Typical wiring path for roof mounted units, Wheel rotation, Final steps – COOK QMX User Manual

Page 5: Operation, Start up, Inspection, Final installation steps

5

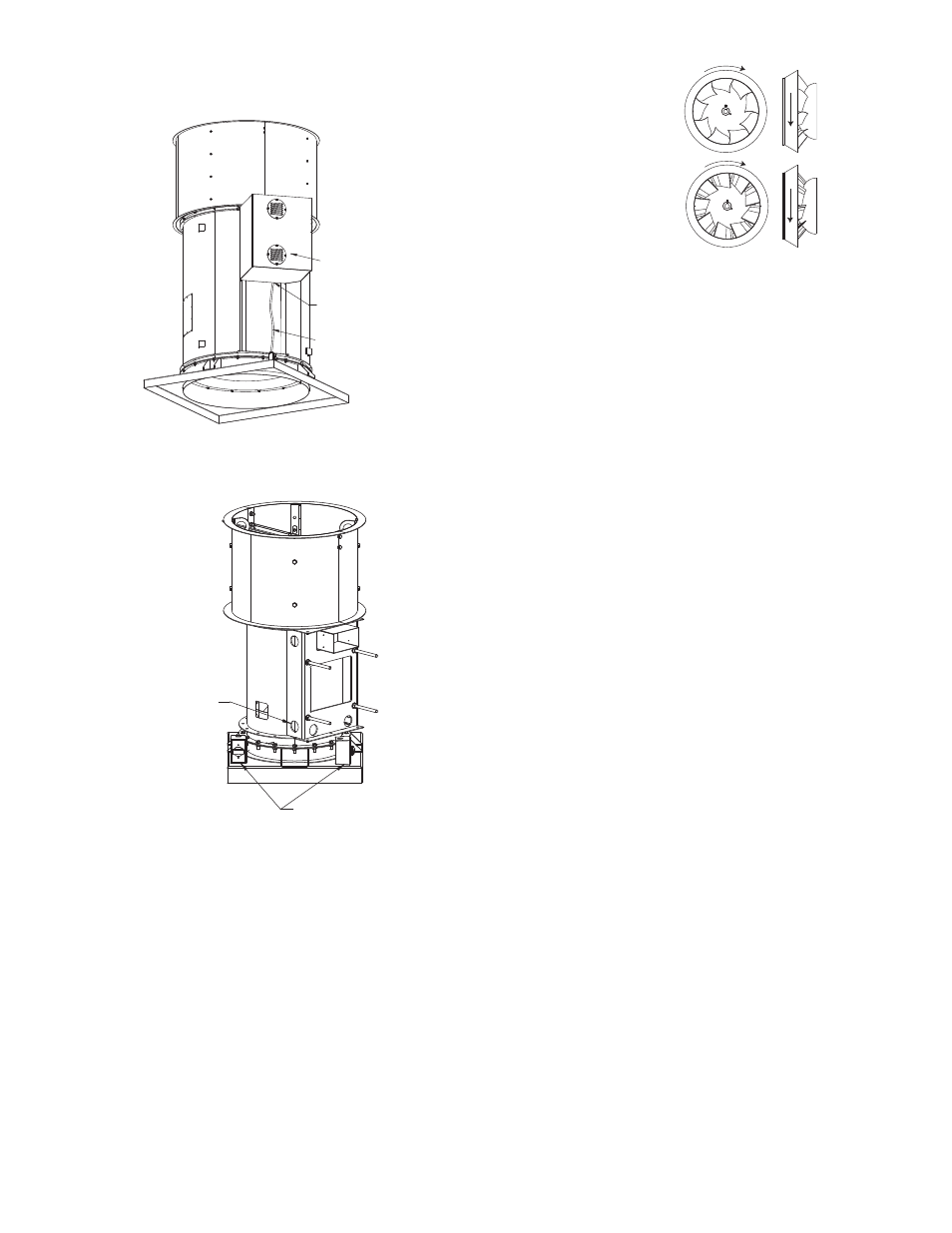

Typical Wiring Path for Roof Mounted Units

For sizes 135-600, route conduit under motor cover

between the motor support rails and out to enclosure as

shown in Figure 1 below.

For sizes 90-120, route conduit through holes in the

sides of the motor support saddle as shown in Figure 2

below.

Wheel Rotation

Test the fan to ensure the rotation of the wheel is the

same as indicated by the arrow marked Rotation.

115 and 230 Single Phase Motors

Fan wheel rotation is set correctly at the factory. Chang-

ing the rotation of this type of motor should only be

attempted by a qualified electrician.

208, 230, and 460, 3 Phase Motors

These motors are electrically reversible by switching

two of the supply leads. For this reason, the rotation of the

fan cannot be restricted to one direction at the factory. See

Wiring Diagrams for specific information on reversing

wheel direction.

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious dam-

age. For 3-phase motors, if the fan is running in the

wrong direction, check the control switch. It is possi-

Weather Cover

Liquidtite

Size 135-600, Run

Liquidtite Between

Weather Cover and Unit

Figure 1

Enclosure May Be Located

in Either Corner

(Liquidtite Not Shown)

90-120, Run

Liquidtite Through

Holes in Saddle

Figure 2

ble to interchange two leads at this location so that the

fan is operating in the correct direction.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten accord-

ing to the recommended torque shown in the table

Recommended Torque for Setscrews/Bolts.

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power

sources.

b. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

c. Inspect belt tension and pulley alignment.

d. Inspect motor wiring.

e. Ensure belt touches only the pulley.

f. Ensure fan and ductwork are clean and free of debris.

g. Inspect wheel-to-inlet clearance. The correct wheel-

to-inlet clearance is critical to proper fan performance.

h. Close and secure all access doors.

g. Restore power to the fan.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for squeal-

ing).

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. See Troubleshooting.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the Conditions Chart.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

QMX

QMX-HP