Motor bearings, Fan bearings, Motor services – COOK Propeller Upblast User Manual

Page 5: Changing shaft speed, Pulley and belt replacement, Bearing replacement, Maximum rpm

5

grades of grease should not be used unless the bearings

and lines have been flushed clean. If another grade of

grease is used, it should be lithium-based.

A NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its tempera-

ture range is from -30

F to +200F and capable of intermit-

tent highs of +250

F.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under nor-

mal conditions they will not require further maintenance for

a period of ten years. However, it is advisable to have your

maintenance department remove and disassemble the

motor, and lubricate the bearings after three years of oper-

ation in excessive heat and or in a contaminated airstream

consisting of airborne abrasives.

Fan Bearings

Fan bearings are lubricated through a grease connector

and should be lubricated by the schedule, Conditions

Chart, on page 4.

For best results, lubricate the bearing while the fan is

rotating. Slowly pump grease into the bearing until a slight

bead forms around the bearing seals. Excessive grease

can burst seals thus reduce bearing life.

In the event the bearing cannot be seen, use no more

than three injections with a hand-operated grease gun.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Changing Shaft Speed

All belt driven propeller roof fans with motors up to and

including 5HP are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are main-

tained.

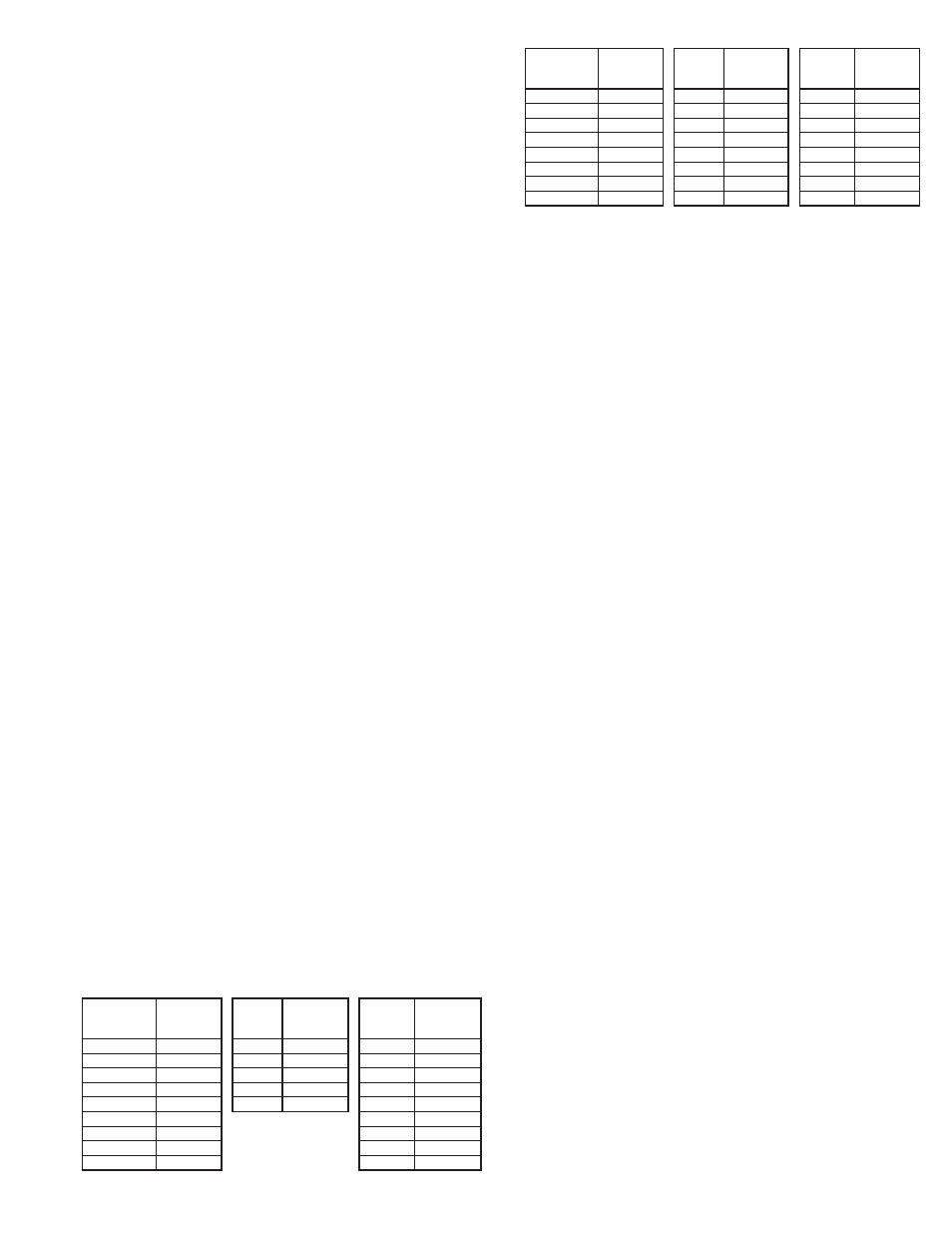

Maximum RPM

TUB, SUB,

SUBH

Size

Maximum

RPM

AUB

Maximum

RPM

EUB

Maximum

RPM

20

2633

24

1585

24

1650

24

1993

30

1180

30

1305

30

1605

36

1015

36

1305

36

1314

42

935

42

1200

42

1106

48

845

48

1150

48

973

54

900

54

888

60

870

60

783

72

688

72

616

Maximum RPM

TUB, SUB,

SUBH

Size

Maximum

RPM

AUB

Maximum

RPM

EUB

Maximum

RPM

20

2633

24

1585

24

1650

24

1993

30

1180

30

1305

30

1605

36

1015

36

1305

36

1314

42

935

42

1200

42

1106

48

845

48

1150

48

973

54

900

54

888

60

870

60

783

72

688

72

616

Maximum RPM

TUB, SUB,

SUBH

Size

Maximum

RPM

AUB

Maximum

RPM

EUB

Maximum

RPM

20

2633

24

1585

