E 10, Guidelines for mounting enclosed units – Beijer Electronics Industrial Inverter E2 User Manual

Page 10

10

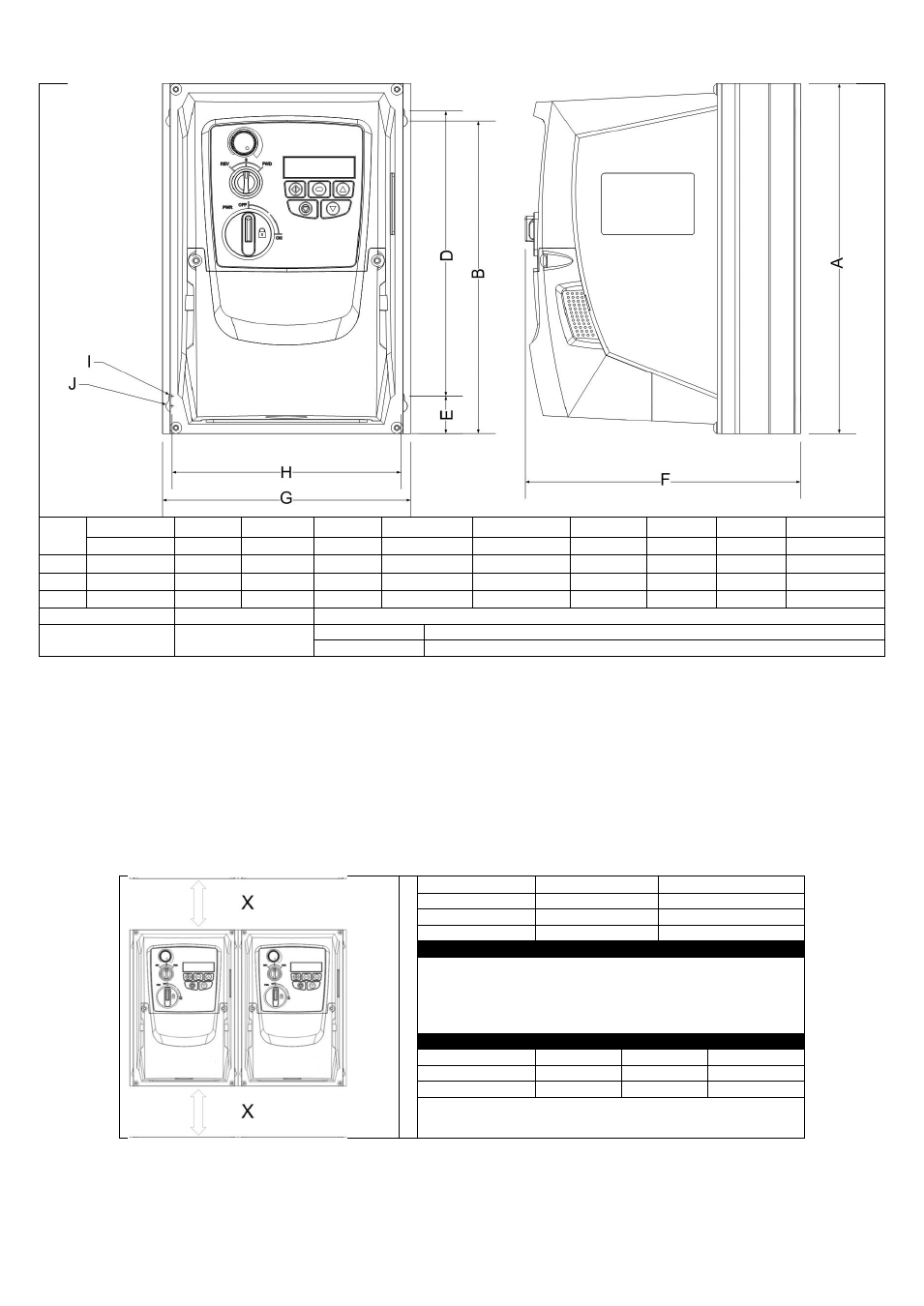

3.6. Mechanical Dimensions – IP66 (Nema 4X) Enclosed Units

Drive

Size

A / Height

B

D

E

F / Depth

G / Width

H

I

J

Weight

mm

mm

mm

mm

mm

mm

mm

mm

mm

kg

1

232.0

207.0

189.0

25.0

179.0

161.0

148.5

4.0

8.0

3

2

257.0

220.0

200.0

28.5

186.5

188.0

176.0

4.2

8.5

4,2

3

310.0

276.5

251.5

33.4

228.7

210.5

197.5

4.2

8.5

7,7

Mounting Bolts

All Frame Sizes

4 x M4

Tightening Torques

All Frame Sizes

Control Terminals

0.5 Nm

Power Terminals

1 Nm

3.7. Guidelines for Mounting Enclosed Units

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 9.1

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

Using the drive as a template, or the dimensions shown below, mark the locations required for drilling

Suitable cable glands to maintain the ingress protection of the drive are required. Gland holes for power and motor cables are pre-

moulded into the drive enclosure, recommended gland sizes are shown above. Gland holes for control cables may be cut as required

Drive Size

X Above & Below

Y Either Side

mm

mm

2

200

10

3

200

10

Note :

Typical drive heat losses are approximately 3% of operating load

conditions.

Above are guidelines only and the operating ambient temperature of the

drive MUST be maintained at all times.

Cable Gland Sizes

Frame

Power Cable

Motor Cable

Control Cables

2

M25 (PG21)

M25 (PG21)

M20 (PG13.5)

3

M25 (PG21)

M25 (PG21)

M20 (PG13.5)