Myron L 760-A Aquaswitch User Manual

Page 6

NOTE:

The 760-A Aquaswitch is not designed to operate with a Cell cable

length that exceeds 100' (30 meters).

3 If at all possible, mount the Controller at eye level for

viewing convenience.

2.2.1 SURFACE MOUNTING

NOTE:

Surface mounting will require two (2) user supplied 1/4” 20

mounting screws See, Fig. 2-1 for hole drilling locations. For ease

of surface mounting, a surface mounting plate is available.

Order Part No.: SMP50 for Aquaswitch

SMP60 for 760-A Aquaswitch

STEP 1 Select your site location. Mark and drill the two (2) required

mounting holes.

STEP 2 lace the mounting threads in alignment with the surface

mounting holes.

STEP 3 Insert and securely fasten the two (2)1/4':20 mounting

screws.

2.2.2 PANEL MOUNTING INSTALLATION

A panel mounting fastening kit is provided with all Aquaswitch/

760-A Aquaswitch enclosures. Panel mounting will require the use

of the fastening kit’s two (2) 4-40 mounting screws/nuts or two

(2) #4 x 1/2 “ sheet metal screws. See Fig. 2-1 for panel cutout

dimensions.

STEP 1 Select your site location, mark the appropriate pane I cut

out and complete the necessary panel cut.

STEP 2 Carefully unfasten and separate the front panel from its

enclosure.

STEP 3 Disconnect all panel cable(s)/wires from the enclosure’s

component board(s).

STEP 4 Slide the enclosure through the panel cutout until its flange

contacts the panel.

STEP 5 Insert mounting screws through the flange mounting holes

and tightly secure.

STEP 6 Reconnect all panel cable(s)/wires. (See Fig. 4-1)

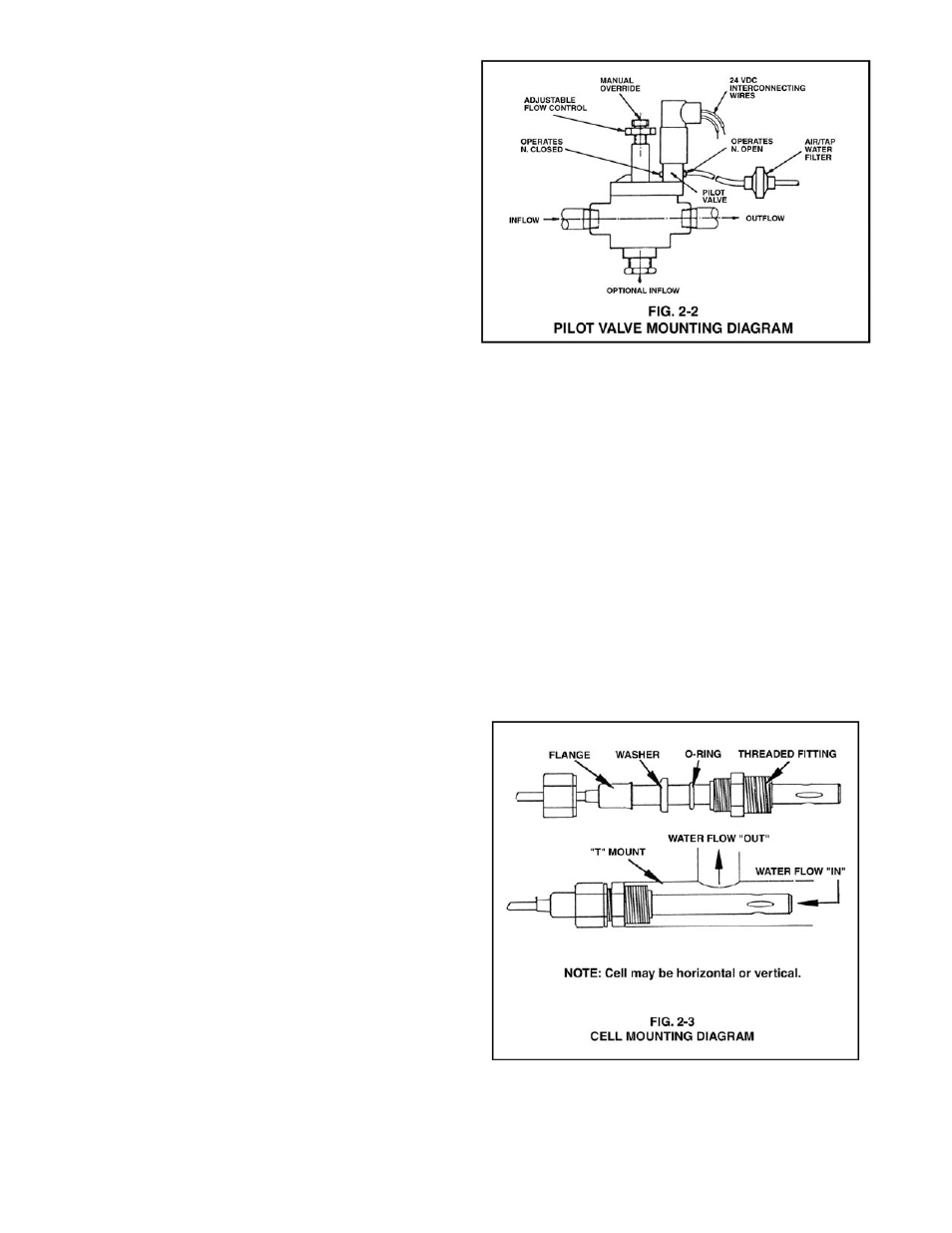

2.2.3 HP SOLENOID PILOT VALVE INSTALLATION

STEP 1 Insert the pilot valve unit so that the systems’ INFLOW

source and OUTFLOW process piping connecting ends

are inserted into the valve as shown in Fig. 2-2.

STEP 2 Repeat STEP 1 until all appropriate pilot valve units have

been installed.

NOTE:

The number of pilot valves used will be based upon the user’s

desired application.

2.2.4 CELL INSTALLATION (MODEL 760-A ONLY)

NOTE:

Fig. 2-3 illustrates how to properly assemble and install the CS10

Cell assembly into a “T” type mounting fixture. Improper assembly

could result in damage to equipment and/or property.

A CS10 Cell’s mounting orientation must provide a continuous

and adequate circulation flow to prevent the trapping of air bubbles

within the Cell’s electrode area. Failure to do so will result in

conditions that will prevent the cell from functioning properly.

STEP 1 Verify that the Cell components are properly

assembled.

STEP 2 Insert the Cell assembly into the “T” mounting fixture as

shown in Fig. 2-3 and tightly secure.

4