Gland plate and lock off, Removing the terminal cover, Routine maintenance – Beijer Electronics Industrial Inverter E2 User Manual

Page 11: 11 3.8. gland plate and lock off

11

3.8. Gland Plate and Lock Off

The use of a suitable gland system is required to maintain the appropriate IP / Nema rating. Cable entry holes are already moulded into the

drive plastic and are fixed sizes as listed below:

Please take care when drilling to avoid leaving any particles within the product.

Cable Gland recommended Hole Sizes & types:

Power & Motor Cables

Control & Signal Cables

Moulded Hole Size

Imperial Gland

Knockout Size

Imperial Gland

Size 1

22mm

PG13.5

22mm

PG13.5

Size 2 & 3

27mm

PG21

22mm

PG13.5

Flexible Conduit Hole Sizes:

Drill Size

Trade Size

Size 1

28mm

¾ in

Size 2 & 3

35mm

1 in

UL rated ingress protection ("Type " ) is only met when cables are installed using a UL recognized bushing or fitting for a flexible-

conduit system which meets the required level of protection ("Type")

For conduit installations the conduit entry holes require standard opening to the required sizes specified per the NEC

Not intended for rigid conduit system

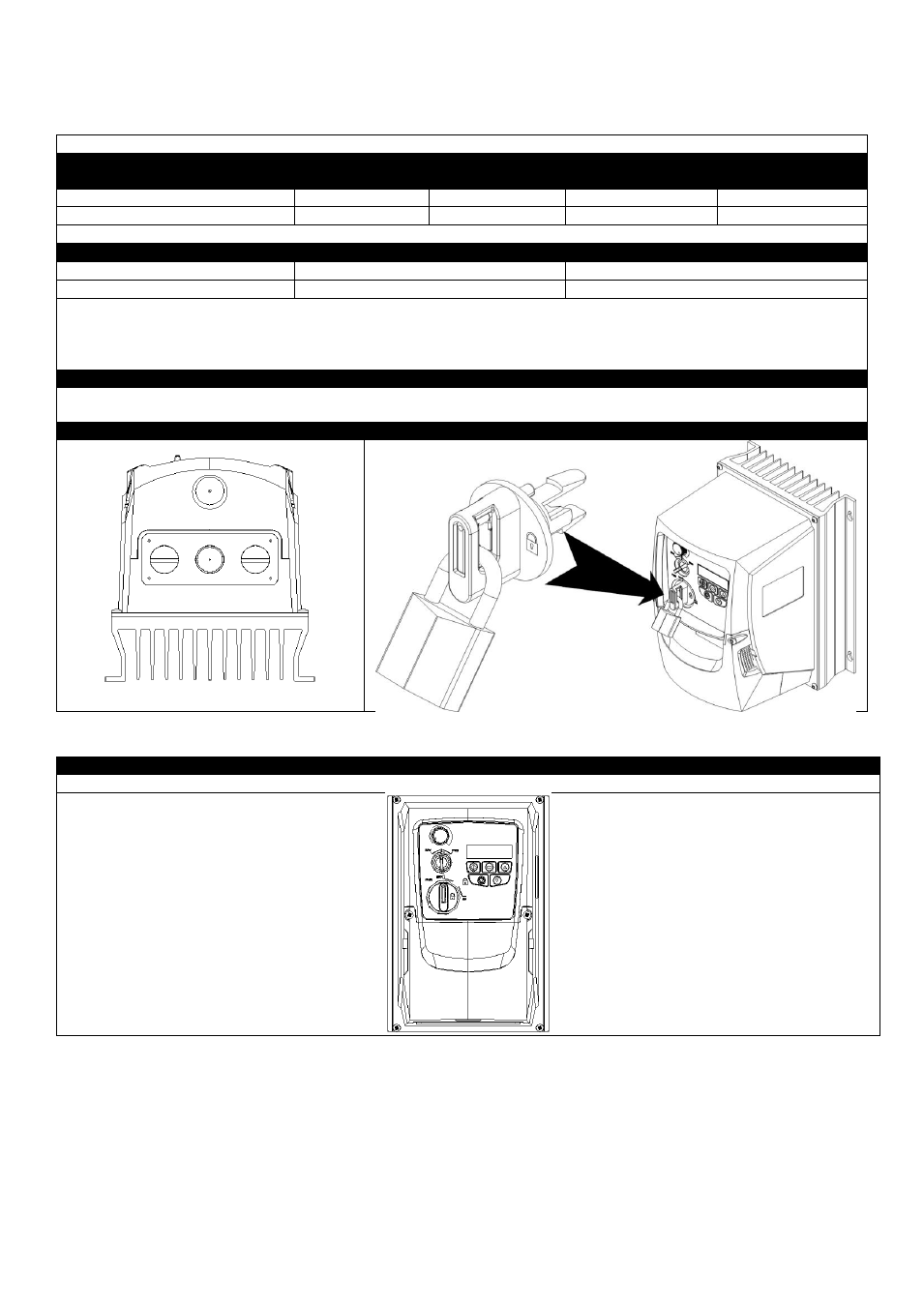

Power Isolator Lock Off

On the switched models the main power isolator switch can be locked in the ‘Off’ position using a 20mm standard shackle padlock (not

supplied).

IP66 / Nema 4X Gland Plate

IP66 / Nema 4X Unit Lock Off

3.9. Removing the Terminal Cover

To access the connection terminals, the drive front cover needs to be removed as shown.

IP66 / Nema 4X Units

Removing the 2 screws on the front of the product allows access to the connection terminals, as shown below.

3.10. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating environment,

this should include:

Ambient temperature is at or below that set out in the “Environment” section.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables have no signs

of heat damage.