Wiring diagrams, Final installation steps, Single speed, single phase motor – COOK Propeller Upblast User Manual

Page 3: Typical damper motor schematic

3

T-1

T-4

Ground B

L 2

L1

Ground A

Line

Wiring Diagrams

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Follow the wiring diagram in the disconnect switch

and the wiring diagram provided with the motor. Cor-

rectly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Fan Installation

The fan support (roof curb) should provide a level surface

for installation. If the roof is pitched more than 1/2:12, a

sloped curb must be used to correct for the incline. If the

unit is installed on a non-level surface, the damper door

pivot should be positioned perpendicular to the peak of the

roof. Consult factory for additional details.

a. Place fan over roof opening.

b. Secure the fan with lag scews, anchor bolts, or other

suitable fasteners.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in the table on page

4, Recommended Torque for Setscrews/Bolts .

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

d. Test the fan to be sure the rotation is the same as indi-

cated by the arrow marked Rotation.

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious dam-

age. For 3-phase motors, if the fan is running in the

wrong direction, check the control switch. It is possi-

ble to interchange two leads at this location so that the

fan is operating in the correct direction.

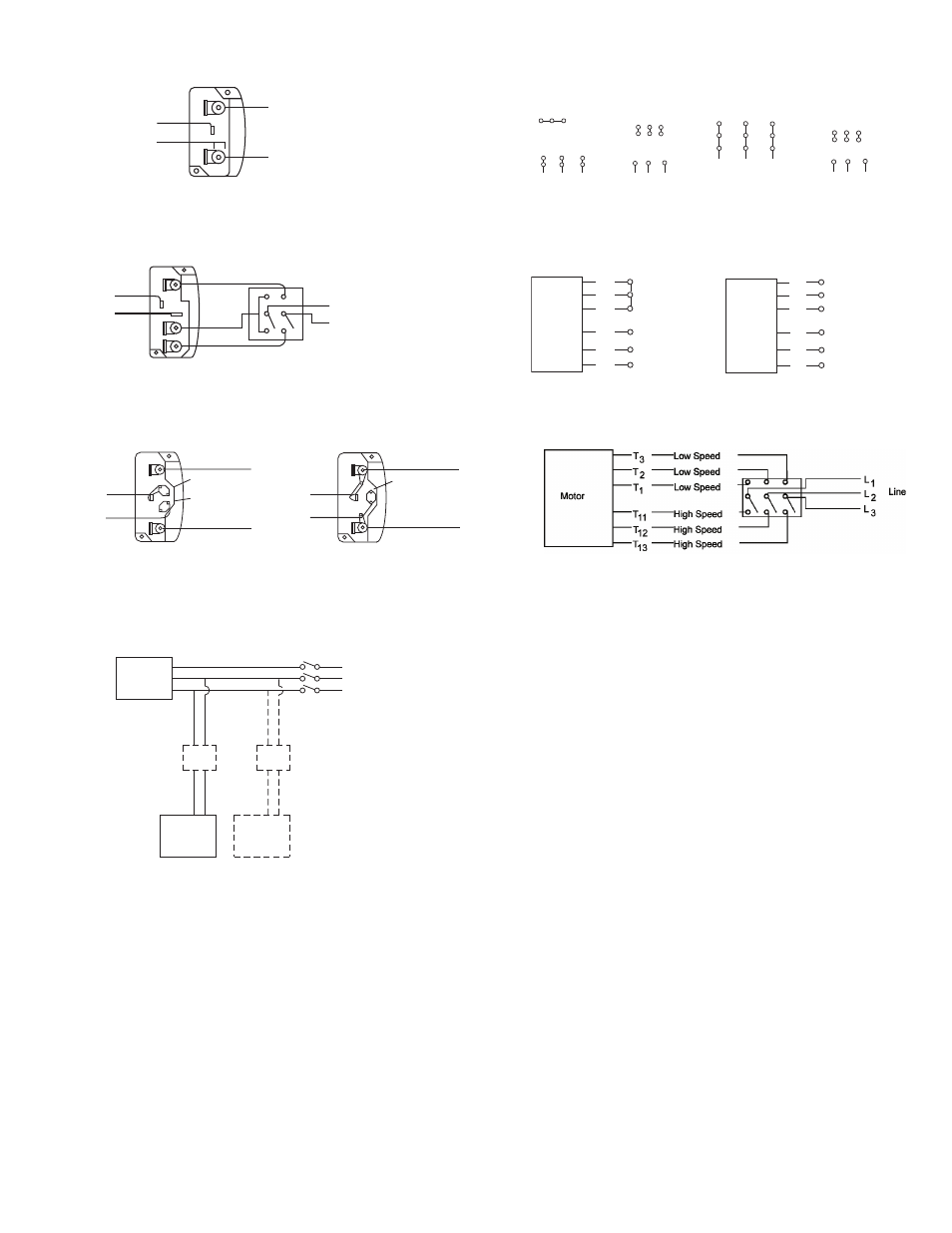

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be pro-

vided in some installations to correct the damper motor voltage to the

specified voltage.

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L1

L2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Motor

1

2

3

4

5

6

Together

High Speed

Line

L1

L2

L3

1

2

3

4

5

6

Open

Low Speed

Line

L1

L2

L3

Motor

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection