Modbus rtu communications, Introduction, Modbus rtu specification – Beijer Electronics Industrial Inverter E2 User Manual

Page 27: Rj45 connector configuration, Modbus telegram structure, Modbus register map

27

8. Modbus RTU Communications

8.1. Introduction

The drive can be connected to a Modbus RTU network via the RJ45 connector on the front of the drive.

8.2. Modbus RTU Specification

Protocol

Modbus RTU

Error check

CRC

Baud rate

9600bps, 19200bps, 38400bps, 57600bps, 115200bps (default)

Data format

1 start bit, 8 data bits, 1 stop bits, no parity.

Physical signal

RS 485 (2-wire)

User interface

RJ45 (see section 5.2 for more information)

8.3.

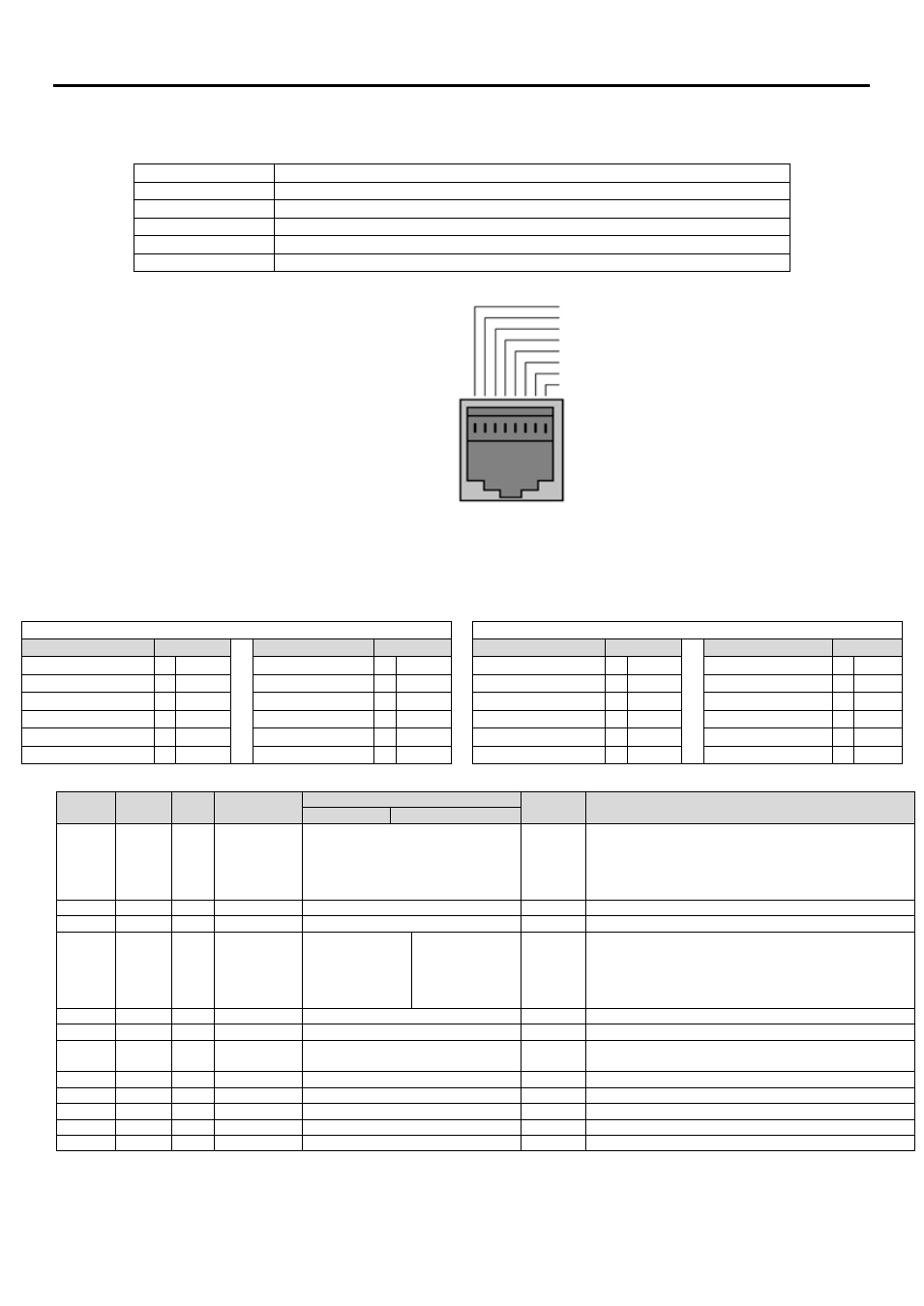

RJ45 Connector Configuration

For full MODBUS RTU register map

information please refer to Beijer Electronics.