24

1650

24

1993

30

1180

30

1305

30

1605

36

1015

36

1305

36

1314

42

935

42

1200

42

1106

48

845

48

1150

48

973

54

900

54

888

60

870

60

783

72

688

72

616

Maximum RPM

LXUL

Size

Maximum

RPM

LXUM Maximum

RPM

LEU

Maximum

RPM

20

1270

20

1460

20

1675

24

1110

24

1400

24

1650

30

930

30

1170

30

1350

36

720

36

860

36

1310

42

600

42

718

42

1210

48

508

48

598

48

1214

54

478

54

522

54

946

60

450

60

476

60

854

Pulley and Belt Replacement

a. Clean the motor and fan shafts.

b. Loosen the motor plate mounting bolts to relieve the

belt tension. Remove the belt.

c. Loosen the pulley setscrews and remove the pulleys

from the shaft.

If excessive force is required to remove the pulleys, a

three-jaw puller can be used. This tool, however,

can easily warp a pulley. If the puller is used,

inspect the trueness of the pulley after it is

removed from the shaft. The pulley will need

replacement if it is more than 0.020 inch out of

true.

d. Clean the bores of the pulleys and place a light coat of

oil on the bores.

e. Remove grease, rust and burrs from the shaft.

f. Place fan pulley on the fan shaft and the motor pulley on

the motor shaft. Damage to the pulleys can occur when

excessive force is used in placing the pulleys on their

respective shafts.

g. After the pulleys have been correctly placed back onto

their shafts, tighten the pulley setscrews.

h. Install the belts on the pulleys. Align and adjust the

belts to the proper tension as described in Belt and Pul-

ley Installation, page 2.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Remove the wind band and damper assembly to gain

access to the fan.

b. Loosen the motor plate mounting bolts and remove the

drive belts.

c. Remove the propeller from the shaft.

d. Remove the bearing cover. Remove the four (4) bear-

ing hold-down bolts and then remove the shaft, bear-

ings, and driven sheave from the unit as an assembly.

e. Measure and record the location of the bearings and

sheave on the shaft. This will aid the reassembly.

f. Remove the anti-corrosion coating from the shaft with a

suitable degreaser and then remove the pulley from the

shaft. An emery cloth or file may be needed to remove

imperfections in the shaft left by the setscrews.