Installation – COOK Propeller Upblast User Manual

Page 2

2

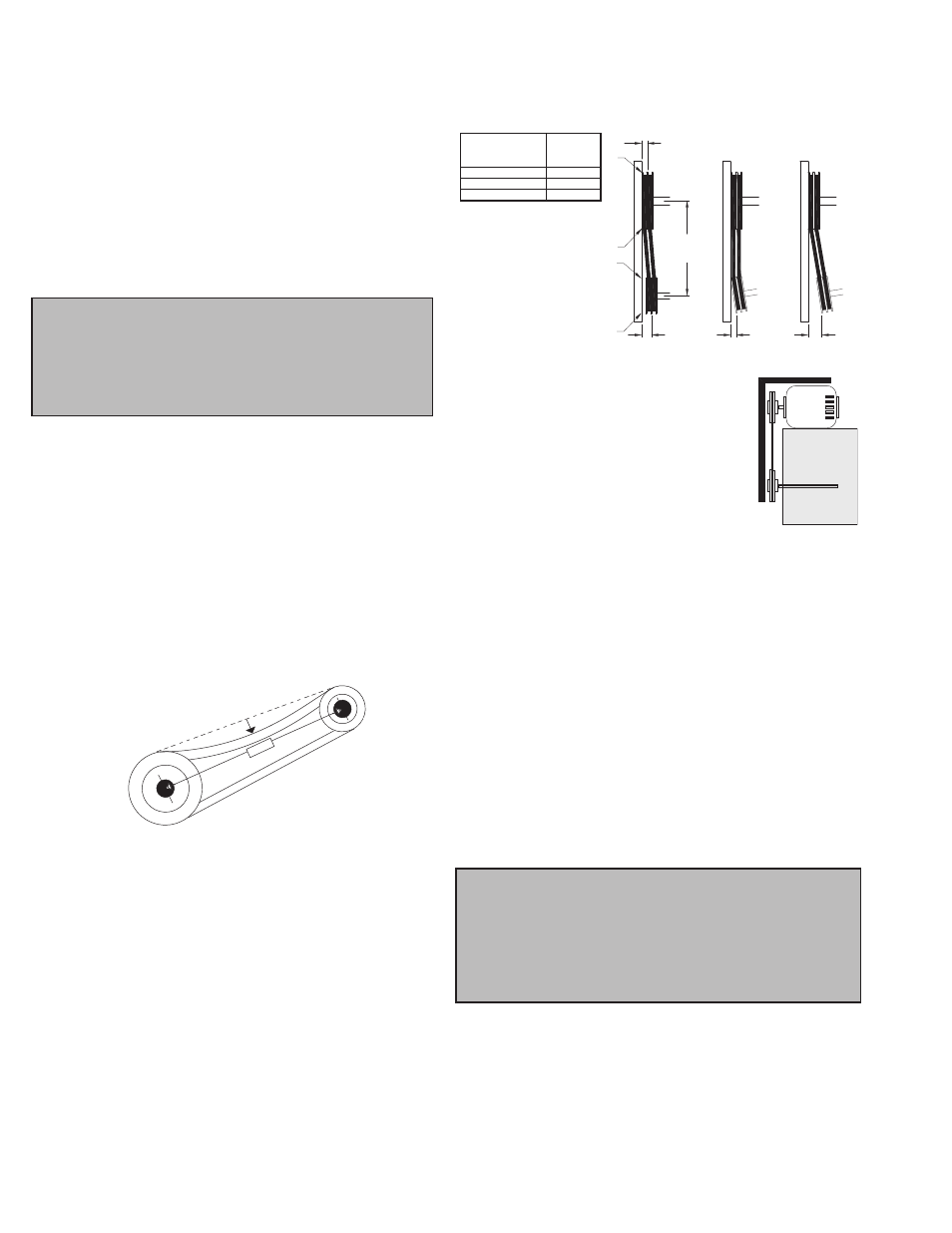

For proper tension, a deflection of approximately 1/4”

per foot of center distance should be obtained by firmly

pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

Pulley Alignment

Pulley alignment is adjusted by loosening

the motor pulley setscrew and by moving

the motor pulley on the motor shaft.

Figure 2 indicates where to measure the

allowable gap for the drive alignment toler-

ance. All contact points (indicated by

WXYZ) are to have a gap less than the tol-

erance shown in the table. When the pul-

leys are not the same width, the allowable

gap must be adjusted by half of the difference in width. Fig-

ure 3 illustrates using a carpenter’s square to adjust the

position of the motor pulley until the belt is parallel to the

longer leg of the square.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate. Refer to the Wiring Diagrams, on page 3.

Lock off all power sources before unit is wired to power

source.

Leave enough slack in the wiring to allow for motor move-

ment when adjusting belt tension. Some fractional motors

have to be removed in order to make the connection with

the terminal box at the end of the motor.

Tolerance

Center Distance

Maximum

Gap

Up thru 12”

1/16”

12” up through 48

1/8”

Over 48”

1/4”

OFFSET

ANGULAR

OFFSET/ANGULAR

A

W

X

Y

Z

B

CENTER

DISTANCE

(CD)

GAP

GAP

Figure 2

Personal Safety

Disconnect switches are recommended. Place the

disconnect switch near the fan in order that the

power can be swiftly cut off in case of an emer-

gency, and in order that maintenance personnel are

provided complete control of the power source.

Installation

Damper Installation

a. Place the damper inside the curb. Ensure the damper

will open freely for the correct direction of the airflow.

b. Secure to curb at the damper shelf by installing at least

two sheet metal screws (#10 x 1/2”) on each side of the

damper, through the tray, with the screw head catching

the flange on the damper. This will prevent the dampers

from lifting.

c. Drill a hole in the curb shelf for conduit needed for

motor wiring.

d. Operate the dampers manually to ensure the blades

move freely. Dampers should be released from full

open position to check for proper closing.

Motor Installation

To prevent damage to the fan during shipping, motors 5

HP and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be field mounted.

The motor should be mounted so that the motor plate is

between the fan shaft and motor shaft.

a. Remove the motor plate mounting bolts and the motor

plate.

b. Remove the motor mounting bolts from the motor plate.

c. Mount the motor to the motor plate aligning to the

appropriate holes.

d. Place the motor plate on the power assembly and rein-

stall the mounting bolts.

Belt and Pulley Installation

If your fan is a direct drive (model AUD), proceed to Wir-

ing Installation.

Belt tension is determined by the sound of the belts when

the fan is first started. The belts will produce a loud squeal,

which dissipates after the fan is operating at full capacity. If

belt tension is too tight or too loose, lost efficiency and

damage can occur.

Do not change the pulley pitch diameter to change ten-

sion. The change will result in a different fan speed.

a. Loosen the motor plate adjustment nuts on motor base

and move motor plate in order that the belts can easily

slip into the grooves on the pulleys. Never pry, roll, or

force the belts over the rim of the pulley.

b. Adjust the motor plate until proper tension is reached.

Note

An inlet basket guard is recommended. A basket

guard prevents any large debris from being pulled

into the fan and damaging the propeller. The Loren

Cook basket guard is installed on top of the curb

before the fan is installed.

1 foot

1/4 inch

Figure 1

Figure 3