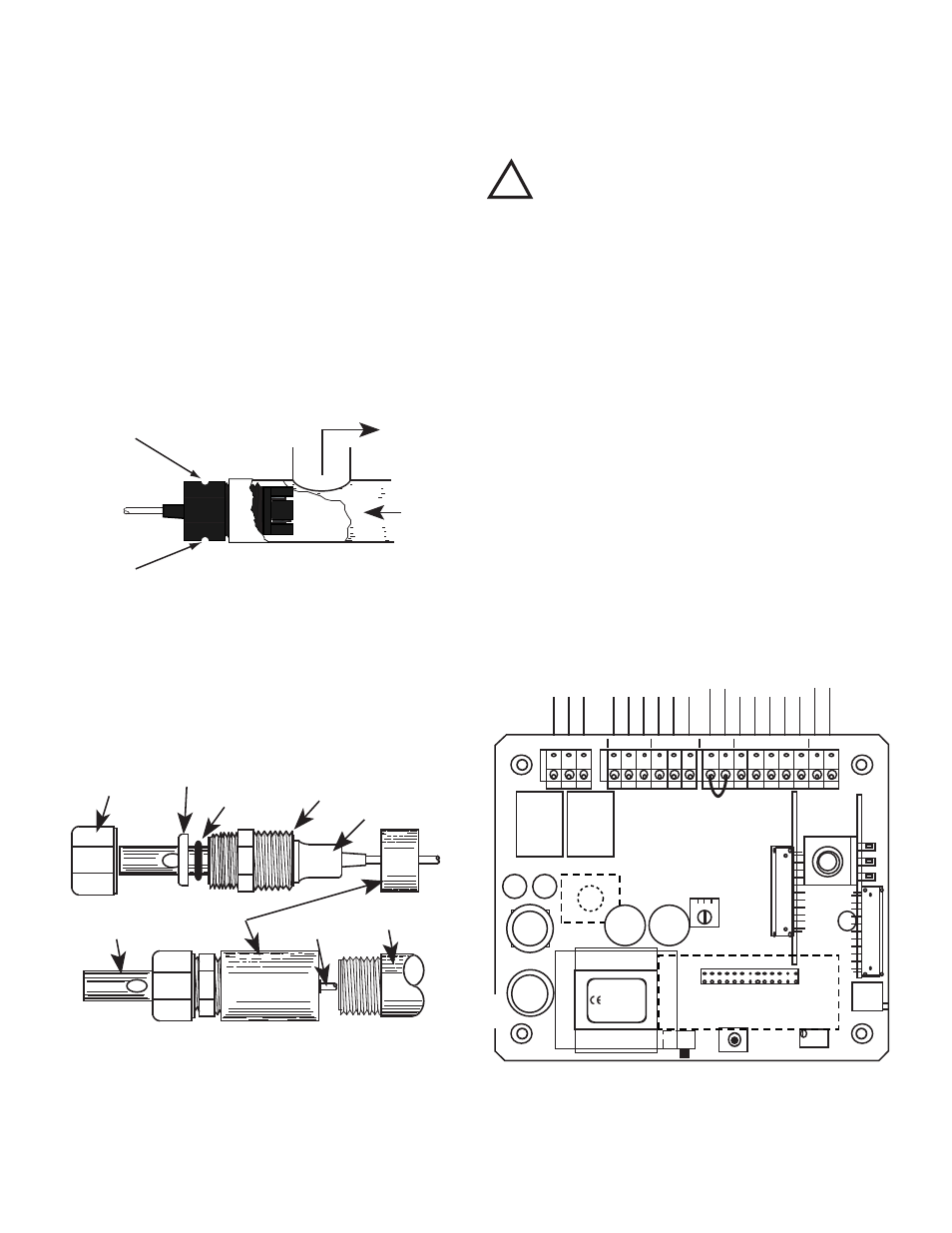

SENSOR INSERTION/IMMERSION MOUNTING

The Sensor’s mounting orientation must provide a continuous and

adequate circulation flow to prevent the trapping of air bubbles

within the Sensor’s electrode area (CSAR shown in figure II.D.1).

