Troubleshooting, Propeller and shaft replacement precautions – COOK Propeller Upblast User Manual

Page 6

6

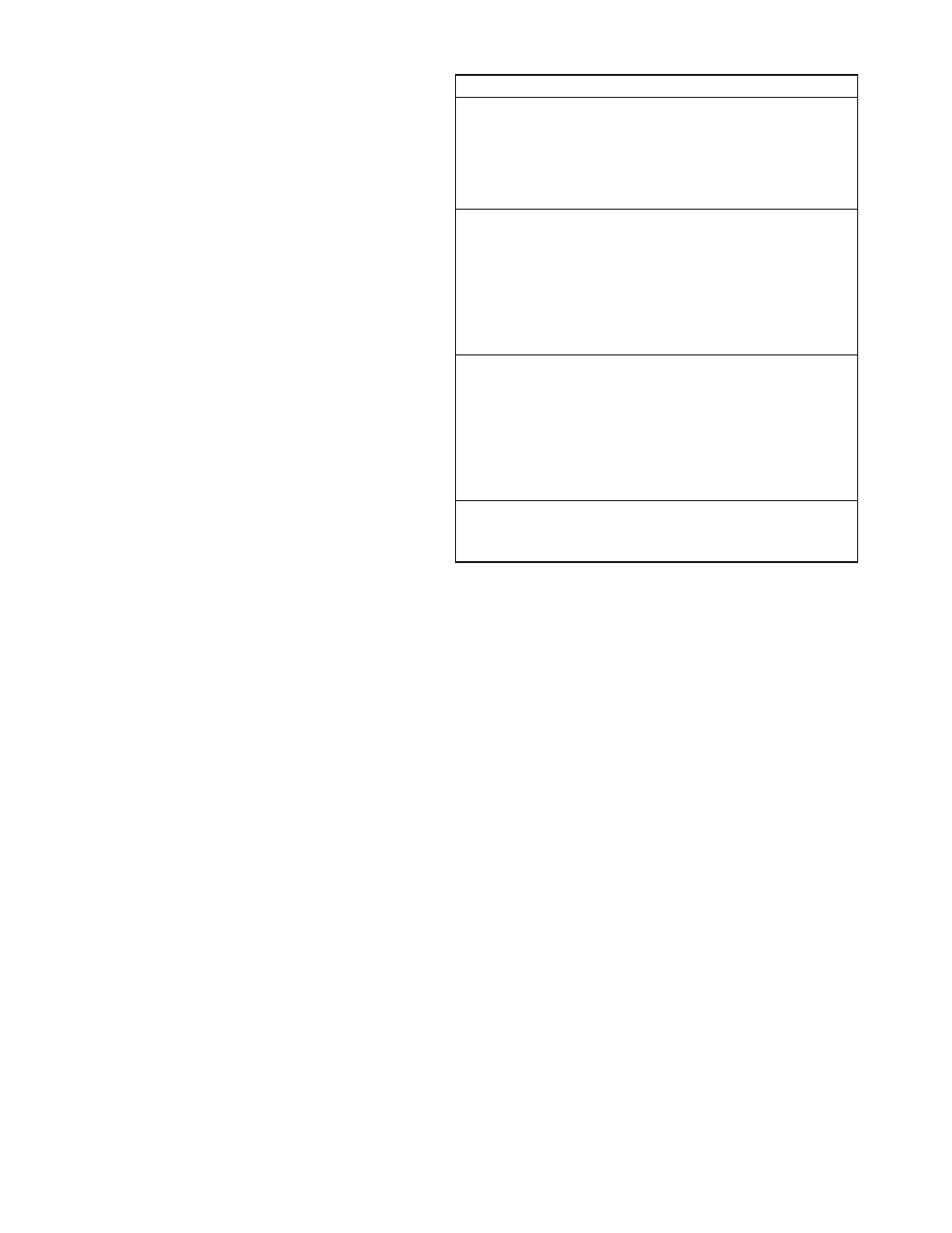

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at the

inlet.

•Improper propeller alignment.

Excessive Vibration and Noise

•Damaged or unbalanced propeller.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same di-

rection as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.

g. Remove the bearing from the shaft using a bearing

puller.

h. Clean the shaft and bearing bores thoroghly.

i. Place the bearings into position making sure they are

not on a worn section of the shaft. Tapping the inner

ring face with a soft driver may be required. Tighten the

setscrews on the lower bearing.

j. Install the pulley in the correct location on the shaft.

Secure the bearing hold-down bolts, but do not fully

tighten.

k. Align the setscrews on the top bearing with those on

the lower bearing. Tighten one of them.

l. Rotate the shaft to allow the bearing outer rings to find

their center of free movement. If your fan is supplied

with a lube line, attach it to the grease connection.

m. Install the propeller on the shaft and adjust bearing

position to center the propeller in the opening.

n. Tighten hold-down bolts to proper torque. Refer to the

Torque Chart on page 4.

o. Turn the shaft by hand. Resistance should be the same

as it was before hold-down bolts were fully tightened.

p. Tighten bearing setscrews to specified torque.

r. Reassembly the fan.

After 24 hours of continuous operation, tighten the set-

screws to the appropriate torque. This assures the full lock-

ing of the inner race to the shaft. Ensure the socket key or

driver is in good condition with no rounded corners. The

key should be fully engaged in the setscrew and held

squarely to prevent the rounding out of the setscrew socket

when applying maximum torque.

Propeller and Shaft Replacement Precautions

• If the shaft is dropped and bent, it may cause unbal-

anced operation of the fan.

• When handling the propeller separately from the shaft,

place a support through the hub for lifting, making sure

not to injure the finished bore of the propeller.

• Never allow the propeller to rest its entire weight on the

blades. The propeller and shaft can be lifted by slings

around the shaft on each side of the propeller so the

propeller is supported by its hub.

• If using a chain to lift the propeller, make sure there is

sufficient padding on the shaft and propeller. This pre-

vents the scoring of the shaft or injury to the propeller.

The chain or cable should be spread with timbers, or

braced by some other method to prevent damage to

the propeller side plates.