Pulsation dampener removal, Diaphragm back pressure and pressure relief valves, Diaphragm back pressure valve – Pulsafeeder Pulsar Shadow User Manual

Page 44: 3 pulsation dampener removal

13.3 Pulsation Dampener Removal

When removing or disassembling a pulsation dampener, drain all piping and remove all air and

process pressure. Assume that the diaphragm is broken and the chamber is flooded under

pressure since the pressure gauge could be damaged. Separate chambers with caution in a

direction away from the body.

R

EMEMBER THAT THE PULSATION DAMPENER HOUSING WILL RETAIN SOME AMOUNT OF

PROCESS FLUID

,

AND HANDLE ACCORDINGLY

.

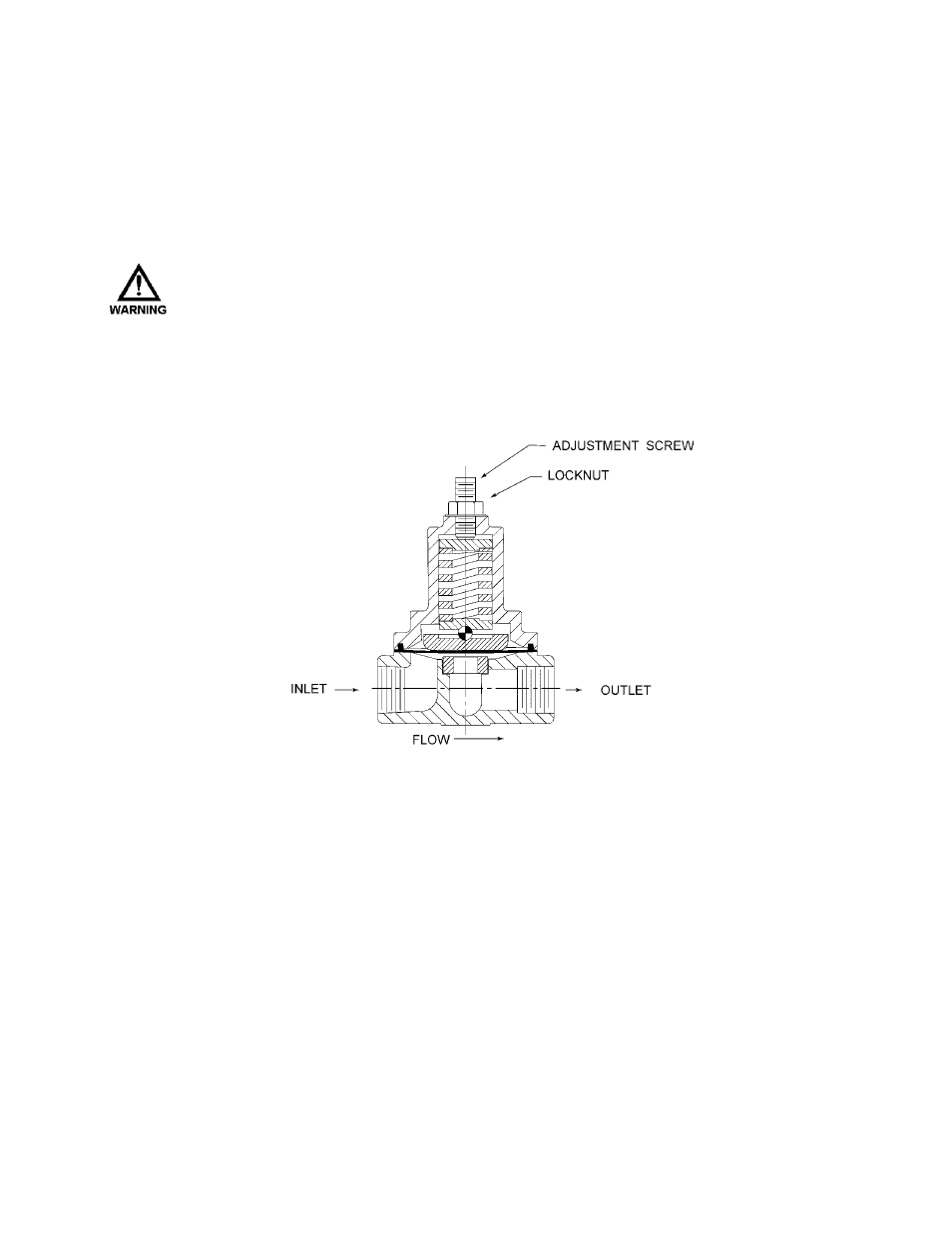

13.4 Diaphragm Back Pressure and Pressure Relief Valves

Figure 24

A diaphragm backpressure valve creates a constant system backpressure upstream of the valve.

A TFE diaphragm, offering maximum chemical protection and service life, seals the spring and

bonnet from the product. This diaphragm seals directly on a replaceable seat. In most systems,

the setting of the backpressure valve will determine the overall system backpressure seen by the

metering pump.

A diaphragm pressure relief valve protects system components from excessive pressure within

the system. The valve is normally set to some value slightly above normal process pressure. If

this pressure setting is exceeded, the pressure relief valve will open to control and limit system

pressure. The outlet port of the pressure relief valve should be carefully directed back to the

supply tank or to some other safe point. The use of a pressure relief valve is especially

important in systems utilizing mechanical diaphragm pumps, as these pumps have no internal

bypass or relief capability.

Be sure to install either type of valve with fluid flow in direction of arrow on valve body or

label.

38