Installation, Location, Piping system – Pulsafeeder Pulsar Shadow User Manual

Page 14: Nstallation, 1 location, 2 piping system

4. Installation

4.1 Location

When selecting an installation site or designing a skid package, consideration should be given to

access for routine maintenance.

PULSAR Shadow

®

pumps are designed to operate indoors and outdoors, but it is desirable to

provide a hood or covering for outdoor service. External heating is required if ambient

temperatures below 0

O

C (32

O

F) are anticipated. Check with the factory if concerned with the

suitability of the operating environment.

The pump must be rigidly bolted to a solid and flat foundation to minimize vibration, which can

loosen connections. When the pump is bolted down, care must be taken to avoid distorting the

base and affecting alignments. The pump must be level within 5

O

. This will assure that the

eccentric and gear oils are maintained at the proper levels and that the check valves can operate

properly.

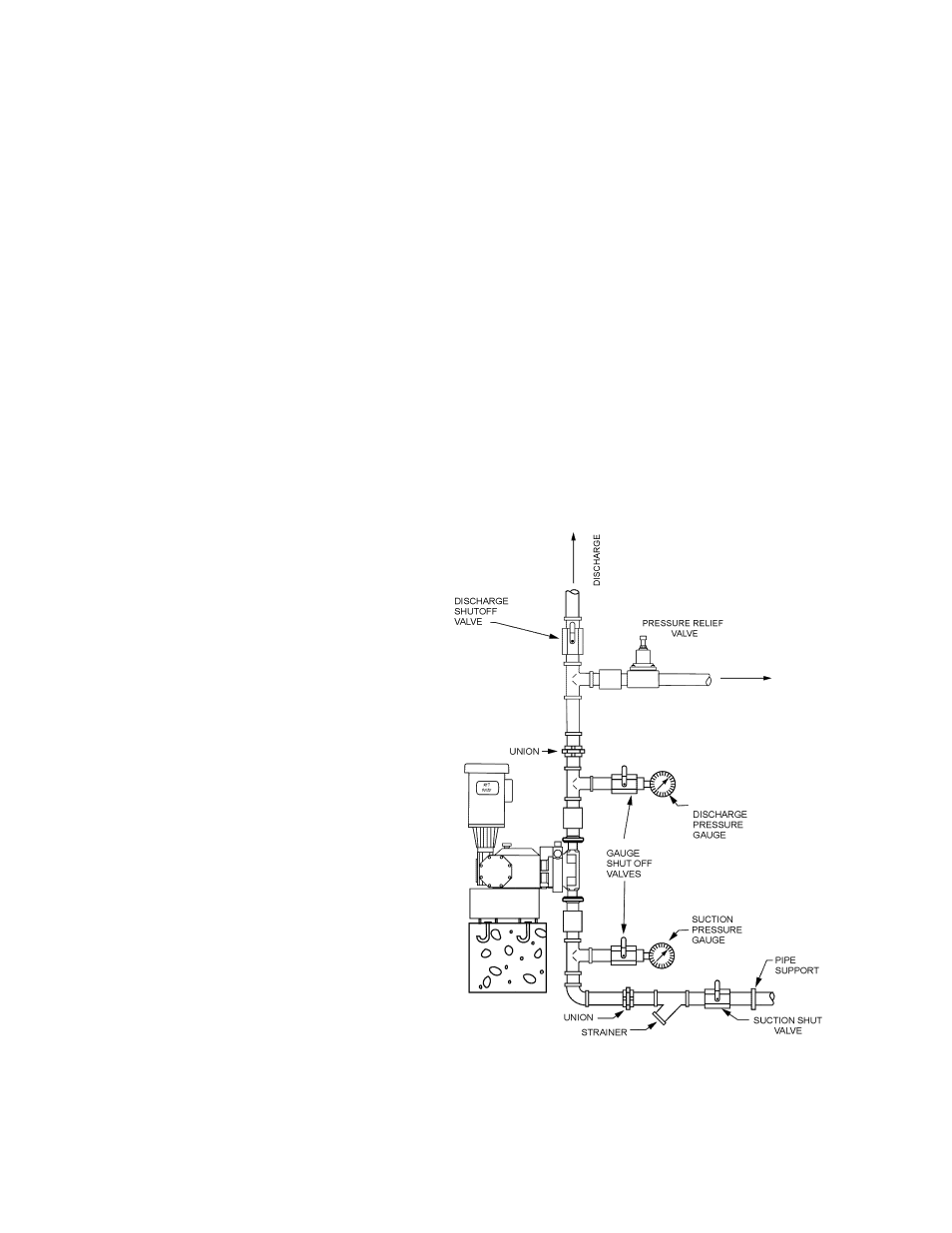

4.2 Piping

System

All piping systems should include:

1. A separate system relief valve to

protect piping and process

equipment, including the pump,

from excess process pressures.

*An external relief valve is

required, as a mechanical

diaphragm pump does not

incorporate an internal relief.

2. Shutoff valves and unions (or

flanges) on suction and discharge

piping. This permits check valve

inspection without draining long

runs of piping. Shutoff valves

should be of the same size as

connecting pipe. Ball valves are

preferred since they offer

minimum flow restriction.

Figure 8

8