Duct and damper, Duct and damper installation – COOK QMX User Manual

Page 2

2

Correct

Incorrect

MIN

3 DIA

duct diameter of straight duct before placing an elbow or

damper. Clearance is also required on the inlet and outlet

for maintenance such as pulley or bearing replacement.

Non-Ducted Inlet Clearance

If your fan has an open inlet (no duct work), the fan must

be placed 1 effective wheel diameter away from walls and

bulkheads.

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efficiency because it doesn’t allow for a static regain.

Inlet Duct Turns

For ducted inlets, allow at least 3 effective wheel diame-

ters between duct turns or elbows and the fan inlet.

Discharge Duct Turns

Where possible, allow 3 duct diameters between duct

turns or elbows and the fan outlet. Refer to the drawing

below.

Non-ducted Inlet Clearance

MIN

1 DIA

Free Discharge

Correct

Incorrect

Correct

Incorrect

MIN

3 DIA

Inlet Duct Turns

d. Adjust the isolators by turning the leveling nut counter

clockwise several turns at a time alternately on each

isolator until the fan weight is transferred onto the iso-

lators and the fan raises uniformly off the blocks. Then

remove the blocks.

e. Turn lock nut onto leveling bolt and secure firmly in

place against the top of the mounting flange or frame.

f. Secure isolators to mounting surface.

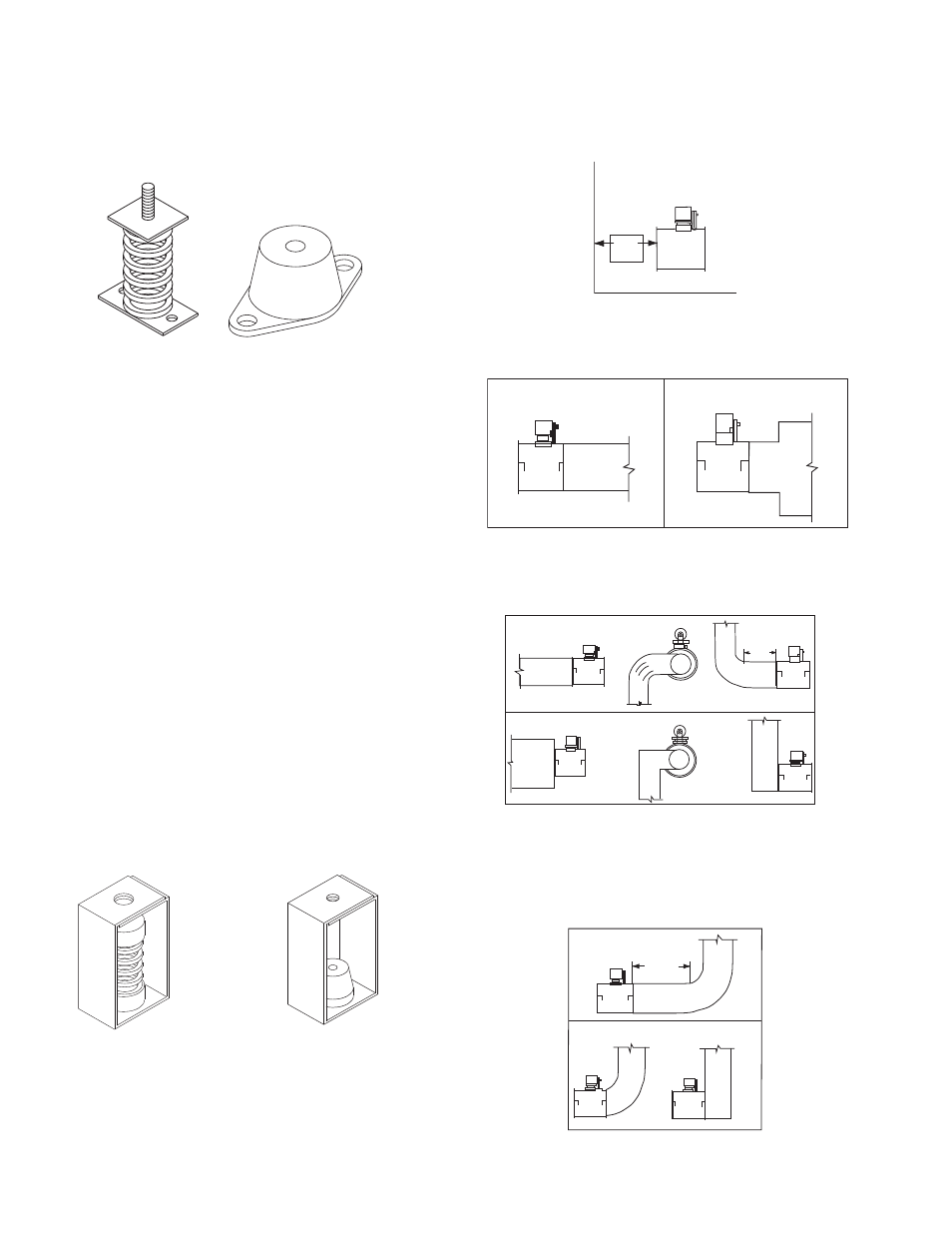

Floor Mounted Rubber-In-Shear (RIS) Isolators

a. Mount fan on isolation base or rails (if supplied).

b. Elevate fan to provide room to insert isolators

between the fan and foundation and block in position.

c. Position isolators under fan and secure bolts.

d. Remove blocks and allow fan to rest on floor. Isolators

must be installed on a level surface (leveling should

not be required).

e. Secure isolators to mounting surface.

Ceiling Mounted Spring and Rubber-in-Shear (RIS) Iso-

lators

a. Elevate fan to operating height and brace.

b. Attach threaded rod to overhead support structure

directly above each mounting hole. Rod should extend

to within a few feet of fan.

c. Attach isolator to end of threaded rod using a nut on

each side of isolator bracket.

d. Insert another section of threaded rod through the fan

mounting hole and isolator.

e. Attach two nuts to threaded rod in isolator.

f. Place adjusting nut and locking nut on threaded rod

near fan mounting bracket.

g. Alternately rotate adjusting nut at each mounting loca-

tion until the fan weight is uniformly transferred to the

isolators. Remove bracing.

Duct and Damper Installation

Efficient fan performance relies on the proper installation

of inlet and discharge ducts, as well as dampers. Be sure

your fan conforms to the guidelines below and allows 3

Figure 1 -Floor Mount Isolators

Rubber-In-Shear Isolator

Spring Isolator

Rubber-In-Shear Ceiling Isolators

Ceiling Mounted Spring Isolator

Figure 2 - Ceiling Mount Isolators

Discharge Duct Turns