When using MODBUS control the Analog and

Digital Inputs

can be configured as shown in section 7.3

1

No Connection

2

No Connection

3

0 Volts

4

-RS485 (PC)

5

+RS485 (PC)

6

+24 Volt

7

-RS485 (Modbus RTU)

8

+RS485 (Modbus RTU)

Warning:

This is not an Ethernet

connection. Do not connect

directly to an Ethernet port.

8.4. Modbus Telegram Structure

The drive supports Master / Slave Modbus RTU communications, using the 03 Read Holding Registers and 06 Write Single Holding Register

commands. Many Master devices treat the first Register address as Register 0, therefore it may be necessary to convert the Register Numbers

detail in section 8.5 by subtracting 1 to obtain the correct Register address. The telegram structure is as follows:-

Command 03 – Read Holding Registers

Command 06 – Write Single Holding Register

Master Telegram

Length

Slave Response

Length

Master Telegram

Length

Slave Response

Length

Slave Address

1 Byte

Slave Address

1 Byte

Slave Address

1 Byte

Slave Address

1 Byte

Function Code (03)

1 Byte

Starting Address

1 Byte

Function Code (06)

1 Byte

Function Code (06)

1 Byte

1

st

Register Address

2 Bytes

1

st

Register Value

2 Bytes

Register Address

2 Bytes

Register Address

2 Bytes

No. Of Registers

2 Bytes

2

nd

Register Value

2 Bytes

Value

2 Bytes

Register Value

2 Bytes

CRC Checksum

2 Bytes

Etc...

CRC Checksum

2 Bytes

CRC Checksum

2 Bytes

CRC Checksum

2 Bytes

8.5.

Modbus Register Map

Register

Number

Par.

Type

Supported

Commands

Function

Range

Explanation

Low Byte

High Byte

1

-

R/W

03,06

Drive Control Command

0..3

16 Bit Word.

Bit 0 : Low = Stop, High = Run Enable

Bit 1 : Low = Decel Ramp 1 (P-04), High = Decel Ramp 2 (P-24)

Bit 2 : Low = No Function, High = Fault Reset

Bit 3 : Low – No Function, High = Coast Stop Request

2

-

R/W

03,06

Modbus Speed reference setpoint

0..5000

Setpoint frequency x10, e.g. 100 = 10.0Hz

4

-

R/W

03,06

Acceleration and Deceleration Time

0..60000

Ramp time in seconds x 100, e.g. 250 = 2.5 seconds

6

-

R

03

Error code

Drive status

Low Byte = Drive Error Code, see section 10.1

High Byte = Drive Status as follows :-

0 : Drive Stopped

1: Drive Running

2: Drive Tripped

7

R

03

Output Motor Frequency

0..20000

Output frequency in Hz x10, e.g. 100 = 10.0Hz

8

R

03

Output Motor Current

0..480

Output Motor Current in Amps x10, e.g. 10 = 1.0 Amps

11

-

R

03

Digital input status

0..15

Indicates the status of the 4 digital inputs

Lowest Bit = 1 Input 1

20

P00-01

R

03

Analog Input 1 value

0..1000

Analog input % of full scale x10, e.g. 1000 = 100%

21

P00-02

R

03

Analog Input 2 value

0..1000

Analog input % of full scale x10, e.g. 1000 = 100%

22

P00-03

R

03

Speed Reference Value

0..1000

Displays the setpoint frequency x10, e.g. 100 = 10.0Hz

23

P00-08

R

03

DC bus voltage

0..1000

DC Bus Voltage in Volts

24

P00-09

R

03

Drive temperature

0..100

Drive heatsink temperature in ºC

All user configurable parameters are accessible as Holding Registers, and can be Read from or Written to using the appropriate Modbus

command. The Register number for each parameter P-04 to P-047 is defined as 128 + Parameter number, e.g. for parameter P-15, the register

number is 128 + 15 = 143. Internal scaling is used on some parameters, for further details, please contact Beijer Electronics.