Operation, Inspection, Maintenance – COOK Propeller Upblast User Manual

Page 4: Lubricants

4

TUB

/

SUB

/

SUBH Additional Installation Steps

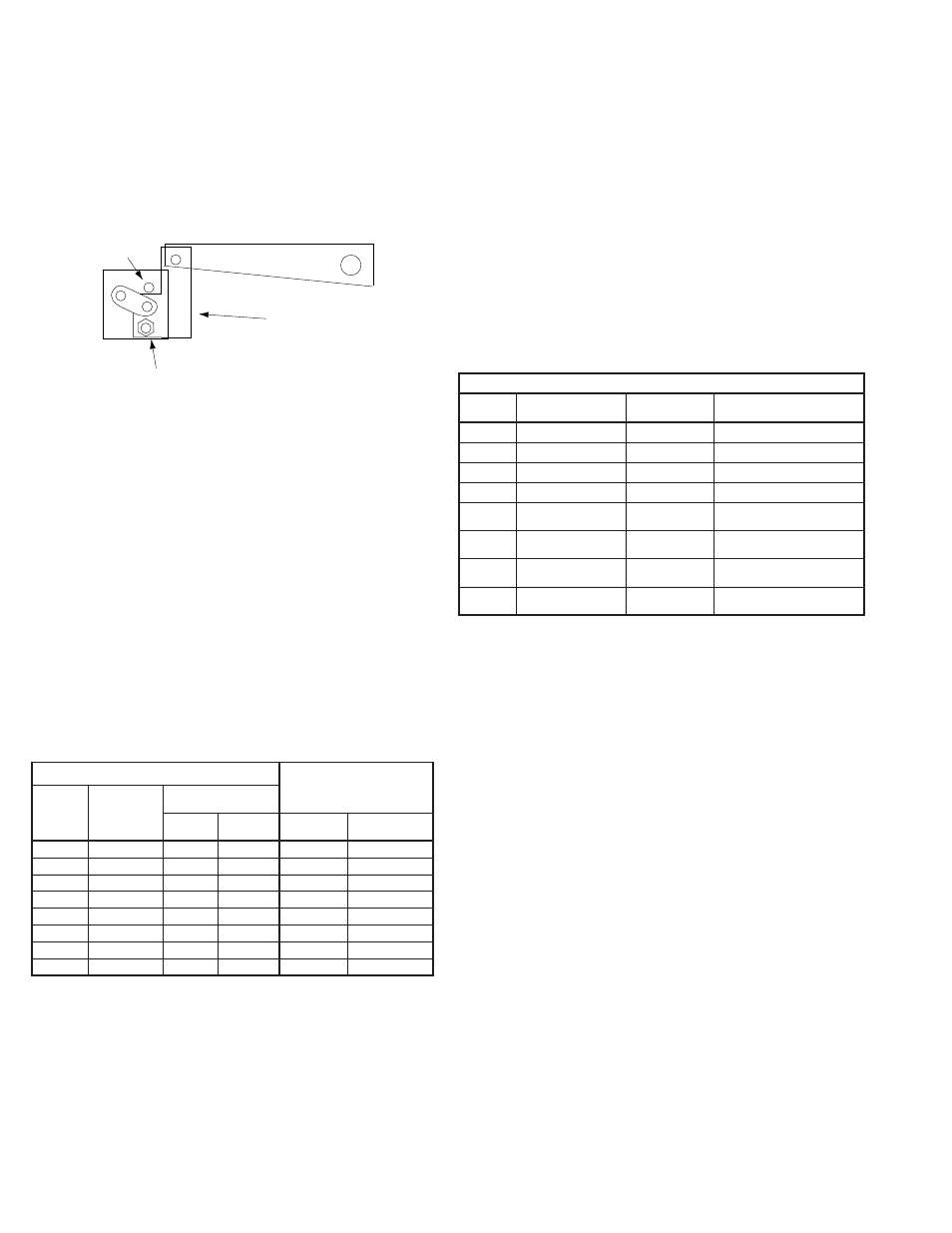

The damper actuator arms are safety bolted at the factory

to prevent damage or personnel injury during handling and

installation. The bolt must be removed for the damper actu-

ator to operate correctly. Refer to Figure 4.

• Remove Bolt “A” from each of the damper arms.

• Be sure that linkage hook “B” is in contact with bolt “C” to

prevent excessive load on the fusible link.

The damper arms will not operate unless this bolt is

removed. This bolt should be replaced before any mainte-

nance or repair work is started.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Inspect fasteners and setscrews, particularly those

used for mounting the unit, and tighten if necessary.

c. Inspect belt tension and pulley alignment. (Remember,

if belt tension is correct, a loud squeal occurs as the fan

increases to full power.)

d. Inspect motor wiring.

e. Ensure the belt touches only the pulleys.

f. Rotate the propeller to ensure it does not rub against the

base.

g. Ensure fan and ductwork are clean and free of debris.

h. Test the fan to ensure the rotation of the propeller is the

same as indicated by the rotation label.

i. Close and secure all access doors.

j. Restore power to unit.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for a continu-

ous squealing noise).

Bolt C

Linkage

Bolt A

Figure 4 - SUBH Safety Bolt Removal

Hook B

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”- 9

2040

1/2”

1/4”

504

600

1”- 8

3000

5/8”

5/16”

1104

1200

1-1/8” - 7

4200

3/4”

3/8”

1440

1800

1-1/4” - 7

6000

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut off the

fan. Lock out all electrical power and check for the

cause of the trouble. Refer to Troubleshooting, page 6.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the chart below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating con-

ditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting con-

taminated air (airborne abrasives) should be inspected

every three months. Clean the propeller and air inlets if

material build-up is excessive. Excessive build-up can

cause imbalance and failure of the propeller.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

Belt and Pulley Installation, page 2.

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

Lubricants

Loren Cook Company uses petroleum lubricant in a lith-

ium base conforming to NLGI grade 2 consistency. Other

Conditions Chart

RPM

Temperature

Fan

Status

Greasing

Interval

100

Up to 120°F

Clean

6 to 12 months

500

Up to 150°F

Clean

2 to 6 months

1000

Up to 210°F

Clean

2 weeks to 2 months

1500 Over

210°F

Clean

Weekly

Any

Speed

Up to 150°F

Dirty

1 week to 1 month

Any

Speed

Over 150°F

Dirty

Daily to 2 weeks

Any

Speed

Any Temperature

Very Dirty

Daily to 2 weeks

Any

Speed

Any Temperature

Extreme

Conditions

Daily to 2 weeks