Bearings, Services, Speed – COOK TCN User Manual

Page 6: Replacement, Lubrication - fan bearings, Lubrication - motor bearings, Motor services, Changing shaft speed, Pulley and belt replace- ment

6

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect variable inlet vanes for freedom of operation

and excessive wear. The vane position should agree

with the position of the control arm. As the variable inlet

vanes close, the entering air should spin in the same

direction as the wheel.

• Inspect springs and rubber isolators for deterioration

and replace as needed.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel

and housing prevent imbalance and damage.

Lubrication - Fan Bearings

TCN bearings are lubricated through a grease fitting on

the bearing and should be lubricated by the schedule,

Lubrication Conditions Chart.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can burst

seals thus reducing bearing life.

In the event the bearing cannot be seen, use no more

than three injections with a hand-operated grease gun.

Before lubricating, the grease nipple and immediate

vicinity should be thoroughly cleaned without the use of

high pressure equipment. The grease should be supplied

slowly as the bearing rotates until fresh grease slips past

the seal. Excessive pressure should be avoided to prevent

seal damage.

Exceptions to the greasing interval chart:

• Periodic Applications (any break of one week or

more): it is recommended that full lubrication be per-

formed prior to each break in operation.

• Higher Temperature: it is recommended to halve the

intervals for every 30

F increase in operating tempera-

ture above 120

F not to exceed 230F for standard

bearings; High Temperature bearings (optional) can

operate up to 400

F.

• Vertical Shaft: it is recommended that the intervals

should be halved.

NOTICE! Loren Cook Company uses petroleum lubri-

cant in a lithium base. Other types of grease should

not be used unless the bearings and lines have been

flushed clean. If another type of grease is used, it

should be a lithium-based grease conforming to NLGI

grade 2 consistency. A NLGI grade 2 grease is a light

viscosity, low-torque, rust-inhibiting lubricant that is

water resistant. Its temperature range is from -30

F to

+200

F and capable of intermittent highs of +250F.

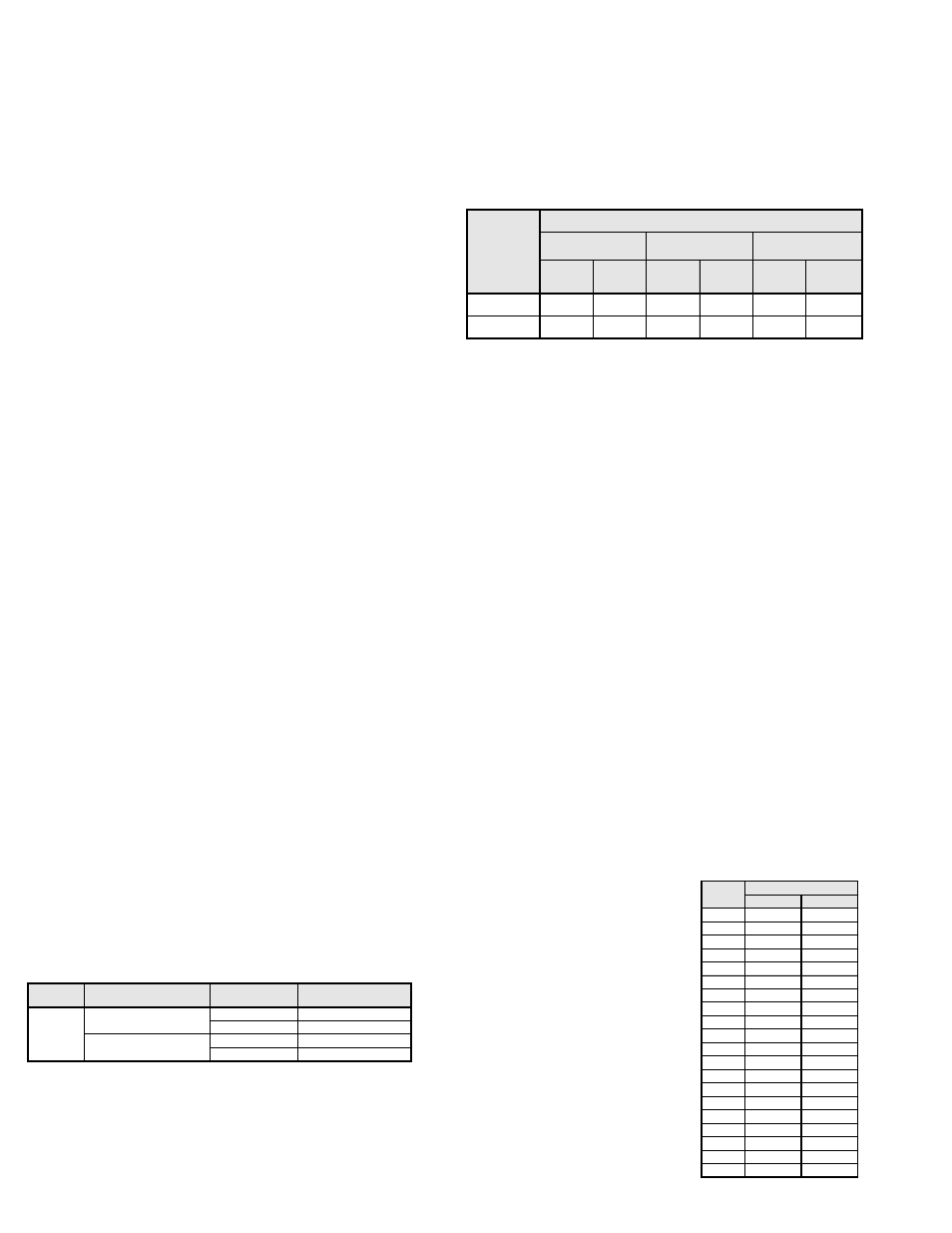

Lubrication Conditions Chart

Lubrication - Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below.

Motor bearings without provisions for relubrication will

Fan Class

Fan Status

Shaft Size

Maximum Interval

(operational hrs)

TCN

Inline

Blowers

Normal Conditions

(Clean, Dry & Smooth)

> 1-1/2”

10,000

< 1-1/2”

2,000

Extreme Conditions

(Dirty/Wet/Rough)

> 1-1/2”

2,000

< 1-1/2”

400

operate up to 10 years under normal conditions with no

maintenance. In severe applications, high temperatures or

excessive contaminates, it is advisable to have the mainte-

nance department disassemble and lubricate the bearings

after 3 years of operation to prevent interruption of service.

For motors with provisions for relubrication, follow inter-

vals of the following table.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with a

compatible grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that

the belt rides higher in the

groove (larger pitch diameter).

Ensure that the RPM limits of

the fan and the horsepower

limits of the motor are main-

tained.

Pulley and Belt Replace-

ment

a. Loosen and remove belts by

lowering motor mounting

plate with the four adjusting

nuts.

b. Remove pulleys from their

respective shafts.

Relubrication Intervals

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

Standard

3 yrs.

6 months

2 yrs.

6 months

1 yr.

3 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months

Fan

Size

Max Catalog RPM

TCN

TCNH

60

3899

4231

70

3942

4231

80

3600

4231

100

3382

4231

120

2894

3692

135

2305

2953

150

2162

2656

165

2092

2414

180

1817

2389

195

1578

2204

210

1404

1786

225

1534

1659

245

1485

1532

270

1250

1391

300

1038

1251

330

978

1141

365

817

1022

402

694

894

445

672

846

490

573

770