Standard diaphragm, 1 standard diaphragm – Pulsafeeder Pulsar Shadow User Manual

Page 26

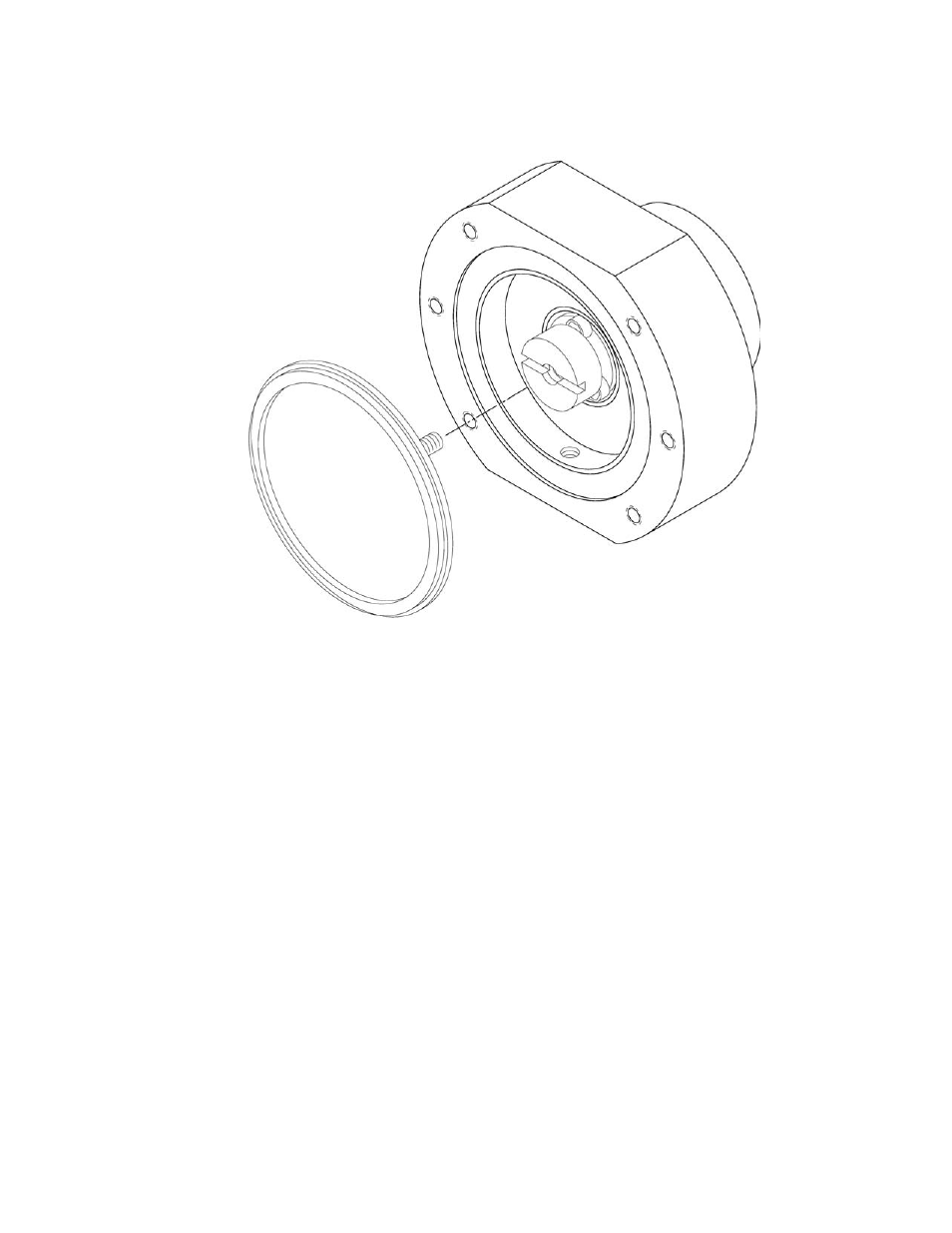

7.1.1 Standard

Diaphragm

Figure 16

PULSAR Shadow

®

diaphragms do not have a specific cycle life; however, the accumulation of

foreign material or debris sufficient to deform the diaphragm can eventually cause failure.

Failure can also occur as a result of system over pressure or chemical attack. Periodic diaphragm

inspection and replacement are recommended.

1. Adjust the stroke setting to 50 percent and disconnect the power source to the drive motor

2. Relieve all pressure from the piping system.

3. Take all precautions described in this manual to prevent environmental and personnel

exposure to hazardous materials.

4. Close the inlet and outlet shutoff valves.

5. Disconnect piping to the reagent head and drain any process liquid, following material safety

precautions described. Removal of the check valves may assist in this process.

6. Place a pan underneath the pump head adaptor to catch any liquid leakage.

7. Remove all but one top reagent head bolt. Product will leak out between the pump head

adaptor and reagent head as the bolts are loosened.

8. Tilt the head and pour out any liquids retained into a suitable container, continuing to follow

safety precautions as appropriate.

20