Calibration, 3 calibration – Pulsafeeder Pulsar Shadow User Manual

Page 23

4. Start the pump at the zero stroke length setting and slowly increase the setting to 100 to prime

the pump. If this does not work, it will be necessary to fill the suction line.

5. Filling of the suction line will necessitate the use of a foot valve or similar device at the end

of the suction line so that liquid can be maintained above the reservoir level. Remove the

suction valve assembly, fill the line, replace the valve, then remove the discharge valve

assembly and fill the reagent head as described in Step (3) above. The pump will now self-

prime when started up per step (4) above.

6.3

Calibration

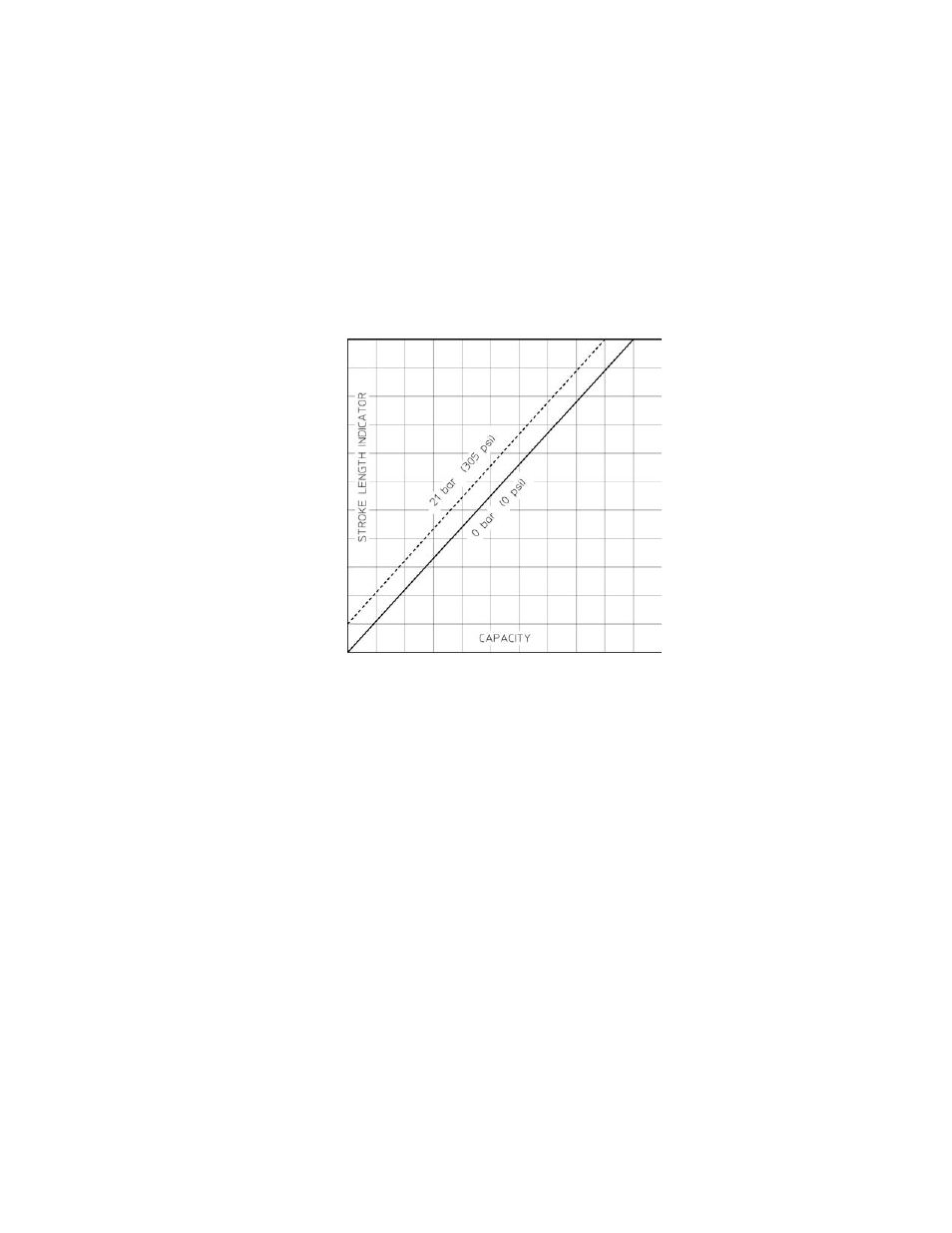

Figure 14

All metering pumps must be calibrated in order to accurately specify stroke length settings for

required flow rates. For pumps provided with DLC/M electronic controls, refer to separate

instructions provided with those controllers.

A typical calibration chart is shown in Figure 14. Although output is linear with respect to stroke

length setting, an increase in discharge pressure decreases output uniformly, describing a series of

parallel lines, one for each pressure (only two are shown).

The theoretical output flow rate at atmospheric discharge pressure is based on the displacement of

the diaphragm, stroke length and the stroking rate of the pump. With increasing discharge

pressure there is a some corresponding decrease in output flow. Pumps are rated at a certain flow

at their rated pressure (check nameplate). Whenever possible, calibration should be performed

under actual process conditions (i.e., the same or a similar process liquid at system operating

pressure).

To construct a calibration chart, measure the flow rate several times at three or more stroke

settings (i.e., 25, 50, 75, and 100), plot these values on linear graph paper, and draw a best-fit line

through the points. For stable conditions, this line should predict settings to attain required

outputs.

17