Wheel replacement for tcn & tcnh, Maximum rpm – COOK TCN User Manual

Page 7

7

allow proper alignment. Care should be taken to insure

that inlet cone is centered inside wheel before and

after tightening attaching bolts.

n. Slide wheel on shaft to achieve proper wheel/inlet

overlap. Refer to Wheel-to-Inlet Clearance on page 3.

o. Replace and tighten belts.

p. Test run the fan.

q. Re-tighten setscrews on bearings, sheave, and

wheel. Recheck belt tension and adjust as needed.

r. Replace bearing cover.

s. Trim balance as necessary (.0785 in/sec max.).

Wheel Replacement for TCN & TCNH

TCN

a. Drill two 1/4” diameter holes, 180

apart centered

approximately between the shaft and the outside

diameter of the hub, 3/8” to 1/2” in depth.

b. Tap 1/4” holes to 5/16” thread with a 5/16” hole tap.

Do not drill or tap greater than recommended.

c. Screw the puller arms to the full depth of the threads

into the tapped holes. Align center of the puller with

the center of the shaft. Ensure all setscrews in the

hub, normally two, are fully removed.

d. Slowly remove wheel from the shaft.

Recommended Puller

Lisle No. 45000 Sterling Wheel Puller. This puller is

available at most automotive parts retail outlets.

TCNH

The TCNH wheel has a pre-machined shoulder in the

hub for the use of most 2 and 3 jaw mechanical puller.

a. Align center of the puller with the center of the shaft.

b. Ensure all setscrews in the hub, normally two, are

fully removed.

c. Slowly remove wheel from the shaft.

After replacement trim balance as necessary (.0785 in/

sec max.).

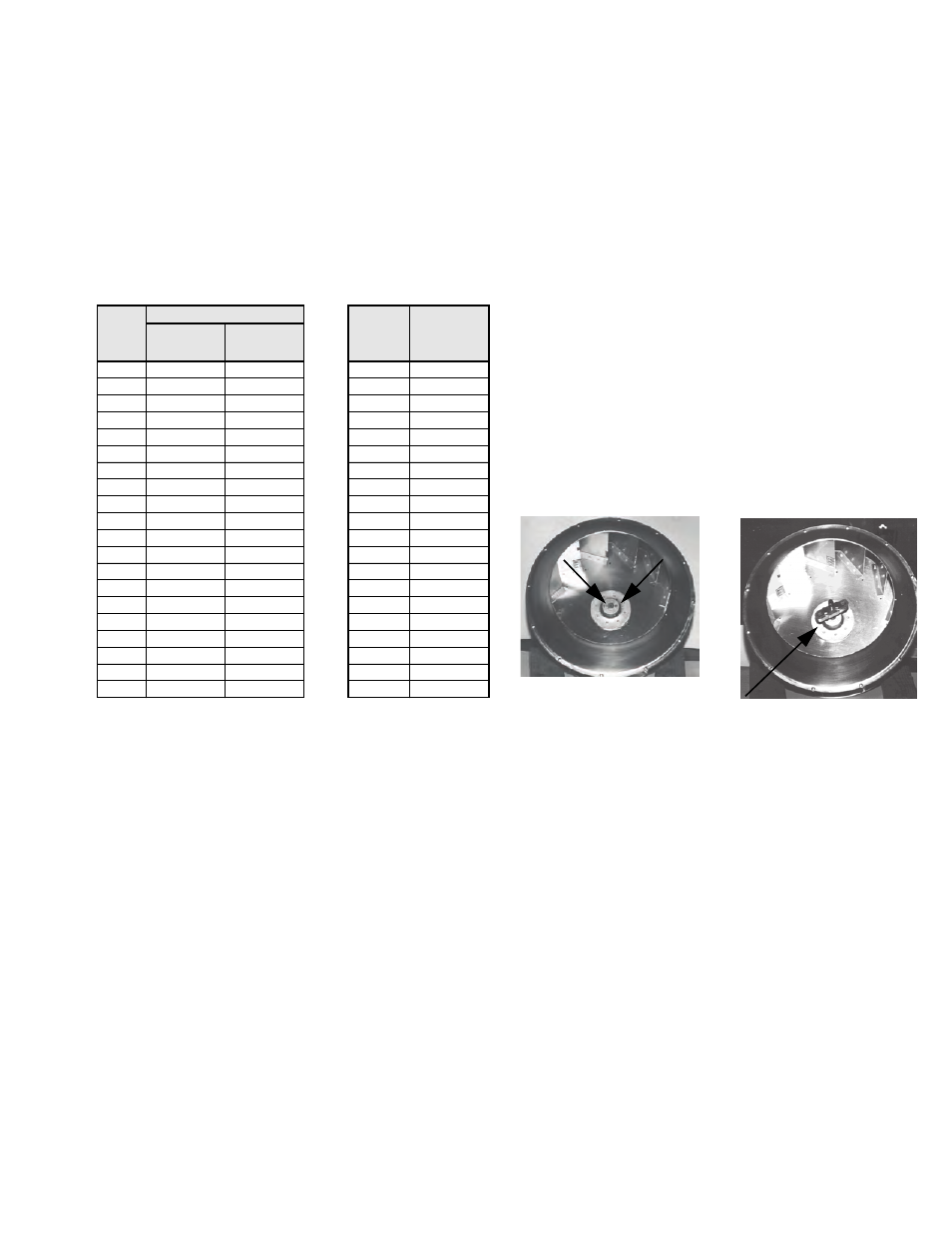

Above - Drilled hole placement.

Right - Wheel puller.

c. Clean the motor and fan shafts.

d. Clean bores of pulleys and coat the bores with heavy

oil.

e. Remove grease, rust, or burrs from the pulleys and

shafts.

f. Remove burrs from shaft by sanding.

g. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

h. Tighten in place.

i. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Loosen and remove belts by lowering motor mounting

plate with the four adjusting nuts.

b. Remove the bearing cover by removing the four bolts

around the perimeter of the bearing cover. NOTICE!

Do not remove fan sheave yet.

c. Remove inlet cone by removing attaching bolts/nuts

around perimeter of the inlet plate.

d. Remove wheel by loosening setscrews and sliding off

shaft.

e. Record the location of the fan sheave from end of

shaft, and remove the sheave.

f. Record the distance from the bearing to the end of the

shaft.

g. Loosen setscrews on bearings and remove shaft.

h. Remove bearings and rubring and replace with new

bearings.

i. Slide shaft through bearings until shaft protrudes the

same amount as original shaft. Tighten setscrews.

j. Replace Rubring.

k. Replace fan sheave in original location.

l. Replace wheel but do not tighten yet.

m. Replace inlet cone. Wheel may need to be moved to

Maximum RPM

TCN-B

Size

Maximum RPM

TCNH-B

Size

Maximum

RPM

Non

Reinforced

Wheel

Reinforced

Wheel

60

3942

-

60

4100

70

3942

-

70

4100

80

3942

-

80

4100

100

3942

-

100

4100

120

3047

-

120

3757

135

2375

-

135

2950

150

2116

2269

150

2647

165

1766

2138

165

2412

180

1610

1850

180

2388

195

1429

1663

195

2198

210

1277

1435

210

1926

225

1152

1569

225

1773

245

1015

1530

245

1559

270

876

1287

270

1414

300

837

1072

300

1247

330

716

1026

330

1173

365

624

835

365

1025

402

539

707

402

925

445

463

684

445

842

490

630

582

490

762