Mechanical installation, General, Before installation – Beijer Electronics Industrial Inverter E2 User Manual

Page 9: Ul compliant installation, Guidelines for enclosure mounting – ip20 units

9

3. Mechanical Installation

3.1. General

The drive should be mounted in a vertical position only on a flat, flame resistant vibration free mounting using the integral holes or

DIN Rail clip (Frame Sizes 1 and 2 only). Do not mount flammable material close to the drive

The drive must be installed in a pollution degree 1 or 2 environment only.

Ensure that the minimum cooling air gaps are left clear

Ensure that the ambient temperature range does not exceed the permissible limits for the drive given in section 10.1

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the drive.

3.2. Before Installation

Carefully Unpack the BFI drive and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the drive in its original box until required. Storage should be clean and dry and within the

temperature range –40°C to +60°C

3.3. UL Compliant Installation

Refer to section 9.3 on page 27 for Additional Information for UL Compliance.

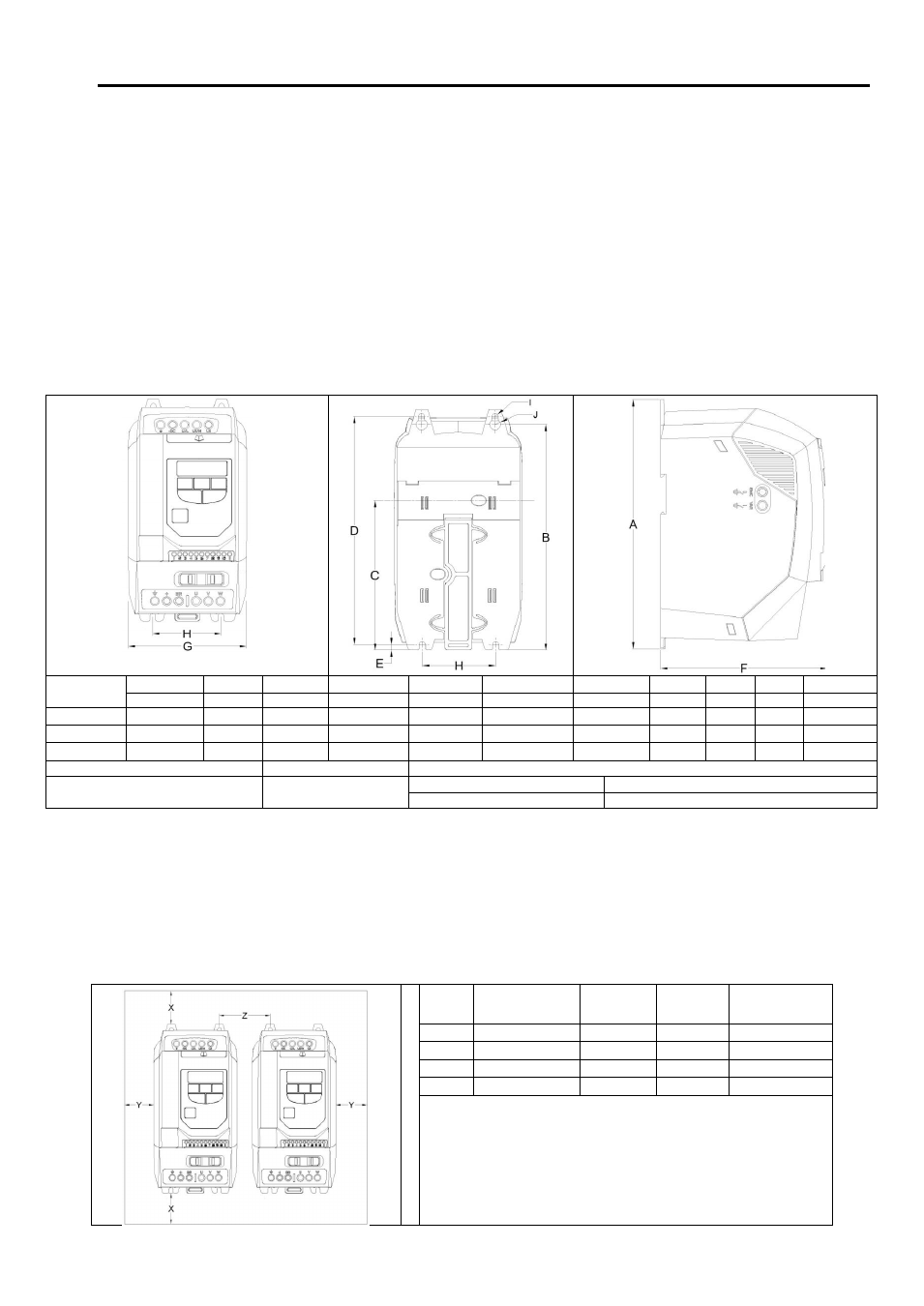

3.4. Mechanical Dimensions and Mounting – IP20 Open Units

Drive Size

A / Height

B

C

D

E

F / Depth

G / Width

H

I

J

Weight

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

kg

1

173

160

109

162

5

123

82

50

5.5

10

1,0

2

221

207

137

209

5.3

150

109

63

5.5

10

1,7

3

261

246

-

247

6

175

131

80

5.5

10

3,2

Mounting Bolts

All Frame Sizes

4 x M4

Tightening Torques

All Frame Sizes

Control Terminals

0.5 Nm

Power Terminals

1 Nm

3.5. Guidelines for Enclosure Mounting – IP20 Units

IP20 drives are suitable for use in pollution degree 1 environments, according to IEC-664-1. For pollution degree 2 or higher

environments, drives should be mounted in a suitable control cabinet with sufficient ingress protection to maintain a pollution

degree 1 environment around the drive.

Enclosures should be made from a thermally conductive material.

Where vented enclosures are used, there should be venting above the drive and below the drive to ensure good air circulation – see

the diagram below. Air should be drawn in below the drive and expelled above the drive.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the

drive heatsink. The drive manufacturer the following minimum sizes for drives mounted in non-ventilated metallic enclosures:-

Drive

Size

X

Above & Below

Y

Either Side

Z

Between

Recommended

airflow

mm

mm

mm

CFM (m

3

/min)

1

50

50

33

0.31

2

75

50

46

0.31

3

100

50

52

0.74

Note:

Dimension Z assumes that the drives are mounted side-by-side with

no clearance.

Typical drive heat losses are 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of

the drive MUST be maintained at all times.