Pulley and belt, Bearing, Wheel – COOK QMX User Manual

Page 7: Wheel replacement, Changing shaft speed, Pulley and belt replacement, Bearing replacement

7

k. Slide shaft through bearings until shaft protrudes the

same amount as measured above. Tapping the inner

race of each bearing with a soft driver may be

required. Do not hammer the end of the shaft or the

bearing housing.

l. Return setscrews to same location as marked above

and tighten one setscrew on each bearing to half its

specified torque.

m. Rotate the shaft to allow the bearings to align them

selves.

n. Replace wheel but do not tighten yet.

o. Replace inlet cone. Wheel may need to be moved to

allow proper alignment. Care should be taken to

insure that inlet cone is centered inside wheel before

and after tightening attaching bolts.

p. Slide wheel on shaft to achieve proper wheel/inlet

overlap and tighten wheel set screws. Refer to

Wheel-to-Inlet Clearance on page 3.

q. Tighten hold-down bolts to proper torque.

r. Turn the shaft by hand. resistance should be the

same as it was before hold-down bolts were fully tight-

ened.

s. Tighten all bearing setscrews to full specified torque.

t. Replace the sheave, align with motor sheave, and

adjust the belt tension.

u. Test run fan and retighten all setscrews and bolts, and

trim balance as necessary (.0785 in/sec max).

v. Replace discharge cover.

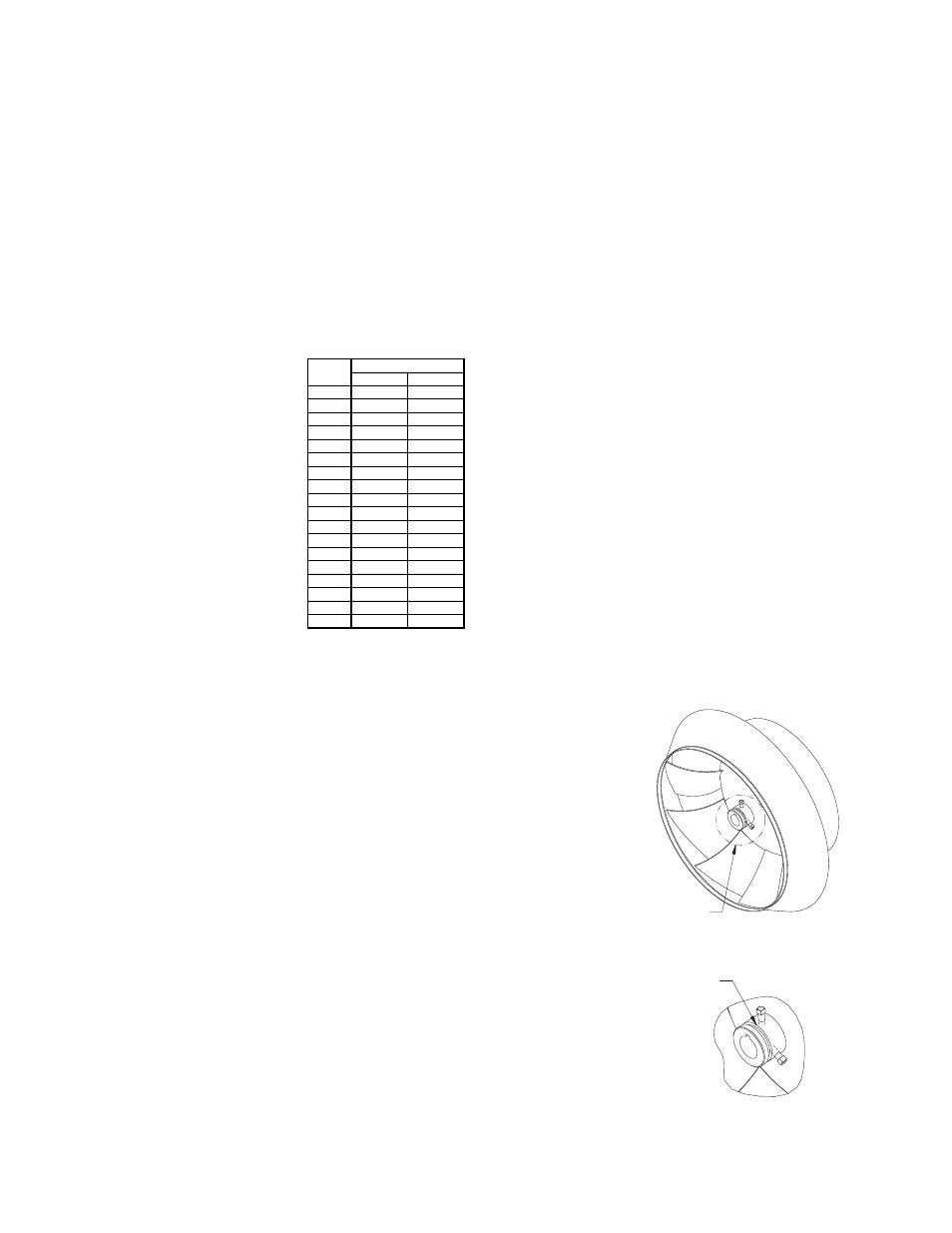

Wheel Replacement

The wheel has a pre-machined shoulder in the hub for

the use of most 2 and 3 jaw mechanical puller.

a. Align center of the puller with the center of the shaft.

b. Ensure all setscrews in the hub, normally two, are

fully removed.

c. Slowly remove wheel from the shaft.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in

the groove (larger pitch diameter). Ensure that the

speed limits of the fan and the horsepower limits of the

motor are maintained.

Pulley and Belt

Replacement

a. Loosen and remove belts

by adjusting motor

mounting plate.

b. Remove pulleys from

their respective shafts.

c. Clean the motor and fan

shafts.

d. Clean bores of pulleys

and coat the bores with

heavy oil.

e. Remove grease, rust, or

burrs from the pulleys

and shafts.

f. Remove burrs from shaft by sanding.

g. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

h. Tighten in place.

i. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Loosen and remove belts by adjusting motor mounting

plate

b. Remove the bearing cover by removing the bolts

around the perimeter of the bearing cover. Do not

remove fan sheave yet.

c. Remove inlet cone by removing attaching bolts/nuts

around perimeter of the inlet plate.

d. Remove wheel by loosening setscrews and sliding off

shaft.

e. Record the location of the fan sheave from end of

shaft, and remove the sheave.

f. Record the distance from the bearing to the end of the

shaft.

g. Loosen setscrews on bearings and remove shaft.

j. Remove bearings from bearing base and replace with

new ones, noting the exact location of each; do not

fully tighten base bolts.

SEE DETAIL A

PRE-MACHINED SHOULDER

DETAIL A

Fan

Size

Max Catalog RPM

QMX

QMX-HP

90

4943

5987

120

3707

4490

135

3295

3991

150

2907

3510

165

2633

3191

180

2423

2925

202

2152

2600

225

1937

2340

245

1780

2149

270

1623

1866

300

1465

1679

330

1332

1527

365

1207

1381

402

1081

1252

445

988

1132

490

897

1028

540

813

933

600

732

-