Failure to do so will result in conditions that may prevent the

Sensor from functioning properly. The CSAR sensor is designed

for insertion (in-line installation). The optional CS51R sensor may

be ordered and installed as either insertion, or immersion (see

figure II.D.2).

1. INSERTION MODE (in-line installation)

Use approved sealant, i.e. Teflon tape as required.

1. Pre-wind CSAR sensor before installation. Rotate sensor

counter clockwise (CCW) (as if removing sensor) 4-5

turns before installing into fitting.

2. Insert the Sensor Fitting assembly into the “T” fitting with

electrode aligned with direction of flow as shown in figure

II.D.1. and tightly secure. Note: The CS51R installs in

the same manner. (but does not require any turns)

2. IMMERSION OR DIP SENSOR ASSEMBLY

Use approved sealant, i.e. Teflon tape as required.

1. Verify that the CS51R Sensor’s Fitting assembly is

properly assembled as shown in figure II.D.2.

2. Insert and pull the Sensor’s cable through the extension

tube and then tightly attach extension tube to Sensor

assembly as shown in figure II.D.2.

D.

ELECTRICAL INSTALLATION

As shipped from the factory, the input power cable, the two

(2) output connectors, and the sensor are pre-wired to the

controller. Electrical connection simply requires plugging in

the appropriate valve and pump, and input power as labeled.

A device to disconnect the Model CTCII from the power

supply is required. It is recommended that this switch or

circuit breaker be labeled as the disconnection device for the

Model CTCII.

WARNING: All CTCII controllers are factory set for 115 VAC.

Before starting, ensure the input power “115/230” selection

is correct for your requirements. Failure to do so is beyond

the responsibility of the Myron L Company. See section II.D.1.

below and figure II.E.1.

NOTE: Some models, if ordered, have either a 24 VAC or a 24

VDC input power requirement - check labels carefully.

The following instructions are if the input power, output power or

sensor cables are removed.

The electrical installation procedures provided in this manual are

common to all CTCII controllers. Unless otherwise instructed,

refer to figure II.E.1. for the CTCII controller’s terminal block

connector wiring designations.

CSAR INSERTION MODE

Figure II.D.1

OUT

IN

DOT

DOT

CABLE

SENSOR TIP

COUPLING

3/4" NPT

EXTENSION TUBE

SECURING NUT

PLASTIC

WASHER

O-RING

THREADED FITTING

3/4" FNPT

FLANGE

IMMERSION OR DIP CS51R SENSOR

ASSEMBLY SHOWN

Figure II.D.2

FUSE

ELECTRICAL CONNECT DIAGRAM

Figure II.E.1

DIS

TRANSFORMER

DISPLAY

Yel

FEED

PUMP

BLEED

VALVE

POWER

FLOW

SWITCH

SENSOR

0-10VDC

C4AM

LTM

HYST

CAL

PWR

C GD

PWR

C GD

PWR

C GD

FS

BK WT RD GN NU R- R+

Flow Switch

Jumper -

Remove if

flow switch

installed.

TDS

COND

MYRON L

COMPANY

CTCII

BL

K

W

H

T

R

ED

G

R

N

N

EU R- R+

PO

W

ER

C

O

M

M

G

R

O

U

N

D

PO

W

ER

C

O

M

M

G

R

O

U

N

D

PO

W

ER

C

O

M

M

G

R

O

U

N

D

INPUT POWER

SENSOR

FEED

PUMP

BLEED

VALVE

FLOW

SWITCH

0-10 VDC

EC

SWITCH

BLEED FEED

CAP

CAP

RELAY

RELAY

115/230 VAC

SELECT SWITCH

!

WARNING !

11